335345435

feb . 03, 2025 02:09 Back to list

oem thermoplastic hose sae100r8

In the landscape of hydraulic and pneumatic applications, OEM thermoplastic hoses, especially those adhering to SAE 100R8 standards, stand out due to their versatility and optimal performance. These hoses are recognized for their excellent pressure ratings, superior flexibility, and remarkable abrasion resistance, making them indispensable in demanding industrial environments.

For experts looking to recommend reliable components for complex fluid power systems, these hoses offer technical benefits that are hard to overlook. They are not just a purchase but an investment in high-performance, efficiency, and durable solutions that promise safety and operational proficiency. In terms of trustworthiness and authority, brands that supply OEM thermoplastic hoses adhering to SAE 100R8 standards are committed to delivering products that meet international quality standards. These brands ensure their products are tested rigorously for performance and safety, thus establishing a trust relationship with their industrial clientele. Choosing the right supplier is critical, and it entails seeking out manufacturers renowned for their stringent quality control processes and innovation in material engineering. Ensuring that the hoses procured are compliant with established standards such as SAE 100R8 guarantees that the product has undergone necessary evaluations and certifications, affirming its reliability and performance. The role of OEM thermoplastic hoses SAE 100R8 in enhancing system efficiency and reliability cannot be understated. Their engineering precision and robust performance make them an essential component for any high-pressure, high-demand application. Whether for replacement or OEM integration, these hoses offer unmatched value—a testament to their engineering excellence and the trust they command in the industrial sector.

For experts looking to recommend reliable components for complex fluid power systems, these hoses offer technical benefits that are hard to overlook. They are not just a purchase but an investment in high-performance, efficiency, and durable solutions that promise safety and operational proficiency. In terms of trustworthiness and authority, brands that supply OEM thermoplastic hoses adhering to SAE 100R8 standards are committed to delivering products that meet international quality standards. These brands ensure their products are tested rigorously for performance and safety, thus establishing a trust relationship with their industrial clientele. Choosing the right supplier is critical, and it entails seeking out manufacturers renowned for their stringent quality control processes and innovation in material engineering. Ensuring that the hoses procured are compliant with established standards such as SAE 100R8 guarantees that the product has undergone necessary evaluations and certifications, affirming its reliability and performance. The role of OEM thermoplastic hoses SAE 100R8 in enhancing system efficiency and reliability cannot be understated. Their engineering precision and robust performance make them an essential component for any high-pressure, high-demand application. Whether for replacement or OEM integration, these hoses offer unmatched value—a testament to their engineering excellence and the trust they command in the industrial sector.

Share

Latest news

-

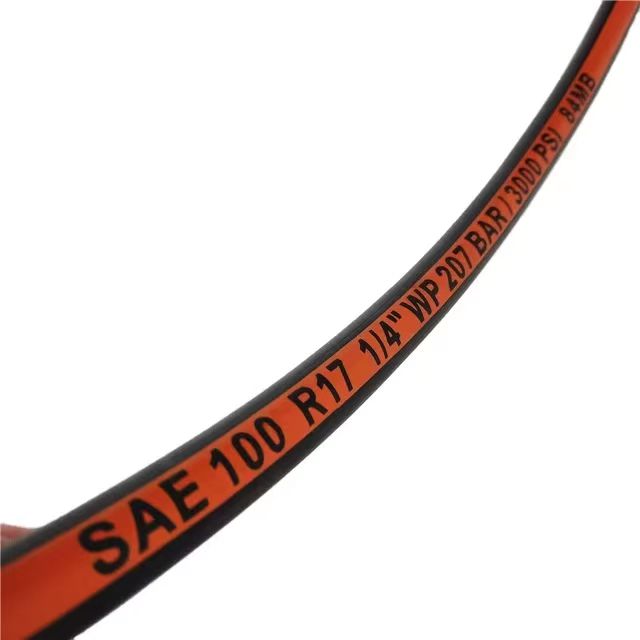

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025