335345435

nov . 09, 2024 14:29 Back to list

OEM High Pressure LPG Hose Manufacturing and Supply Solutions for Various Industries

The Importance of High-Pressure LPG Hoses in Industrial Applications

In the modern industrial landscape, the need for reliable and efficient transportation of gases is paramount. One of the most critical components in this domain is the high-pressure liquefied petroleum gas (LPG) hose. Many factories specialize in the production of OEM (Original Equipment Manufacturer) high-pressure LPG hoses designed to withstand the rigors of industrial applications. Understanding what these hoses are and their significance can help businesses make informed decisions about their gas transportation systems.

Understanding LPG Hoses

LPG hoses are specifically designed to transport liquefied petroleum gas, which is a mixture of propane and butane. These hoses are built to handle the high pressures associated with LPG as it is transported from storage tanks to various applications, such as heating, cooking, or fueling engines. High-pressure hoses are engineered to prevent leaks, ensure safety, and maintain a consistent flow of gas under varying conditions.

Manufacturing Process and Standards

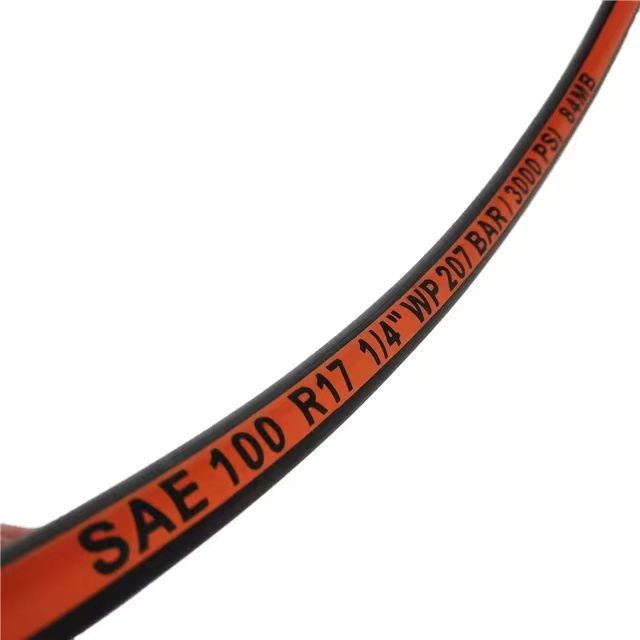

OEM high-pressure LPG hose factories adhere to strict manufacturing standards to ensure product quality and safety. The hoses are typically constructed from durable materials, such as synthetic rubber and reinforced with layers of textile or steel braid. This construction allows them to withstand high pressure and resist wear and tear over time.

Quality assurance is an integral part of the production process. Factories conduct rigorous testing on their hoses, including pressure tests and leak tests, to ensure they meet international standards such as ISO and EN. These certifications guarantee that the hoses can perform reliably in demanding environments.

Applications in Various Industries

oem high pressure lpg hose factories

High-pressure LPG hoses are employed in a wide range of industries. In the residential sector, they are commonly used for home heating and cooking appliances. In commercial settings, they are essential for restaurants and hotels that rely on LPG for their cooking needs.

Moreover, industrial applications such as manufacturing and construction often require the use of high-pressure hoses to power equipment and machinery. For instance, in the welding and metalworking industries, LPG is frequently used as a fuel source, making high-quality hoses crucial for safety and operational efficiency.

Safety Considerations

The importance of safety in the use of high-pressure LPG hoses cannot be overstated. Leaks or failures in hoses can lead to catastrophic incidents, including fires or explosions. Therefore, regular inspection and maintenance of LPG hoses are essential. Businesses must ensure that the hoses are replaced at the end of their service life or if any signs of wear and tear are detected.

Furthermore, proper installation and adherence to safety guidelines are critical. Training employees on the correct handling and use of LPG hoses can significantly reduce risks and enhance overall safety in the workplace.

Conclusion

In conclusion, OEM high-pressure LPG hoses play a vital role in the safe and efficient transport of gas across various industries. The commitment of manufacturers to adhere to stringent quality standards ensures that these hoses can withstand the demands of high-pressure applications. By prioritizing safety and reliability, businesses can foster a secure environment while optimizing their operations. As industries continue to evolve, the significance of high-quality LPG hoses will undoubtedly remain a cornerstone of modern gas management systems. Investing in the right equipment not only ensures compliance with safety regulations but also enhances productivity and operational efficiency.

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025