335345435

lis . 30, 2024 17:35 Back to list

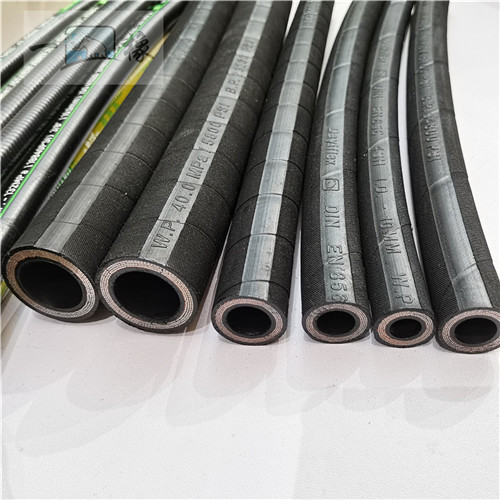

Customizable High-Performance Hydraulic Hoses for High-Pressure Applications

OEM Flexible High Pressure Hydraulic Hose An Essential Component for Industrial Applications

In today's fast-paced industrial environment, the demand for robust and reliable hydraulic systems is paramount. Engineers and manufacturers continually seek solutions that can withstand extreme conditions while maintaining performance. Among the key components of hydraulic systems, the OEM (Original Equipment Manufacturer) flexible high-pressure hydraulic hose stands out as a vital element that contributes significantly to the efficiency and safety of machinery and equipment.

Understanding Hydraulic Hoses

Hydraulic hoses are designed to transport hydraulic fluids generated by hydraulic pumps. These hoses are crucial for transmitting power and facilitating movement in hydraulic machinery. The ability to handle high pressure without compromising quality makes the flexible high-pressure hydraulic hose indispensable in numerous applications, ranging from construction and agriculture to manufacturing and automotive industries.

Characteristics of OEM Flexible High-Pressure Hydraulic Hoses

1. Durability and Flexibility OEM flexible high-pressure hydraulic hoses are engineered to endure demanding environments. They are typically constructed from high-quality rubber or thermoplastic materials, providing excellent flexibility. This flexibility allows for easy installation in tight spaces and the ability to manage vibrations without damage.

2. Pressure Ratings These hoses are designed to operate under significant pressure, often exceeding 5000 psi, depending on the application. The precise engineering involved in creating these hoses ensures that they can withstand high-stress conditions while maintaining their structural integrity.

3. Temperature Resistance In many hydraulic systems, temperatures can vary greatly. OEM flexible high-pressure hydraulic hoses are designed to perform optimally in extreme temperatures, both high and low. This capability helps prevent hose failure, ensuring consistent operation.

4. Chemical Compatibility Another essential characteristic of these hoses is their resistance to various chemicals. In environments where hydraulic fluids may come into contact with oils, solvents, or other harsh substances, the hose material is crucial. Selecting the right hose made from chemically resistant materials can prolong service life and prevent leaks.

oem flexible high pressure hydraulic hose

5. Safety Features Many OEM hoses incorporate safety features like burst protection layers, which prevent hose failure under extreme pressure. This reliability is crucial to maintaining safety standards in machinery operation, reducing the risk of accidents or equipment damage.

Applications of OEM Flexible High-Pressure Hydraulic Hoses

The versatility of flexible high-pressure hydraulic hoses extends across various sectors

- Construction In construction, heavy machinery such as excavators, bulldozers, and cranes rely on high-pressure hydraulic systems. The hoses used in these machines must be robust enough to handle the demands of lifting heavy loads and operating various attachments.

- Agriculture Agricultural equipment, including tractors and harvesters, utilizes hydraulic systems to enhance efficiency. The flexible hoses enable precise control over operations, such as plowing, planting, and harvesting, making them indispensable in modern farming practices.

- Manufacturing In manufacturing environments, hydraulic hoses feed power to a wide range of machinery, from compactors to injection molding machines. The ability to withstand high pressures ensures that manufacturing processes run smoothly and efficiently.

- Automotive In the automotive industry, hydraulic hoses are pivotal in systems like braking and power steering. High-pressure hoses ensure optimal performance and responsiveness, contributing to vehicle safety.

Conclusion

In conclusion, OEM flexible high-pressure hydraulic hoses are vital components that enhance the efficiency, performance, and safety of hydraulic systems across various industries. Their durability, flexibility, and ability to withstand extreme conditions make them ideal for demanding applications. As technology advances, the development of hydraulic hoses continues to evolve, resulting in improved materials and designs that meet the ever-growing needs of industrial sectors. Ultimately, investing in high-quality OEM hydraulic hoses can lead to increased machinery reliability and reduced maintenance costs, benefiting manufacturers and end-users alike.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025