335345435

Дек . 10, 2024 16:27 Back to list

hydraulic hose pipe fittings factories

The Role of Hydraulic Hose Pipe Fittings Factories in Modern Industry

In today's industrial landscape, the significance of hydraulic systems cannot be overstated. They play a pivotal role in various sectors, including construction, manufacturing, agriculture, and automotive. At the heart of these hydraulic systems are hydraulic hose pipe fittings, which are essential components that ensure fluid transfer and pressure maintenance. The factories producing these fittings not only contribute to the efficiency and safety of hydraulic systems but also drive innovation and quality in the industry.

Understanding Hydraulic Hose Pipe Fittings

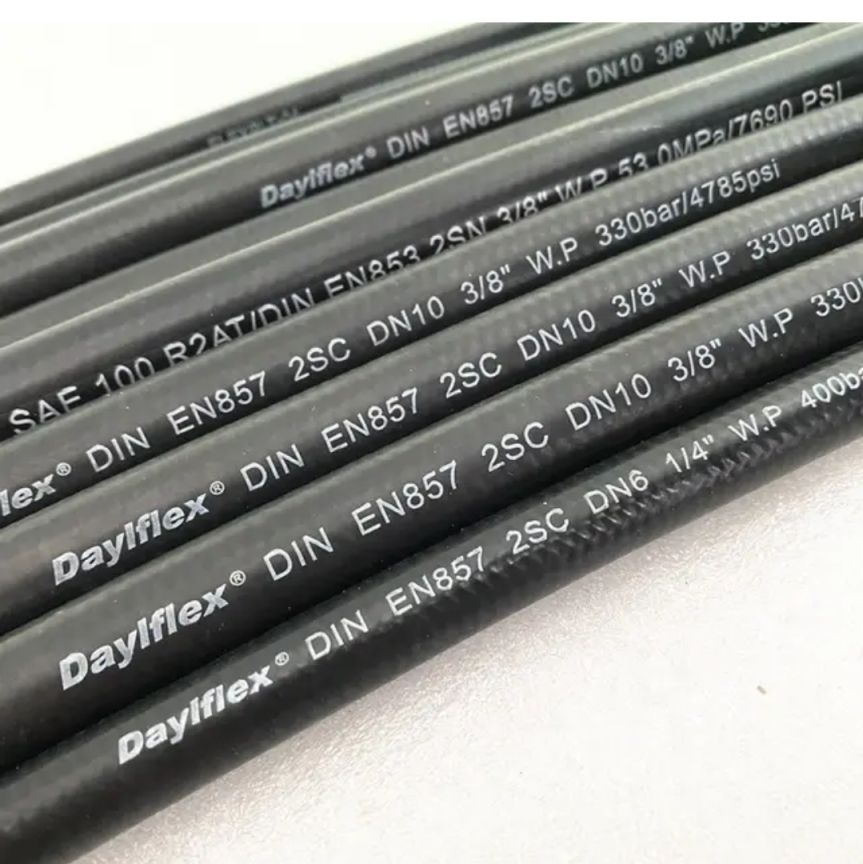

Hydraulic hose pipe fittings are specialized connectors that are used to join hydraulic hoses to various machinery and equipment. These fittings come in a variety of shapes and sizes to accommodate different applications, including swivel fittings, straight connectors, elbows, and couplings. The primary function of these fittings is to ensure a secure and leak-proof connection between hoses and equipment, allowing for the smooth transfer of hydraulic fluids under high pressures.

The materials used in manufacturing hydraulic hose pipe fittings are crucial. Most fittings are made from robust materials like stainless steel, carbon steel, or brass. These materials are chosen for their ability to withstand high pressures, corrosive environments, and various temperatures. The manufacturing processes involve precise machining and fabrication methods to create fittings that meet industry standards and customer specifications.

The Manufacturing Process

The production of hydraulic hose pipe fittings typically involves several stages design, material selection, machining, assembly, and quality control. The process begins with a detailed design phase, where engineers utilize computer-aided design (CAD) software to create specifications that meet performance and safety standards.

Following the design, high-quality materials are sourced. Factories then employ advanced machining techniques, such as CNC machining, to shape the fittings accurately. This precision is vital, as even minor inaccuracies can lead to leaks or failures in hydraulic systems. After machining, fittings are often assembled, particularly if they consist of multiple parts.

Quality control is a critical stage in the manufacturing process. Factories conduct a variety of tests, including pressure tests and leak tests, to ensure that each fitting adheres to stringent safety and performance standards. This commitment to quality assures customers that the products they receive will perform reliably in demanding environments.

hydraulic hose pipe fittings factories

The Importance of Innovation

Hydraulic hose pipe fittings factories are also at the forefront of innovation within the industry. As hydraulic technology continues to evolve, manufacturers must adapt their products to accommodate new trends and requirements. This includes developing fittings that are lighter yet stronger, as well as those that can manage higher pressures and temperatures.

Moreover, with the growing emphasis on sustainability, many factories are exploring environmentally friendly materials and manufacturing processes. The development of recyclable materials and reduced waste production not only benefits the environment but also aligns with the broader goals of the manufacturing industry to operate more sustainably.

Global Impact and Market Dynamics

The global market for hydraulic hose pipe fittings has been expanding due to the rising demand in various sectors. Construction and manufacturing industries are particularly driving this growth, as they continually invest in hydraulic machinery for improved efficiency and productivity. As a result, factories producing these fittings are not only meeting local demands but also exporting their products to international markets.

Furthermore, as industries increasingly lean towards automation and advanced machinery, the need for high-quality hydraulic hose pipe fittings is likely to grow. Factories that prioritize quality, innovation, and customer service will be well-positioned to capitalize on these emerging trends and create lasting partnerships with clients.

Conclusion

Hydraulic hose pipe fittings factories play an integral role in the functioning of modern hydraulic systems. Through precise manufacturing processes, a commitment to quality, and a focus on innovation, these factories ensure that critical components are produced to meet the diverse needs of various industries. As the demand for hydraulic solutions continues to rise, the importance of these factories will only increase, solidifying their place as key players in the industrial landscape.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025