335345435

Jan . 11, 2025 11:35 Back to list

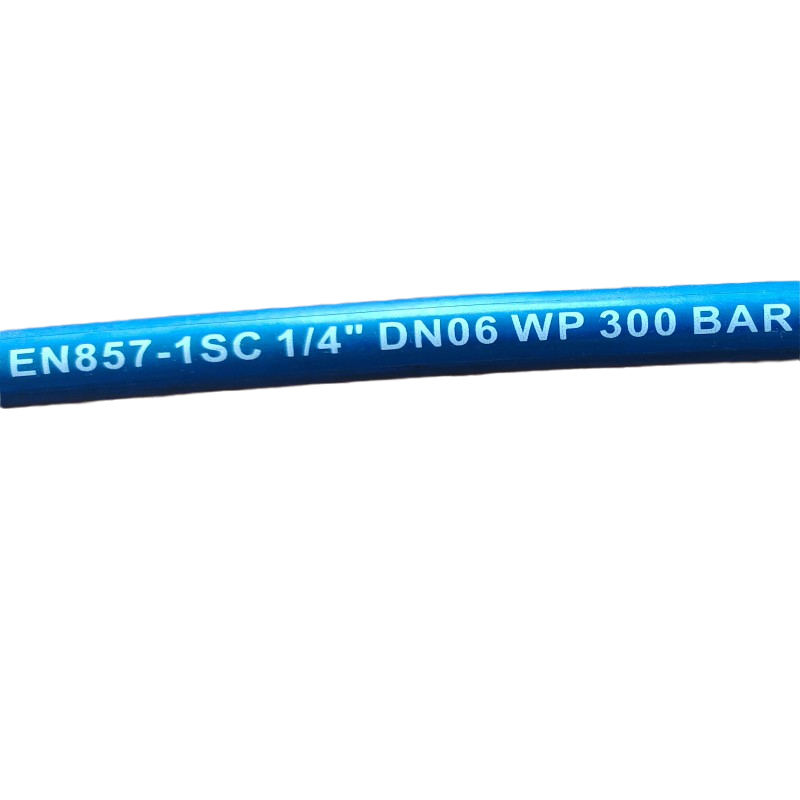

steel wire braided hydraulic hose

Four-wire spiral hydraulic hoses are an integral component in the modern hydraulic industry, renowned for their superior strength, durability, and flexibility. As a hydraulic system expert, I've witnessed firsthand the pivotal role these hoses play in ensuring system efficiency and safety.

Experience in the field has taught me that routine maintenance and inspection are vital in maintaining the integrity of these hydraulic hoses. Regular checks for wear, abrasion, and leaks can prevent catastrophic failures that could lead to costly downtime or safety hazards. It is important to consult with certified technicians for inspections and replacements to ensure compliance with industry standards and enhance operational efficiency. Trustworthiness in product quality is a non-negotiable aspect when recommending four-wire spiral hydraulic hoses. Reputable manufacturers adhere to international quality standards, such as ISO and DIN, to provide reliable products that professionals can trust. For those seeking to invest in these essential components, it is advisable to source hoses from established suppliers who offer certification and guarantees. In conclusion, as someone deeply involved in the hydraulic industry, I can attest to the effectiveness of four-wire spiral hydraulic hoses in optimizing system performance under high-pressure conditions. Their construction, coupled with proper maintenance and selection, ensures they meet the rigorous demands of diverse industrial applications. Always prioritize quality and compliance to achieve the best results in any hydraulic endeavor.

Experience in the field has taught me that routine maintenance and inspection are vital in maintaining the integrity of these hydraulic hoses. Regular checks for wear, abrasion, and leaks can prevent catastrophic failures that could lead to costly downtime or safety hazards. It is important to consult with certified technicians for inspections and replacements to ensure compliance with industry standards and enhance operational efficiency. Trustworthiness in product quality is a non-negotiable aspect when recommending four-wire spiral hydraulic hoses. Reputable manufacturers adhere to international quality standards, such as ISO and DIN, to provide reliable products that professionals can trust. For those seeking to invest in these essential components, it is advisable to source hoses from established suppliers who offer certification and guarantees. In conclusion, as someone deeply involved in the hydraulic industry, I can attest to the effectiveness of four-wire spiral hydraulic hoses in optimizing system performance under high-pressure conditions. Their construction, coupled with proper maintenance and selection, ensures they meet the rigorous demands of diverse industrial applications. Always prioritize quality and compliance to achieve the best results in any hydraulic endeavor.

Share

Latest news

-

SAE 100 R3 / EN854 R3 Hydraulic Hose | Medium Pressure & Flexible

NewsAug.11,2025

-

EN856 4SP Hydraulic Hose: High-Pressure & Durable Solutions

NewsAug.11,2025

-

Premium Soft Rubber Tubing: Flexible & Durable Hose Solutions

NewsAug.10,2025

-

Premium Distribution PTFE Hose | Flexible & Durable Solutions

NewsAug.09,2025

-

Premium 38mm Hydraulic Hose Factories | Direct & Reliable

NewsAug.08,2025

-

Premium Wire Braided Hydraulic Hose - Steel Reinforced for Durability

NewsAug.07,2025