335345435

okt . 31, 2024 07:00 Back to list

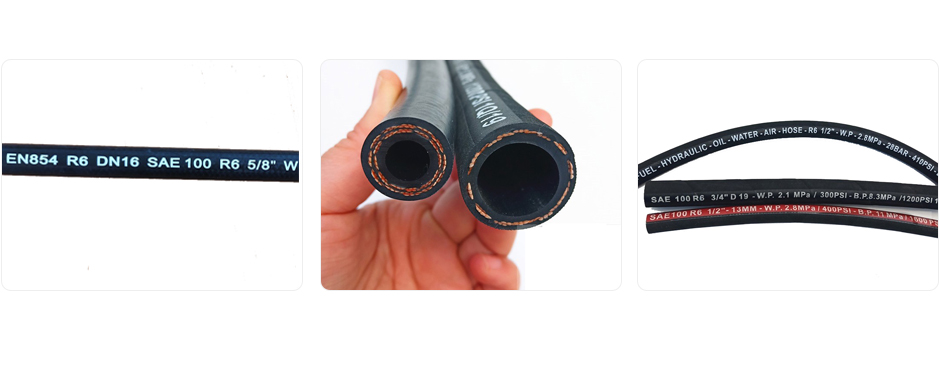

china high pressure rubber hose

High Pressure Rubber Hoses Essential Components in Modern Industries

High pressure rubber hoses play a crucial role in various industrial applications, serving as vital components in the efficient transportation of fluids and gases. Their robust design and flexible nature make them indispensable in sectors such as construction, automotive, agriculture, and manufacturing. This article explores the significance, features, and applications of high pressure rubber hoses.

What Are High Pressure Rubber Hoses?

High pressure rubber hoses are specially engineered tubes made from synthetic rubber or rubber blends that can withstand elevated internal pressures. These hoses are designed to transport fluids like oil, water, air, and chemicals in a range of environments, ensuring safety and efficiency. The construction of these hoses includes multiple layers, incorporating reinforcements such as polyester or steel wire to enhance their strength and durability.

Key Features

1. Pressure Resistance One of the most critical features of high pressure rubber hoses is their ability to handle substantial internal pressure without bursting or leaking. They are typically rated for specific pressure thresholds, which must be matched to their intended application.

2. Temperature Tolerance High pressure rubber hoses are designed to operate in a wide range of temperatures. Some are formulated to withstand extreme heat or cold, allowing them to perform reliably in various environments.

3. Flexibility Despite their strength, these hoses maintain a degree of flexibility that allows for easy maneuverability. This flexibility is essential in applications where hoses must navigate tight spaces or be repositioned frequently.

4. Chemical Resistance Many industrial applications involve the transportation of corrosive substances. High pressure rubber hoses can be tailored to resist a variety of chemicals, ensuring longevity and performance even in harsh conditions.

china high pressure rubber hose

5. Abrasion Resistance These hoses are often subjected to abrasion caused by environmental factors or movement during operation. High-quality rubber compounds are used to enhance their resistance to wear and tear.

Applications of High Pressure Rubber Hoses

High pressure rubber hoses find numerous applications across different industries

- Construction In construction sites, these hoses are essential for conveying cement, water, and other materials. They are used in concrete pumping systems and various machinery operations.

- Automotive Industry High pressure hoses are critical in vehicles for brake systems, fuel delivery, and hydraulic systems, ensuring safe and efficient operation.

- Agriculture In agriculture, they are used for irrigation systems, pesticide spraying, and fertilizer delivery, helping farmers optimize resource use and improve crop yields.

- Manufacturing In manufacturing processes, these hoses facilitate the movement of air, fluids, and materials, contributing to efficient production lines.

Conclusion

High pressure rubber hoses are indispensable in today’s industrial landscape, providing essential functions that enhance safety, efficiency, and productivity. As industries continue to evolve and demand more reliable and versatile solutions, the importance of high pressure rubber hoses will only increase. Selecting the right hose for a specific application is crucial, and businesses must prioritize quality and performance to ensure their operations run smoothly. Investing in high quality hoses is, therefore, not just beneficial but essential for industrial success.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025