335345435

dec . 22, 2024 08:00 Back to list

en856 4sh supplier

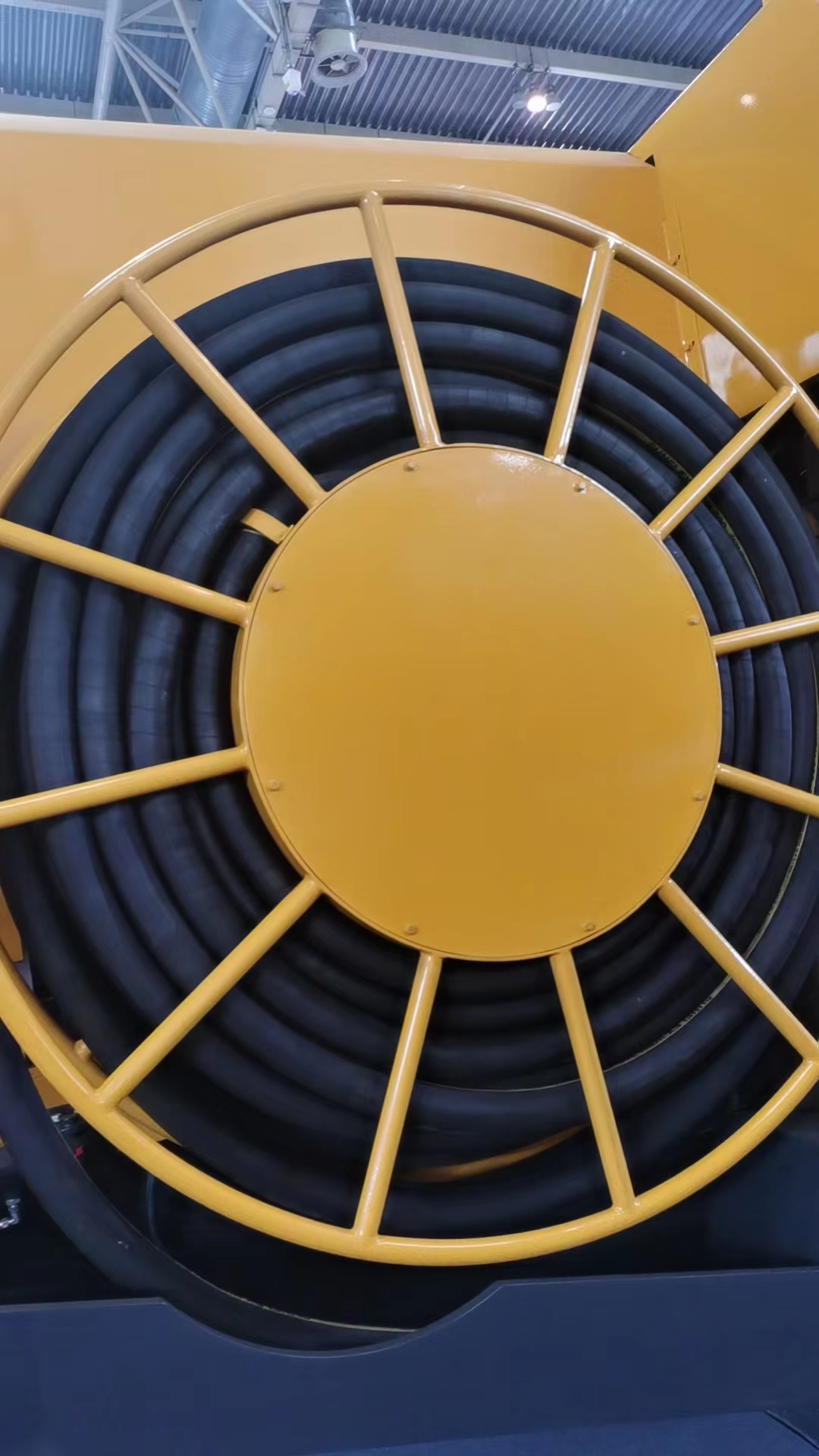

When seeking out reliable suppliers for EN 856 4SH hydraulic hoses, it’s imperative to understand the significance of this specific standard within the hydraulic industry. EN 856 4SH hoses are designed to handle high-pressure hydraulic applications, making them essential in various heavy machinery and equipment used in construction, agriculture, and industrial settings.

Understanding EN 856 4SH

The EN 856 4SH is a European standard that outlines the specifications for four-spiral wire-reinforced hydraulic hoses. The construction of these hoses is robust, comprising multiple layers of high-tensile wire spirals that provide outstanding flexibility and resistance to high pressures, typically ranging from 415 to 530 bar (6,000 to 7,500 psi). Such characteristics enable the hoses to maintain structural integrity even under extreme conditions, ensuring safety and performance.

Importance of Quality Suppliers

Choosing a quality supplier for EN 856 4SH hoses is crucial for several reasons. First, high-quality hoses reduce the risk of failures that can result in downtime and costly repairs. This is particularly important in industries where machinery plays a vital role in daily operations. Reliable suppliers ensure that their products meet the stringent requirements of the EN 856 standard, providing peace of mind to end-users.

Additionally, a reputable supplier will offer detailed specifications and testing reports for their hoses, confirming that they have been manufactured to the highest standards. These documents serve as a testament to the integrity of the products and provide essential information for maintenance and safety protocols.

Evaluating Potential Suppliers

en856 4sh supplier

When evaluating suppliers for EN 856 4SH hoses, consider several factors. Begin by assessing their industry experience and reputation. A supplier with a long-standing presence in the industry is more likely to provide quality products and customer service. Reading reviews and testimonials from other customers can also offer insight into their reliability.

Furthermore, inquire about the supplier’s quality assurance processes. A good supplier will have a rigorous testing protocol in place to ensure that their hoses can withstand the pressures and conditions for which they are intended. Ask about certifications and compliance with international quality standards, as this can further indicate the supplier's commitment to excellence.

Customization and Service Offerings

It is also beneficial to determine if the supplier offers customization options. Depending on your specific application, you may need hoses of different lengths, diameters, or with specific fittings. A flexible supplier who can cater to these requests can significantly simplify procurement and maintenance.

Moreover, consider the level of customer support available. Responsive and knowledgeable customer service can make a significant difference, especially when dealing with urgent supply needs or technical inquiries. A supplier that offers technical advice and support can help you make informed decisions regarding your hydraulic systems.

Conclusion

In conclusion, sourcing EN 856 4SH hoses from a reputable supplier is a critical step in maintaining the efficiency and safety of hydraulic systems. Understanding the specifications of the hoses and the importance of supplier quality will enable businesses to make informed decisions, ensuring reliability and performance in demanding applications. By taking the time to evaluate potential suppliers based on experience, quality assurance, customization capabilities, and customer service, you can establish a fruitful partnership that enhances operational efficiency and reduces the risk of equipment failures. Choose wisely, and your investment in high-quality hydraulic hoses will pay dividends in performance and safety.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025