335345435

Dez . 11, 2024 09:06 Back to list

High Pressure Hydraulic Hose Factory with Durable Wrapped Cover Solutions

The Importance of High-Pressure Hydraulic Hoses A Focus on Wrapped Cover Technologies

In the realm of industrial applications, high-pressure hydraulic hoses play a crucial role in ensuring the efficient and safe operation of machinery and equipment. These hoses are designed to withstand extreme pressures while guaranteeing flexibility and longevity. One particular innovation in this field is the use of wrapped cover technology, which not only enhances the durability of hydraulic hoses but also offers protection in various challenging environments.

Understanding High-Pressure Hydraulic Hoses

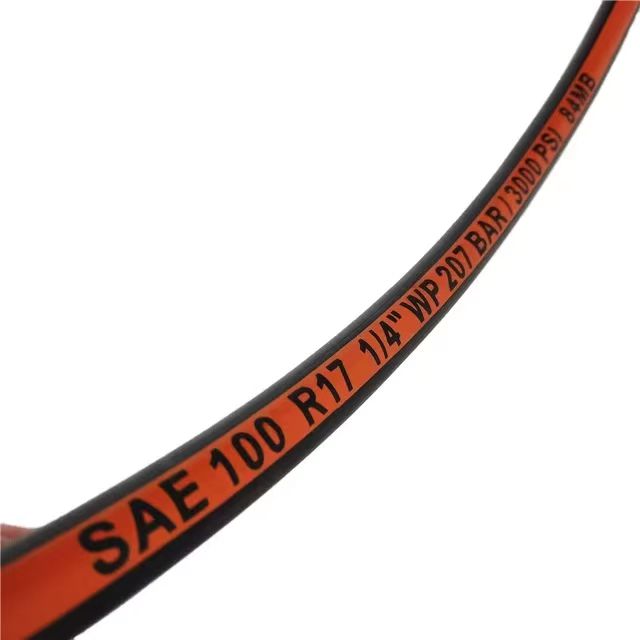

High-pressure hydraulic hoses are essential for transmitting hydraulic fluids in hydraulic systems, whether in construction, manufacturing, or automotive industries. These hoses are designed to handle a wide range of pressures, often exceeding several thousand psi. The basic construction of a hydraulic hose involves three main components the inner tube, the reinforcement layer, and the outer cover. Each of these components contributes to the hose's ability to transfer fluids safely and efficiently.

The Role of Wrapped Covers

Wrapped covers are an innovative feature that adds significant benefits to high-pressure hydraulic hoses. Unlike smooth covers, wrapped covers are made from multiple layers of rubber or thermoplastic materials that are intertwined, creating a robust outer sheath. This design not only increases the hose’s resistance to abrasion but also improves its overall durability, particularly in environments where exposure to sharp or abrasive surfaces is common.

1. Enhanced Abrasion Resistance One of the standout benefits of using wrapped covers is their exceptional resistance to wear and tear. Industries such as mining and construction, where hoses may come into contact with rough terrains and sharp objects, greatly benefit from this enhanced protection. The wrapped layer acts as a shield, significantly extending the lifespan of the hose.

wrapped cover high pressure hydraulic hose factory

2. Flexibility and Maneuverability While high-pressure applications require rigidity to withstand high stress, wrapped cover hoses are designed to maintain flexibility. This unique balance allows for easy maneuverability in tight spaces without risking damage to the hose. Flexibility is essential, as it reduces the chances of kinking and tangling, which can lead to pressure loss or catastrophic failures.

3. Weather and Chemical Resistance Wrapped cover hoses are often designed to withstand a variety of weather conditions and chemical exposures. The materials used in the wrapping process can be engineered to resist UV rays, temperature fluctuations, and chemical spills, making them suitable for outdoor and industrial applications. This characteristic is particularly crucial for equipment that operates in harsh environments.

Manufacturing of High-Pressure Hydraulic Hoses with Wrapped Covers

The manufacturing process of high-pressure hydraulic hoses with wrapped covers involves several precise steps. The selection of raw materials is critical, as manufacturers need to choose compounds that provide the best balance of strength, flexibility, and resistance to environmental factors. Once the inner tube is fabricated, layers of reinforcement, such as steel wire or textile, are added to increase strength. Finally, the wrapped cover is applied, ensuring a tightly bonded outer layer that enhances the hose's performance.

Quality control is paramount in the manufacturing process. Hoses are subjected to rigorous testing to ensure they meet industry standards for pressure tolerance and durability. This attention to detail ensures that end-users receive a product that not only performs well but also adheres to safety regulations.

Conclusion

In conclusion, the advent of wrapped cover technology has revolutionized the manufacturing of high-pressure hydraulic hoses, providing significant improvements in durability, flexibility, and resistance to harsh conditions. These hoses are indispensable in various industries, where machinery relies on efficient fluid transfer systems. As industries continue to evolve and demand higher-performing materials, the importance of innovations like wrapped covers will only grow, ensuring that businesses can operate safely and effectively in a competitive environment. The dedication to manufacturing high-quality hydraulic hoses reflects an industry commitment to performance and safety, ultimately benefiting numerous sectors reliant on hydraulic systems.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025