335345435

sep . 28, 2024 00:13 Back to list

Hydraulic Hose Fittings for Bulkhead Installation and Compatibility

Understanding Hydraulic Hose Bulkhead Fittings

Hydraulic hose bulkhead fittings are crucial components in hydraulic systems, connecting hoses while maintaining a secure and leak-free environment. These fittings are typically made of durable materials like stainless steel, brass, or other high-strength alloys, designed to withstand the high pressures and harsh conditions often encountered in hydraulic applications.

A bulkhead fitting serves as a conduit between two separate areas or compartments, effectively allowing the passage of hydraulic fluid while providing a barrier to prevent leaks. This is particularly important in machinery and equipment where hydraulic systems are often packed into tight spaces. By utilizing bulkhead fittings, engineers can ensure that hoses are securely fastened and do not interfere with other components within the system.

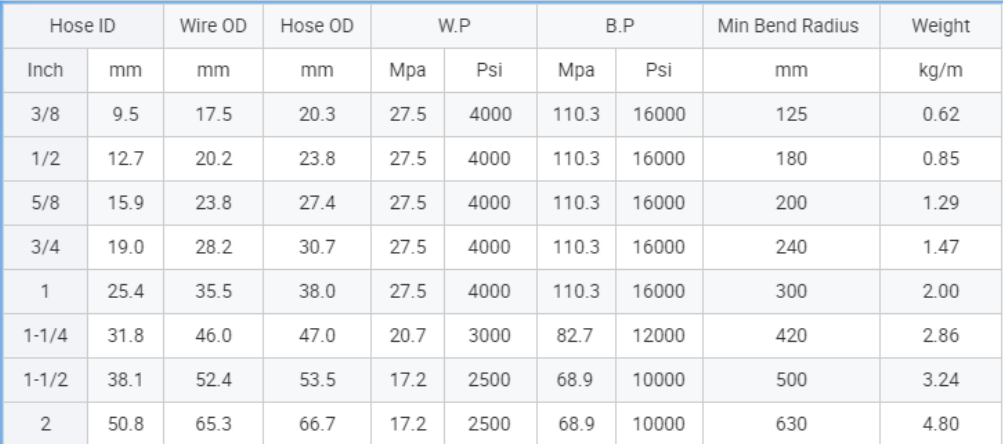

When selecting hydraulic hose bulkhead fittings, several factors must be considered. First, the size and type of the hose being used are critical. Ensuring compatibility between the fitting and the hose is essential to avoid operational failures. Fittings come in various configurations, including straight, elbow, and T-shaped designs, allowing for flexibility in system layout and routing.

hydraulic hose bulkhead fitting

Moreover, pressure ratings are a key consideration. Bulkhead fittings are designed to handle specific pressure levels, and it’s vital to choose fittings that exceed the operating pressure of the hydraulic system. This ensures longevity and reliability, reducing the risk of catastrophic failures that could lead to operational downtimes or safety hazards.

Installation of bulkhead fittings requires careful attention. It is important to follow the manufacturer’s guidelines and utilize the appropriate sealing techniques, such as using O-rings or thread sealants, to prevent leaks. Improper installation can negate the benefits these fittings provide, leading to potential issues in fluid transfer.

In addition to their functional aspects, hydraulic hose bulkhead fittings are readily available in numerous configurations, sizes, and materials from various manufacturers. This diversity allows engineers and technicians to find the ideal fitting for a specific application, whether it's for heavy machinery, automotive systems, or industrial equipment.

In conclusion, hydraulic hose bulkhead fittings play an essential role in the efficiency and safety of hydraulic systems. Their ability to establish a secure connection while preventing leaks makes them an indispensable part of designing and maintaining hydraulic systems. Understanding their specifications and proper installation techniques is crucial for ensuring the optimal performance of any hydraulic application.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025