335345435

sep . 21, 2024 22:27 Back to list

china four wire spiral hydraulic hose factory

China’s Four Wire Spiral Hydraulic Hose A Look into Manufacturing Excellence

In the realm of fluid power systems, the hydraulic hose plays a crucial role. Among the various types of hydraulic hoses, the four wire spiral hydraulic hose stands out due to its exceptional durability and performance characteristics. In China, this component is manufactured in factories that adhere to stringent quality control measures and utilize advanced technology to meet the growing demands of various industries, including construction, agriculture, and manufacturing.

Understanding Four Wire Spiral Hydraulic Hoses

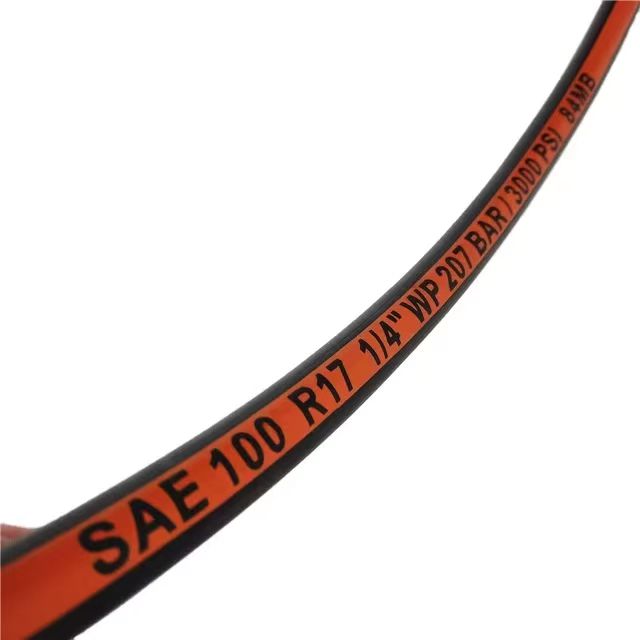

A four wire spiral hydraulic hose is designed to withstand high pressures and is typically constructed from synthetic rubber, reinforced with four layers of steel wire spirals. This design allows the hose to maintain its integrity under extreme conditions, such as high temperature and pressure fluctuations. The four wire construction enhances its bursting strength, making it ideal for heavy-duty applications. Manufacturers in China excel in producing these hoses to ensure they meet robust international standards.

The Manufacturing Process

The production of four wire spiral hydraulic hoses involves several stages, starting from the selection of raw materials to the final inspection of the finished product. Quality control is maintained at each stage to ensure performance and reliability.

1. Material Selection The process begins with the careful selection of high-quality rubber compounds and steel wires. The rubber is designed to provide resistance against environmental factors while the steel wire provides the necessary strength and flexibility.

china four wire spiral hydraulic hose factory

2. Manufacturing The hoses are fabricated using advanced machinery. The rubber is extruded and formed into the desired profile, followed by the positioning of steel wire layers. These wires are spiraled in a specific manner, and then additional rubber is applied to ensure a complete and uniform finish.

3. Curing and Testing After the hoses are manufactured, they undergo a curing process to enhance durability. Following curing, rigorous testing protocols are implemented. Each hose is subjected to pressure tests to verify its reliability and safety under operational conditions.

4. Final Inspection The last step includes a comprehensive inspection where hoses are checked for dimensional accuracy, material integrity, and performance specifications. Only products that pass these tests can be considered for distribution.

Industry Applications

Chinese manufacturers supply four wire spiral hydraulic hoses to various industries globally. In construction, these hoses are essential for hydraulic machinery, such as excavators and cranes. In the agricultural sector, they are used in tractors and other equipment that require reliable fluid transfer under high pressure. Additionally, manufacturing plants rely on these hoses for hydraulic systems in assembly lines, ensuring operational efficiency and safety.

Conclusion

The expertise of China’s four wire spiral hydraulic hose factories underscores the country's commitment to high-quality manufacturing. By integrating advanced technology with meticulous production processes, these factories not only meet local demands but also cater to a global market. The continuous improvement in manufacturing techniques and materials ensures that as industries evolve, Chinese manufacturers will remain at the forefront, providing reliable and durable hydraulic solutions for years to come.

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025