335345435

jan . 13, 2025 15:31 Back to list

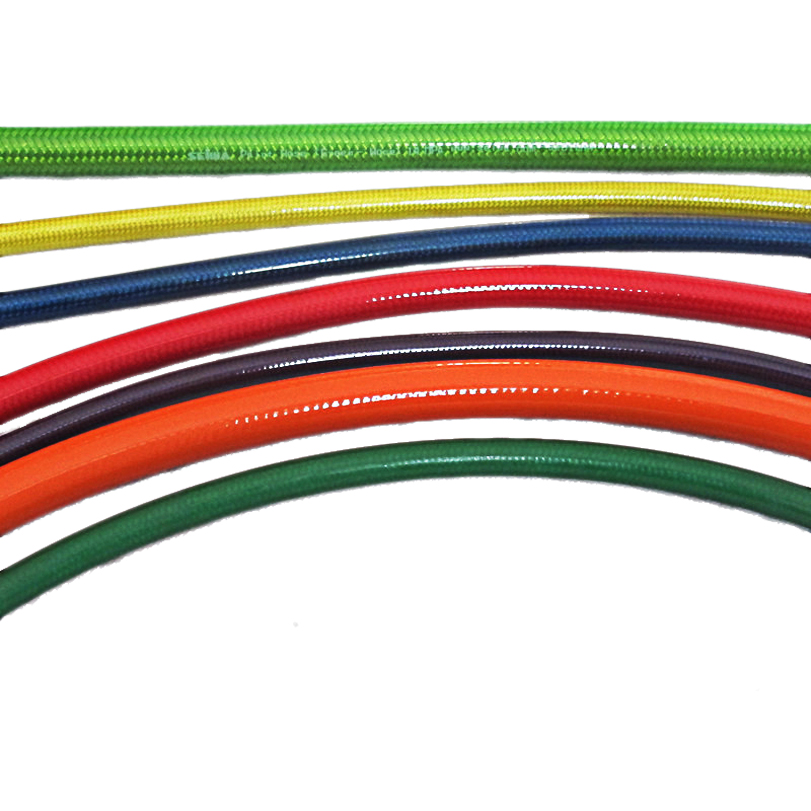

suction hose

Suction hoses are integral components in numerous industrial and domestic applications. Selecting the appropriate suction hose can significantly impact the efficiency and longevity of your operations. With decades of experience in the field, I’ve witnessed firsthand the evolution of these products and the impact the right selection can make.

The durability of suction hoses cannot be overstated. Wear and tear can lead to costly downtime and repairs or even catastrophic failures that might jeopardize safety or environmental standards. Opting for high-grade materials, such as rubber with protective coatings, ensures extended life spans even in harsh conditions. Practical experience shows that companies often underestimate the importance of maintenance; regular inspections and cleaning can prevent blockages and wear, thus extending the service life of the hose. Supplier reputation also contributes significantly to product trustworthiness. Established manufacturers and suppliers usually offer warranties, compliance certifications, and detailed product information that verify the hose’s suitability for specific applications. These authoritative assurances are invaluable, especially when investing in hoses for critical operations. In terms of installation and use, real-world experiences underline the necessity of proper training for handling hoses — particularly in high-stakes industries. Mishandling can compromise performance and safety, underscoring the importance of utilizing expert guidance during both installation and operation. Ultimately, selecting a suction hose that meets the specific demands of your application is an informed decision that goes beyond mere price comparison. It requires a careful balance of technical knowledge, real-world experience, and a commitment to safety and reliability. Investing in quality hoses tailored to your exact needs ensures operational efficiency and long-term success.

The durability of suction hoses cannot be overstated. Wear and tear can lead to costly downtime and repairs or even catastrophic failures that might jeopardize safety or environmental standards. Opting for high-grade materials, such as rubber with protective coatings, ensures extended life spans even in harsh conditions. Practical experience shows that companies often underestimate the importance of maintenance; regular inspections and cleaning can prevent blockages and wear, thus extending the service life of the hose. Supplier reputation also contributes significantly to product trustworthiness. Established manufacturers and suppliers usually offer warranties, compliance certifications, and detailed product information that verify the hose’s suitability for specific applications. These authoritative assurances are invaluable, especially when investing in hoses for critical operations. In terms of installation and use, real-world experiences underline the necessity of proper training for handling hoses — particularly in high-stakes industries. Mishandling can compromise performance and safety, underscoring the importance of utilizing expert guidance during both installation and operation. Ultimately, selecting a suction hose that meets the specific demands of your application is an informed decision that goes beyond mere price comparison. It requires a careful balance of technical knowledge, real-world experience, and a commitment to safety and reliability. Investing in quality hoses tailored to your exact needs ensures operational efficiency and long-term success.

Share

Latest news

-

Premium Distribution PTFE Hose | Flexible & Stainless Braided

NewsAug.23,2025

-

Premium Distribution PTFE Hose: Flexible & Durable Solutions

NewsAug.22,2025

-

SAE 100 R3 / EN854 R3 Hydraulic Hose | Medium Pressure & Flexible

NewsAug.11,2025

-

EN856 4SP Hydraulic Hose: High-Pressure & Durable Solutions

NewsAug.11,2025

-

Premium Soft Rubber Tubing: Flexible & Durable Hose Solutions

NewsAug.10,2025

-

Premium Distribution PTFE Hose | Flexible & Durable Solutions

NewsAug.09,2025