335345435

dec . 20, 2024 14:15 Back to list

forklift hydraulic hose manufacturer

Understanding the Role of Hydraulic Hose Manufacturers in Forklift Performance

Forklifts play an essential role in various industries, from warehousing to manufacturing, facilitating the movement of materials and products efficiently. However, the effectiveness of a forklift is significantly dependent on its hydraulic system, which relies heavily on hydraulic hoses. As such, the role of hydraulic hose manufacturers cannot be understated; they are at the forefront of ensuring that forklifts operate smoothly and safely.

The Importance of Hydraulic Hoses

Hydraulic hoses are critical components in the hydraulic systems of forklifts. They are responsible for carrying hydraulic fluid from the pump to various parts of the system, allowing for the lifting, lowering, and tilting of loads. The reliability and efficiency of these hoses directly impact the performance of the forklift. If the hoses are worn, damaged, or of poor quality, it can lead to leaks, inefficiencies, and potentially dangerous situations.

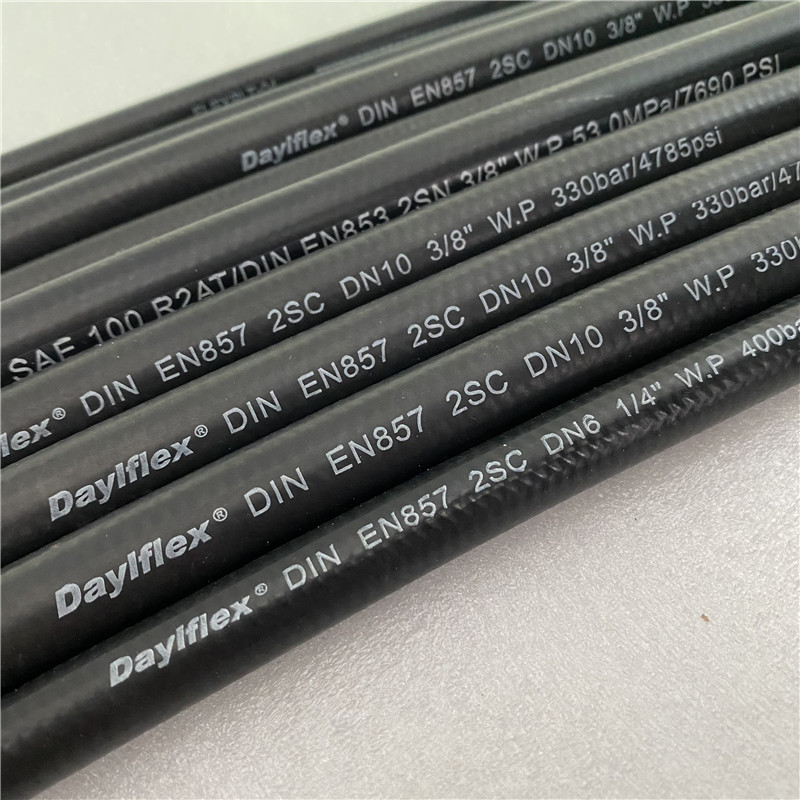

Given the stresses that hydraulic hoses endure—high pressure, exposure to heat, and varying environmental conditions—it is crucial for manufacturers to produce hoses that meet rigorous industry standards. High-quality hydraulic hoses must be durable, flexible, and resistant to abrasion, aging, and external factors such as chemical exposure.

Choosing the Right Manufacturer

When selecting a hydraulic hose manufacturer for forklifts, several factors should be considered

1. Quality Standards It is essential to choose manufacturers who adhere to recognized quality standards, such as ISO 9001. These certifications indicate that the manufacturer follows stringent quality control processes in their production methods.

2. Material Selection The materials used to fabricate hydraulic hoses significantly affect their performance and longevity. A good manufacturer will use high-grade synthetic rubber and armoring materials, increasing resistance to wear and tear.

3. Customization Options Different forklifts may require different specifications for hydraulic hoses. A manufacturer that offers customization options can provide hoses tailored to fit specific models and operational needs.

4. Testing and Compliance The best manufacturers conduct rigorous testing on their products to ensure they can withstand the pressures and conditions expected in real-world applications. Hoses should comply with industry standards such as SAE J517 or EN 853, which outline performance requirements for hydraulic hoses.

forklift hydraulic hose manufacturer

5. Experience and Reputation Manufacturers with extensive experience in the industry are more likely to understand the nuances of hydraulic systems in forklifts. Checking customer reviews and case studies can provide insight into a manufacturer’s reputation and the reliability of their products.

The Manufacturing Process

The manufacturing of hydraulic hoses involves several key steps

- Material Preparation High-quality rubber and materials are selected and prepared for processing.

- Extrusion The rubber is extruded into the desired shape, forming the hose.

- Reinforcement Steel wire or textile layers are added to enhance the strength and pressure tolerance of the hose.

- Curing The hoses undergo a curing process to improve their elasticity and durability. This involves heating the hoses in a controlled environment.

- Quality Control Each batch of hoses is subjected to rigorous quality tests, including pressure testing and examination for defects.

- Packaging and Delivery Once approved, the hoses are carefully packaged and delivered to clients or distributors.

Conclusion

In summary, the role of hydraulic hose manufacturers in the forklift industry is critical for ensuring operational efficiency and safety. With the right hoses, forklifts can perform their tasks with reliability and speed. By selecting reputable manufacturers that prioritize quality, customization, and compliance, businesses can significantly enhance their material handling capabilities. As industries continue to evolve, the demand for high-performance hydraulic hoses will only grow, making the choice of manufacturer a vital consideration for forklift operators worldwide. Investing in quality hydraulic hoses is an investment in the overall performance and safety of any material handling operation.

-

Premium Hydraulic Hose Wholesale | Bulk Savings & Durability

NewsAug.02,2025

-

Premium Chemical Resistant Distribution PTFE Hose

NewsAug.01,2025

-

Industrial Distribution PTFE Hose - High Purity & Flexibility

NewsJul.31,2025

-

Durable Twin Hydraulic Hose for High-Pressure Systems

NewsJul.31,2025

-

Discount Hydraulic Hose Factories – Bulk Supply & Quality Assurance

NewsJul.30,2025

-

Hydraulic Hose Crimping Machine for Precise & Durable Connections

NewsJul.29,2025