335345435

jan . 20, 2025 05:53 Back to list

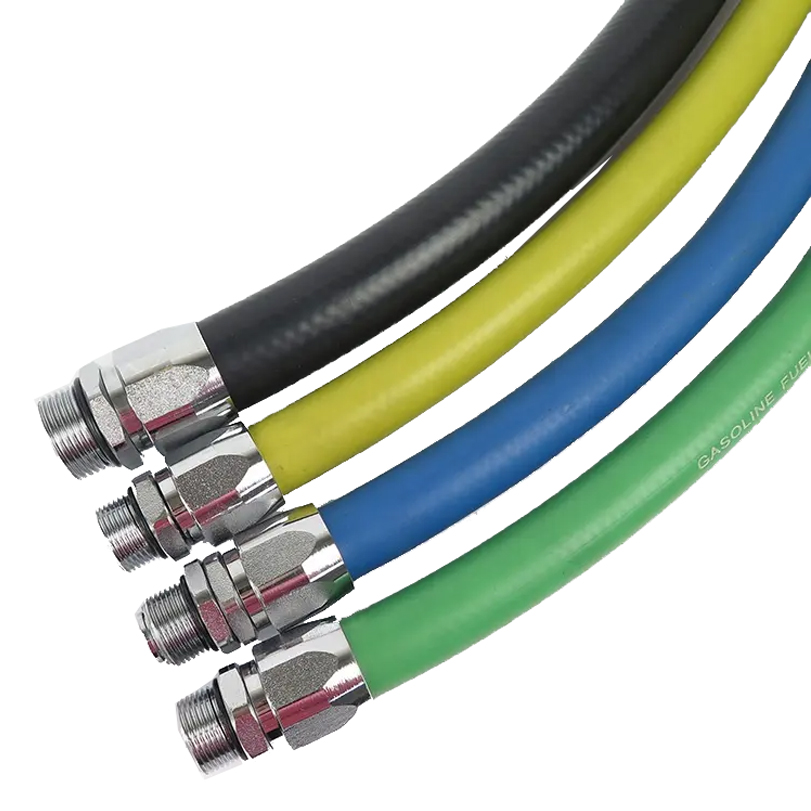

hydraulic hose end fittings manufacturers

In the world of hydraulic systems, where power and precision are crucial, the role of hydraulic hose end fittings manufacturers stands paramount. These components, though small, bear significant responsibility in ensuring the effectiveness and reliability of hydraulic assemblies. From mobile equipment to industrial machinery, the expertise and trustworthiness of these manufacturers directly influence operational success.

When selecting a hydraulic hose end fittings manufacturer, discerning buyers should assess the company’s reputation for quality and adherence to industry standards such as ISO 9001. A manufacturer’s track record of timely delivery, responsive customer service, and technical support is crucial for maintaining operational fluidity in businesses reliant on hydraulic systems. Trusted manufacturers foster partnerships built on clear communication and mutual respect, forming the backbone of successful and long-lasting collaborations. The authority and expertise of a seasoned manufacturer are further underscored by their ability to customize solutions tailored to unique customer requirements. Whether developing proprietary designs or standard off-the-shelf products, these manufacturers exhibit unparalleled flexibility and ingenuity. This bespoke approach ensures that solutions fit seamlessly into the particularities of equipment designs and operational goals. Furthermore, the most credible manufacturers stay ahead of industry trends, offering insights into everything from emerging material technologies to evolving safety regulations. By anticipating changes and preparing clients for future challenges, they cultivate sustained relationships grounded in value and foresight. Ultimately, the authenticity of a hydraulic hose end fittings manufacturer is confirmed by their holistic commitment to quality, innovation, and customer satisfaction, all while maintaining stringent control across their production processes. This dedication is not just a hallmark of reliability; it is a promise of excellence that assures clients of the manufacturer's capacity to deliver products that drive efficiency and success. The intricate world of hydraulic hose end fittings manufacturing is not merely about creating components; it’s about weaving a narrative of precision, expertise, and trustworthiness, ensuring that hydraulic systems across the globe operate with the utmost reliability and performance. With experience, expertise, authoritativeness, and trustworthiness as guiding principles, these manufacturers establish themselves as pivotal contributors to the thriving landscape of hydraulic technology.

When selecting a hydraulic hose end fittings manufacturer, discerning buyers should assess the company’s reputation for quality and adherence to industry standards such as ISO 9001. A manufacturer’s track record of timely delivery, responsive customer service, and technical support is crucial for maintaining operational fluidity in businesses reliant on hydraulic systems. Trusted manufacturers foster partnerships built on clear communication and mutual respect, forming the backbone of successful and long-lasting collaborations. The authority and expertise of a seasoned manufacturer are further underscored by their ability to customize solutions tailored to unique customer requirements. Whether developing proprietary designs or standard off-the-shelf products, these manufacturers exhibit unparalleled flexibility and ingenuity. This bespoke approach ensures that solutions fit seamlessly into the particularities of equipment designs and operational goals. Furthermore, the most credible manufacturers stay ahead of industry trends, offering insights into everything from emerging material technologies to evolving safety regulations. By anticipating changes and preparing clients for future challenges, they cultivate sustained relationships grounded in value and foresight. Ultimately, the authenticity of a hydraulic hose end fittings manufacturer is confirmed by their holistic commitment to quality, innovation, and customer satisfaction, all while maintaining stringent control across their production processes. This dedication is not just a hallmark of reliability; it is a promise of excellence that assures clients of the manufacturer's capacity to deliver products that drive efficiency and success. The intricate world of hydraulic hose end fittings manufacturing is not merely about creating components; it’s about weaving a narrative of precision, expertise, and trustworthiness, ensuring that hydraulic systems across the globe operate with the utmost reliability and performance. With experience, expertise, authoritativeness, and trustworthiness as guiding principles, these manufacturers establish themselves as pivotal contributors to the thriving landscape of hydraulic technology.

Share

Latest news

-

SAE 100 R3 / EN854 R3 Hydraulic Hose | Medium Pressure & Flexible

NewsAug.11,2025

-

EN856 4SP Hydraulic Hose: High-Pressure & Durable Solutions

NewsAug.11,2025

-

Premium Soft Rubber Tubing: Flexible & Durable Hose Solutions

NewsAug.10,2025

-

Premium Distribution PTFE Hose | Flexible & Durable Solutions

NewsAug.09,2025

-

Premium 38mm Hydraulic Hose Factories | Direct & Reliable

NewsAug.08,2025

-

Premium Wire Braided Hydraulic Hose - Steel Reinforced for Durability

NewsAug.07,2025