335345435

okt . 01, 2024 19:00 Back to list

Top Manufacturers of Steel Braided Teflon Hoses for High-Performance Applications

The Rise of Steel Braided Teflon Hose Manufacturers

In recent years, the demand for high-performance hoses in various industries has surged, leading to the emergence of specialized manufacturers focusing on steel braided Teflon hoses. These hoses are known for their exceptional thermal stability, chemical resistance, and mechanical strength, making them ideal for demanding applications in the automotive, aerospace, food processing, and chemical industries.

Understanding Steel Braided Teflon Hoses

Teflon, or polytetrafluoroethylene (PTFE), is a versatile polymer that boasts a wide temperature range, from -320°F to +500°F, and is largely resistant to corrosive chemicals. When combined with a steel braided exterior, Teflon hoses gain added durability and pressure resistance. The steel braid serves as a reinforcement, enhancing the hose's structural integrity and allowing it to withstand high pressures without collapsing.

These hoses are particularly beneficial in applications where flexibility and chemical resistance are paramount. For instance, they are commonly used in hydraulic systems and fuel lines where exposure to harsh fluids can lead to material degradation. The combination of Teflon’s non-stick properties and the steel braid’s robustness ensures reliable performance and longevity.

The Manufacturing Process

Manufacturing high-quality steel braided Teflon hoses involves several intricate steps. Initially, manufacturers begin with extruding Teflon to form the inner tubing. Following this, a steel braid is woven around the Teflon core for reinforcement. This process requires precision to ensure that the steel braid is evenly distributed, thereby enhancing the hose's performance under pressure.

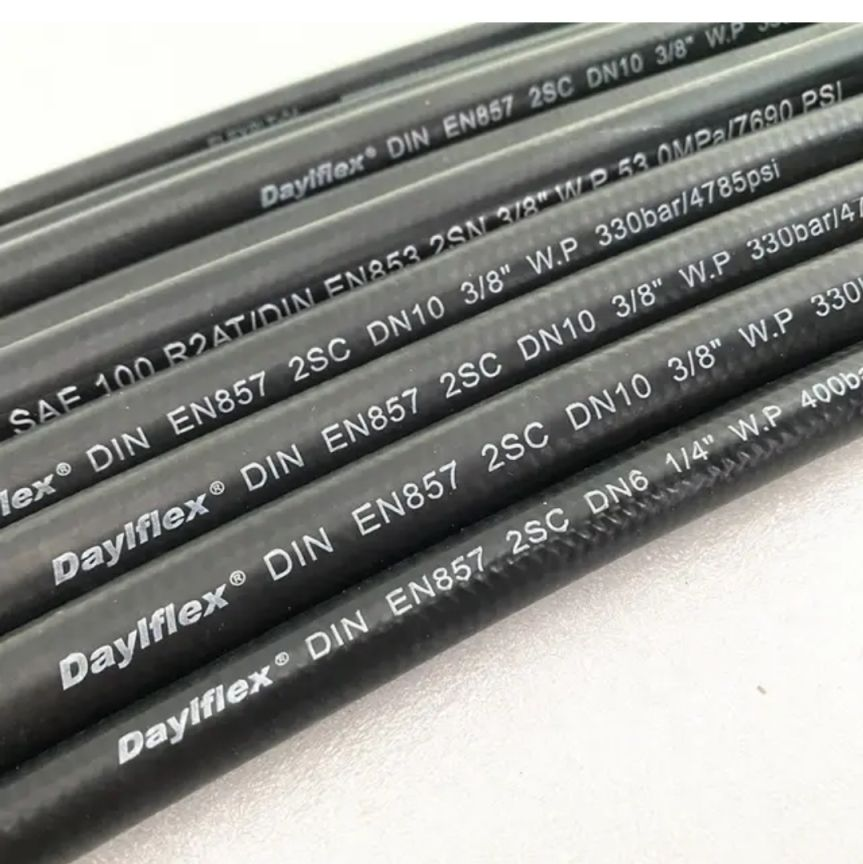

steel braided teflon hose manufacturers

Once the braiding is complete, the end fittings are attached, which are typically made from stainless steel to maintain compatibility with the Teflon and to resist corrosion. Finally, the hoses undergo rigorous testing to meet industry standards, ensuring that they can withstand high temperatures and pressures without failure.

Market Trends and Innovations

The market for steel braided Teflon hoses is continuously evolving. Innovations in manufacturing techniques have led to the development of lightweight and more flexible hoses, which significantly enhance usability in tight spaces without compromising on strength. Furthermore, as industries focus on sustainability, manufacturers are exploring environmentally friendly practices and materials in the hose production process.

Consumer preferences are also shifting towards custom solutions. Manufacturers are increasingly offering tailored products, enabling businesses to meet specific requirements, from unique sizes to specialized chemistries that can handle specific fluids.

Conclusion

As industries continue to advance, the role of steel braided Teflon hose manufacturers becomes increasingly vital. Their ability to produce high-performance, durable, and reliable hoses ensures that businesses can operate efficiently and safely. With ongoing innovations and a commitment to sustainability, the future looks bright for manufacturers in this sector, ushering in a new era of performance and reliability in hose technology. Whether in automotive applications or chemical processing, the value of steel braided Teflon hoses cannot be overstated, and their importance will only grow in the years to come.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025