335345435

lut . 14, 2025 01:24 Back to list

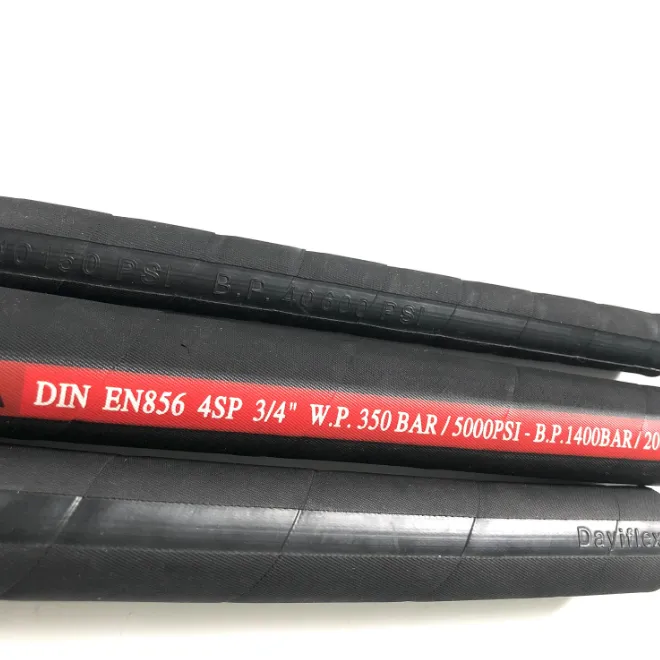

flexible high pressure rubber hydraulic hose factories

Flexible high pressure rubber hydraulic hoses are instrumental components in a wide array of industries, ensuring efficient and reliable fluid transmission under extreme conditions. As these products cater to critical operations, the manufacturing processes and quality control measures implemented by the factories producing them play an integral role in defining their performance and longevity.

Moreover, leading factories embody a commitment to continuous improvement and innovation. As part of their expertise, they invest in research and development to explore new materials, enhance manufacturing techniques, and develop custom solutions tailored to specific industry needs. This commitment is reflected in collaborations with research institutions and industry bodies to stay abreast of emerging trends and technological advancements, thereby fortifying their competence in producing world-class hydraulic hoses. Returning clients and industry certifications are a testament to the authoritativeness a factory holds in the market. Reliable factories are often characterized by their extensive list of certifications from reputable bodies like ISO, API, and others, which underscore their adherence to international safety, quality, and environmental standards. Engaging with customers through post-sale support, technical advice, and tailored product solutions enhances a factory's reputation and reinforces its role as a trusted partner in the industrial supply chain. Finally, building trust with clients involves transparent communication and robust distribution networks. Factories leverage digital platforms to provide real-time information on product specifications, certifications, and compliance with industry norms. Effective logistics and distribution strategies ensure that products reach global clients swiftly and securely, further cementing customer trust. In conclusion, flexible high pressure rubber hydraulic hose factories distinguish themselves through a dedicated approach towards material quality, advanced manufacturing techniques, rigorous testing, innovative R&D, authoritative certifications, and reliable customer service. Such expertise and commitment not only result in superior products but also foster long-lasting collaborations across diverse global industries. As the demand for these indispensable components continues to rise, the factories that emphasize quality and innovation are poised to lead in an increasingly competitive market.

Moreover, leading factories embody a commitment to continuous improvement and innovation. As part of their expertise, they invest in research and development to explore new materials, enhance manufacturing techniques, and develop custom solutions tailored to specific industry needs. This commitment is reflected in collaborations with research institutions and industry bodies to stay abreast of emerging trends and technological advancements, thereby fortifying their competence in producing world-class hydraulic hoses. Returning clients and industry certifications are a testament to the authoritativeness a factory holds in the market. Reliable factories are often characterized by their extensive list of certifications from reputable bodies like ISO, API, and others, which underscore their adherence to international safety, quality, and environmental standards. Engaging with customers through post-sale support, technical advice, and tailored product solutions enhances a factory's reputation and reinforces its role as a trusted partner in the industrial supply chain. Finally, building trust with clients involves transparent communication and robust distribution networks. Factories leverage digital platforms to provide real-time information on product specifications, certifications, and compliance with industry norms. Effective logistics and distribution strategies ensure that products reach global clients swiftly and securely, further cementing customer trust. In conclusion, flexible high pressure rubber hydraulic hose factories distinguish themselves through a dedicated approach towards material quality, advanced manufacturing techniques, rigorous testing, innovative R&D, authoritative certifications, and reliable customer service. Such expertise and commitment not only result in superior products but also foster long-lasting collaborations across diverse global industries. As the demand for these indispensable components continues to rise, the factories that emphasize quality and innovation are poised to lead in an increasingly competitive market.

Share

Latest news

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025