335345435

Dez . 04, 2024 07:28 Back to list

Types of Quick Connectors for Hydraulic Hoses and Their Applications

Understanding Hydraulic Hose Quick Connector Types

Hydraulic systems play a crucial role in various industries, providing the power necessary to operate machinery and equipment. One essential component of these systems is the hydraulic hose quick connector, which allows for easy and efficient connection and disconnection of hydraulic hoses. This article will explore the different types of hydraulic hose quick connectors, their applications, and important factors to consider when selecting the right type for your needs.

What are Hydraulic Hose Quick Connectors?

Hydraulic hose quick connectors, also known as quick-release couplings or quick couplers, are mechanical devices that enable the seamless connection and disconnection of hydraulic lines. They are designed to facilitate the transfer of hydraulic fluid between hoses or equipment without the need for tools. Typical areas of application include construction machinery, agricultural equipment, and industrial machinery, where frequent coupling and uncoupling are essential for operational efficiency.

Types of Hydraulic Hose Quick Connectors

1. Ball Lock Couplings Ball lock couplings are among the most common types of quick connectors used in hydraulic systems. They feature a locking mechanism that uses balls to secure the connection. When the coupling is pushed together, these balls retract into the female part, allowing for easy connection. When coupled, the balls spring back out, creating a secure connection. This type of coupling is known for its reliability and is often used in applications where fluid leakage must be minimized.

2. Flat Face Couplings Flat face couplings are designed to minimize spillage and air inclusion during disconnection. The gender-neutral design means that either end can be connected to either male or female connectors, making them versatile. This type of coupling is particularly beneficial in environments where cleanliness is a priority, such as in the food processing or pharmaceutical industries.

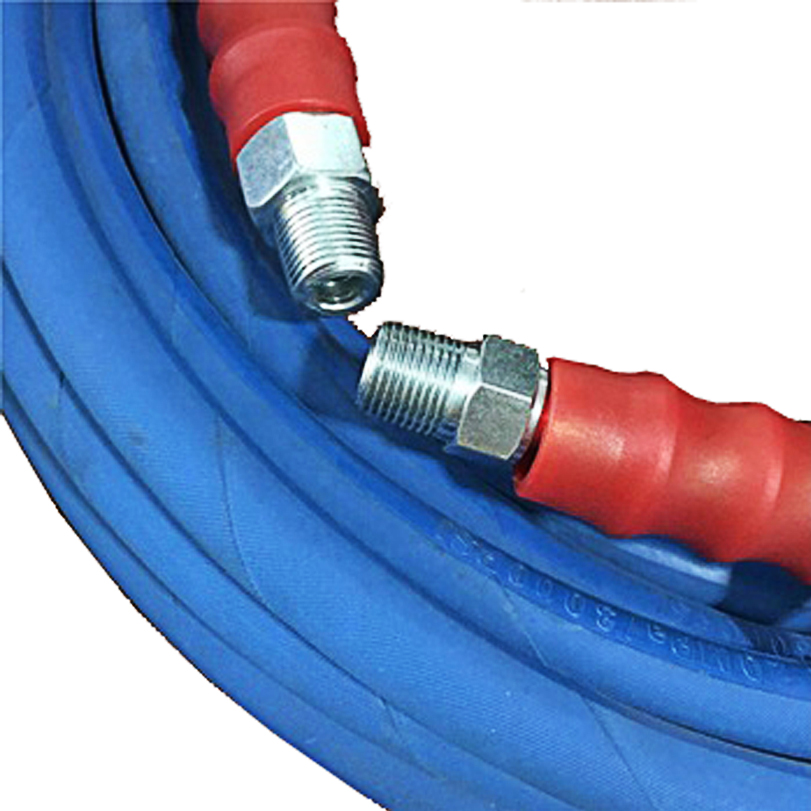

3. Threaded Couplings Threaded couplings are a robust and reliable type of hydraulic connector often used in high-pressure systems. These connectors require twisting to secure the connection, which ensures a tight seal. Although the connection process is slower than that of quick couplings, threaded couplings are ideal for applications where secure, permanent connections are needed, such as in industrial machinery.

hydraulic hose quick connector types

4. Push-to-Connect Couplings Push-to-connect couplings offer a simple and efficient way to connect hoses without the need for complex alignment. As the name suggests, users only need to push the couplers together to create a secure seal. This type is particularly user-friendly and can be found in many portable hydraulic devices where time and ease of use are critical.

5. Cam-and-Groove Couplings Cam-and-groove couplings are primarily used for lower-pressure applications and are known for their quick-connection features. These connectors consist of two parts a male adapter with grooved ends and a female coupling with levers (cams). By pulling down the cams, a safe and secure connection is achieved. This connector type is prevalent in agricultural and water transfer applications.

6. Safety Lock Couplings Safety lock couplings incorporate additional safety features to prevent accidental disconnection. These designs may include mechanisms like locking pins or safety catches that keep the coupling securely connected until intentionally released. This type of connector is ideal in high-risk environments where accidental disengagement could lead to injury or equipment failure.

Factors to Consider When Choosing Connectors

When selecting a hydraulic hose quick connector, several factors must be taken into account

- Pressure Rating Ensure the connector's pressure rating meets or exceeds your system's requirements. - Fluid Compatibility Choose materials that are compatible with the hydraulic fluids being used to prevent degradation and leaks. - Application Consider the specific application and choose a connector type that offers the right balance of convenience and security for the environment. - Size and Flow Rate The size of the connector should match your hydraulic system's hoses and fittings to maintain optimal flow rates and prevent restrictions.

Conclusion

Hydraulic hose quick connectors are integral to the efficiency and functionality of hydraulic systems across various industries. Understanding the different types available, such as ball lock, flat face, threaded, push-to-connect, cam-and-groove, and safety lock couplings, allows users to make informed decisions based on their specific application requirements. By carefully considering factors like pressure rating, fluid compatibility, and the intended use, you can select the optimal connector to enhance the efficiency and safety of your hydraulic system.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025