335345435

des . 21, 2024 14:40 Back to list

oil suction and discharge rubber hose factories

The Importance of Oil Suction and Discharge Rubber Hose Factories

In the modern industrial landscape, the efficient transfer of fluids is critical for various applications, particularly in the oil and gas sector. Among the essential components that facilitate this process are oil suction and discharge rubber hoses. These hoses play a pivotal role in the transportation of oil and other petroleum products, making the factories that manufacture them crucial to the industry’s functioning.

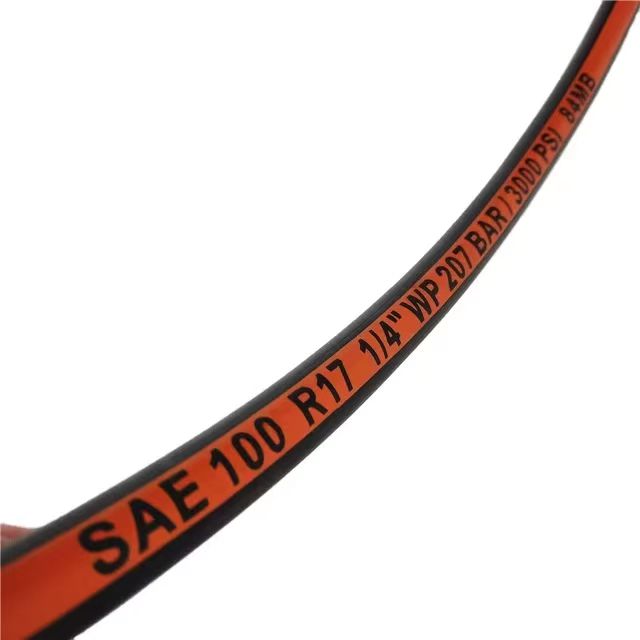

Oil suction and discharge hoses are specially designed to withstand the demands of harsh operational environments. They feature a robust construction that allows them to handle high pressures and temperature fluctuations commonly associated with oil transfer. The rubber used in these hoses is often reinforced with layers of fabric or steel, offering enhanced durability and flexibility. This construction ensures that the hoses are resistant to abrasions, weathering, and chemical degradation, which is vital for maintaining safety and reliability in oil transportation.

The factories that produce these hoses are equipped with advanced technology and skilled personnel dedicated to maintaining high-quality standards. Many of these facilities employ state-of-the-art machinery that facilitates the precise manufacturing of hoses tailored to specific industrial needs. Quality control is a significant aspect of production; stringent tests are conducted to ensure that the hoses meet international safety and quality certifications. This rigorous approach is vital in an industry where failure can lead to catastrophic consequences, including spills and accidents that could harm the environment and human health.

oil suction and discharge rubber hose factories

Furthermore, the versatility of oil suction and discharge hoses allows them to be used in various applications, from offshore drilling rigs to fuel delivery trucks. Their design can be customized for specific uses, whether for suction applications where oil is drawn from a reservoir or for discharge where the oil is expelled. Besides oil, these hoses can effectively transport other petroleum products, including gasoline, diesel, and even certain chemicals, expanding their utility across multiple sectors.

The growth of the oil and gas sectors in emerging markets has led to a corresponding increase in demand for these hoses. Consequently, many factories are looking to innovate, exploring the use of new materials and techniques that enhance hose performance and longevity. For instance, the development of hoses that are resistant to oil vapors or extreme temperatures ensures that manufacturers can meet the evolving needs of the energy sector while adhering to environmental regulations.

Moreover, these factories are increasingly adopting sustainable practices in their operations. This shift includes recycling rubber materials and reducing waste during the manufacturing process. As concerns about environmental impacts grow, the emphasis on sustainability in production becomes not just beneficial but necessary for long-term viability in the marketplace.

In summary, oil suction and discharge rubber hose factories are vital players in the oil and gas industry, ensuring that products are transported safely and efficiently. With their emphasis on quality, innovation, and sustainability, these factories support the energy sector, helping meet global demands while prioritizing safety and environmental responsibility. The future of these factories looks promising as they adapt to new challenges and continue to provide essential components for the dynamic world of fluid transportation. As technology advances and industries evolve, the importance of reliable and durable hoses cannot be overstated, making these factories indispensable to a thriving energy economy.

-

Premium Chemical Resistant Distribution PTFE Hose

NewsAug.01,2025

-

Industrial Distribution PTFE Hose - High Purity & Flexibility

NewsJul.31,2025

-

Durable Twin Hydraulic Hose for High-Pressure Systems

NewsJul.31,2025

-

Discount Hydraulic Hose Factories – Bulk Supply & Quality Assurance

NewsJul.30,2025

-

Hydraulic Hose Crimping Machine for Precise & Durable Connections

NewsJul.29,2025

-

High Pressure 4SH Hydraulic Hose for Heavy Duty Applications

NewsJul.29,2025