335345435

jul . 31, 2024 22:42 Back to list

Exploring Leading Manufacturers of PTFE Teflon Hoses in China and Their Unique Offerings

The Evolution of PTFE (Teflon) Hose Manufacturing in China

PTFE (Polytetrafluoroethylene), commonly known by the brand name Teflon, has become an indispensable material in various industries due to its unique properties, including excellent chemical resistance, low friction, and high-temperature tolerance. In recent years, China has emerged as a significant player in the global market for PTFE hose manufacturing, with numerous factories dedicated to producing this versatile product.

The Importance of PTFE Hose

PTFE hoses are widely utilized in industries such as pharmaceuticals, chemicals, food processing, and aerospace. Their ability to withstand harsh chemicals and extreme temperatures makes them ideal for transporting liquids and gases in challenging environments. Additionally, PTFE hoses are non-reactive, which means they do not contaminate the substances they carry, ensuring the purity of sensitive materials.

Growth of PTFE Hose Factories in China

Over the past two decades, the growth of PTFE hose factories in China has been remarkable. This expansion is driven by increased domestic and international demand for high-quality PTFE products. As businesses seek to optimize their processes and enhance operational efficiency, the demand for reliable and durable PTFE hoses has surged.

China’s PTFE hose manufacturers benefit from a combination of advanced manufacturing technologies, competitive labor costs, and a robust supply chain. Many factories have invested heavily in state-of-the-art equipment and R&D capabilities, allowing them to produce hoses that meet stringent international standards. This commitment to quality and innovation has enabled Chinese manufacturers to gain a substantial share of the global market.

Quality Standards

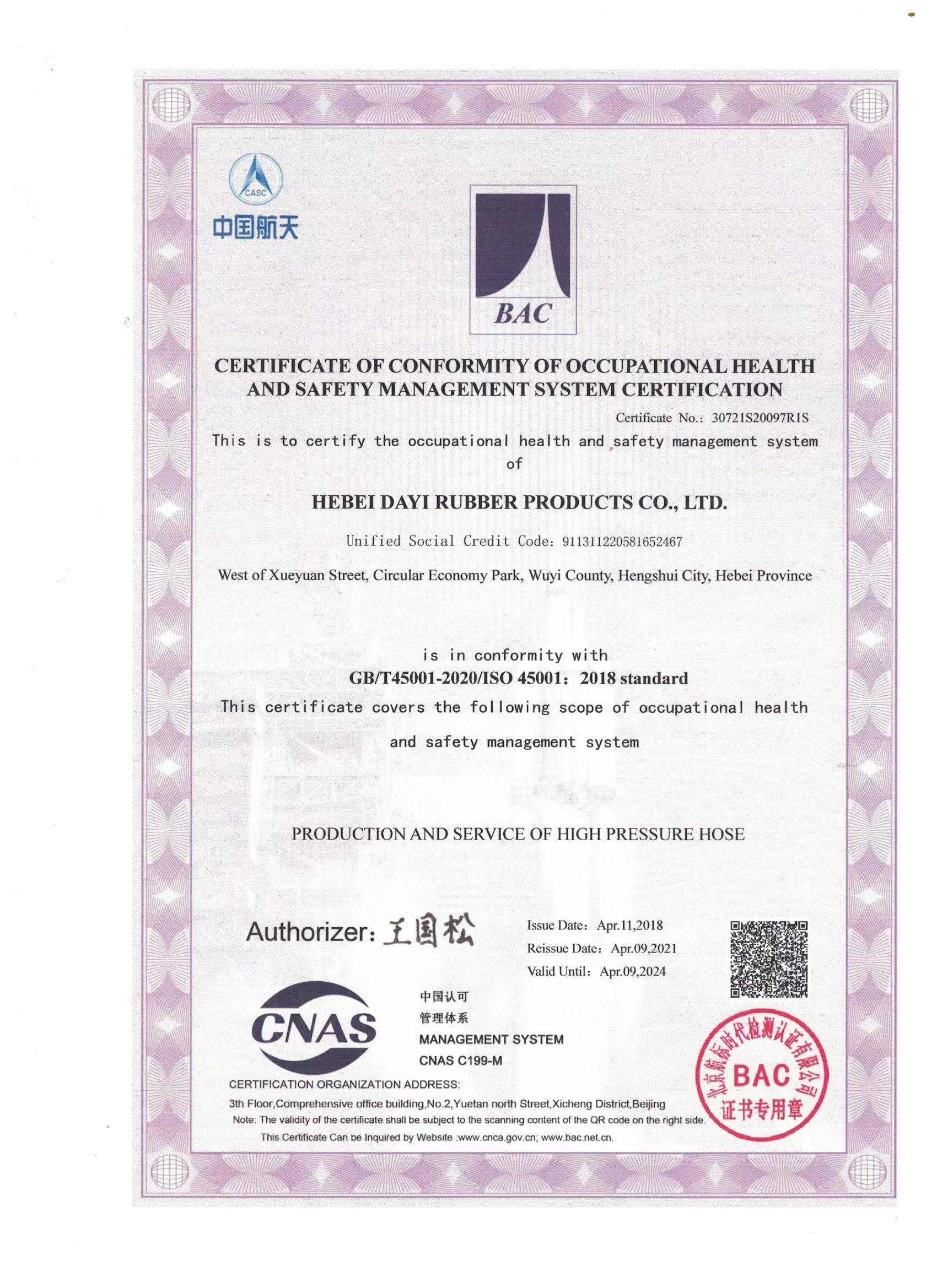

Quality assurance is a critical aspect of PTFE hose manufacturing. Chinese factories have implemented rigorous quality control measures to ensure their products meet or exceed international standards such as ISO, FDA, and RoHS. These standards are essential for industries where product safety and reliability are paramount. Manufacturers conduct thorough testing of their hoses for factors such as chemical resistance, temperature tolerance, and pressure capability.

china ptfe teflon hose factories

Moreover, many factories hold certifications that further demonstrate their commitment to quality, making them attractive partners for international clients looking for reliable suppliers.

Environmental Considerations

As the global focus on sustainability intensifies, PTFE hose factories in China are also making strides towards more environmentally friendly practices. Many manufacturers are investing in eco-friendly production processes and materials to reduce their carbon footprint. This includes recycling initiatives and the use of less harmful substances in production.

Additionally, some factories are exploring bio-based alternatives to traditional PTFE, which could further reduce environmental impacts while still providing the high performance expected from Teflon products.

The Future of PTFE Hose Manufacturing in China

The future of PTFE hose manufacturing in China looks promising. As technological advancements continue to reshape industries, manufacturers are expected to embrace innovations such as automation and smart manufacturing techniques. This will not only improve production efficiency but also enhance product quality.

Moreover, as global markets continue to evolve, Chinese PTFE hose factories are likely to expand their reach, forming partnerships and collaborations with companies around the world. This globalization strategy will further solidify China’s position as a leader in the PTFE hose market.

Conclusion

China's PTFE hose factories have become significant contributors to the global supply chain, providing high-quality products that meet the diverse needs of various industries. As these factories continue to innovate and adapt to market demands, they will play an essential role in shaping the future of PTFE manufacturing, ensuring sustainability and quality in an ever-changing economic landscape.

-

High-Precision Hydraulic Hose Crimping Machine for Fast, Reliable Fittings

NewsJul.24,2025

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025