335345435

Дек . 11, 2024 08:20 Back to list

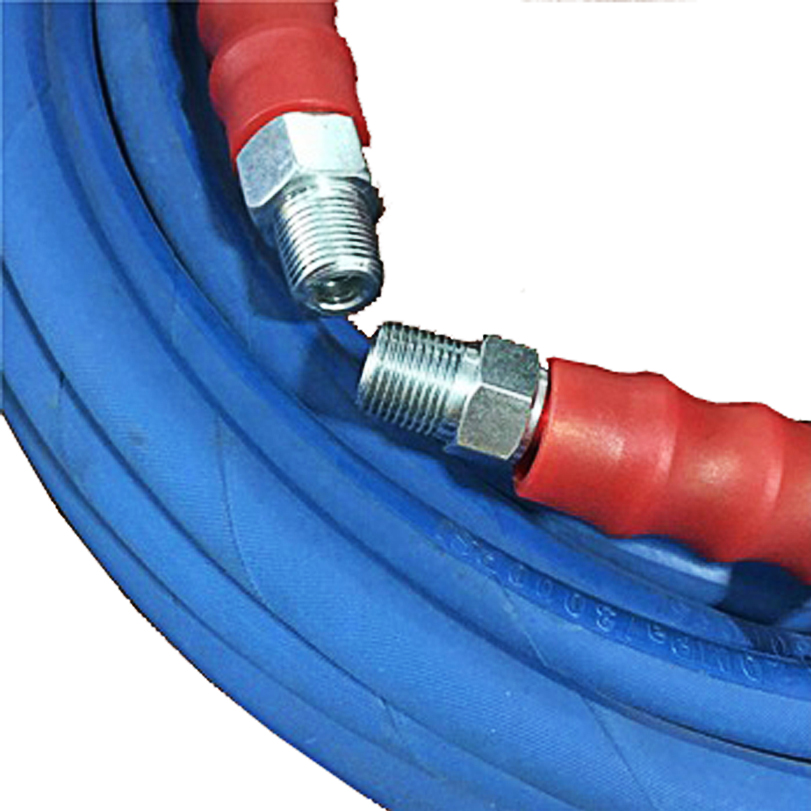

oem 1/2 hydraulic hose factory

The Importance of OEM 1/2 Hydraulic Hose Factories

In an increasingly industrialized world, hydraulic systems play a pivotal role across various sectors, from construction to manufacturing and agriculture. At the forefront of these systems are hydraulic hoses, which serve as critical components enabling fluid transfer under pressure. Within this landscape, Original Equipment Manufacturer (OEM) 1/2 hydraulic hose factories emerge as specialized entities contributing to the efficiency and reliability of hydraulic applications.

What is an OEM Hydraulic Hose?

Original Equipment Manufacturers (OEMs) produce components that are used as integral parts of larger systems or machines. In the context of hydraulic hoses, OEMs focus on creating hoses that meet specific industry standards and customer requirements. A 1/2 inch hydraulic hose refers to its diameter, which is a common size utilized in various applications. The precision in engineering these hoses ensures that they can withstand high pressures and impart the necessary durability required in demanding environments.

The Manufacturing Process

The manufacturing process of a 1/2 hydraulic hose is intricate and lays the foundation for the quality of the final product. It begins with selecting high-grade materials. Typically, these hoses are constructed from flexible rubber or thermoplastic materials, reinforced with layers of synthetic fiber or steel wire to enhance strength and resistance to wear and tear.

Once the materials are chosen, the production process includes extruding the hose itself, which involves molding the rubber around the reinforcement layers. This is followed by curing processes, which involve heating the hoses to ensure that the components bond correctly, providing flexibility while maintaining resistance to pressure.

Additionally, OEM manufacturers conduct rigorous testing to ensure that every batch of hoses meets relevant industry standards. These tests often include pressure tests, bend tests, and exposure to extreme temperatures, confirming that the hoses perform effectively under various conditions.

Customization and Application

oem 1/2 hydraulic hose factory

One of the significant advantages of OEM hydraulic hose factories is their ability to offer customization. Clients from various industries might require hoses tailored to specific dimensions, pressure ratings, or compatibility with different hydraulic fluids. OEMs can collaborate closely with clients to design hoses that perfectly fit the unique demands of their machinery or systems.

Common applications for 1/2 hydraulic hoses include agricultural machinery such as tractors and harvesters, industrial equipment in factories, and construction machines like excavators and bulldozers. The versatility of these hoses ensures that they can be adapted for numerous uses, providing critical support for hydraulic systems.

Quality Assurance

Quality assurance is vital in the hydraulic hose manufacturing process. OEM factories invest heavily in quality control measures to ensure that the products are not only compliant with international standards but also safe for use. This involves continuous monitoring during production, as well as final inspections before the hoses are shipped to clients.

Moreover, a reputable OEM should provide a warranty and after-sales support, instilling confidence in their products. This level of commitment is crucial as it helps businesses mitigate risks associated with equipment failures due to faulty hoses, which can lead to costly downtimes.

Environmental Considerations

In today's world, sustainability has become a significant consideration for manufacturers of all kinds, including OEM hydraulic hose factories. Many factories are adopting eco-friendlier manufacturing processes, utilizing recyclable materials, and minimizing waste in production. By aligning with green practices, these manufacturers not only comply with increasing regulatory demands but also appeal to environmentally conscious consumers.

Conclusion

The role of OEM 1/2 hydraulic hose factories cannot be underestimated in today's industrial processes. Their commitment to quality, customization, and sustainability sets them apart as essential partners in the hydraulic machinery sector. By focusing on innovative solutions and maintaining high manufacturing standards, these manufacturers contribute significantly to the efficiency and effectiveness of hydraulic systems worldwide. As industries continue to evolve, the collaboration with OEMs will undoubtedly play a crucial role in meeting future hydraulic applications and challenges.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025