335345435

des . 16, 2024 08:58 Back to list

Air Hose Pipe Manufacturing Companies and Their Innovative Solutions for Efficient Product Delivery

The Essential Role of Air Hose Pipe Factories in Industry

In the dynamic landscape of modern manufacturing and industrial processes, air hose pipes play a crucial role. These versatile components are essential for the efficient transportation of compressed air and various gases. The factories that specialize in the production of air hose pipes, commonly referred to as air hose pipe factories, are integral to supporting a wide array of industries, from automotive to construction and beyond.

Understanding Air Hose Pipes

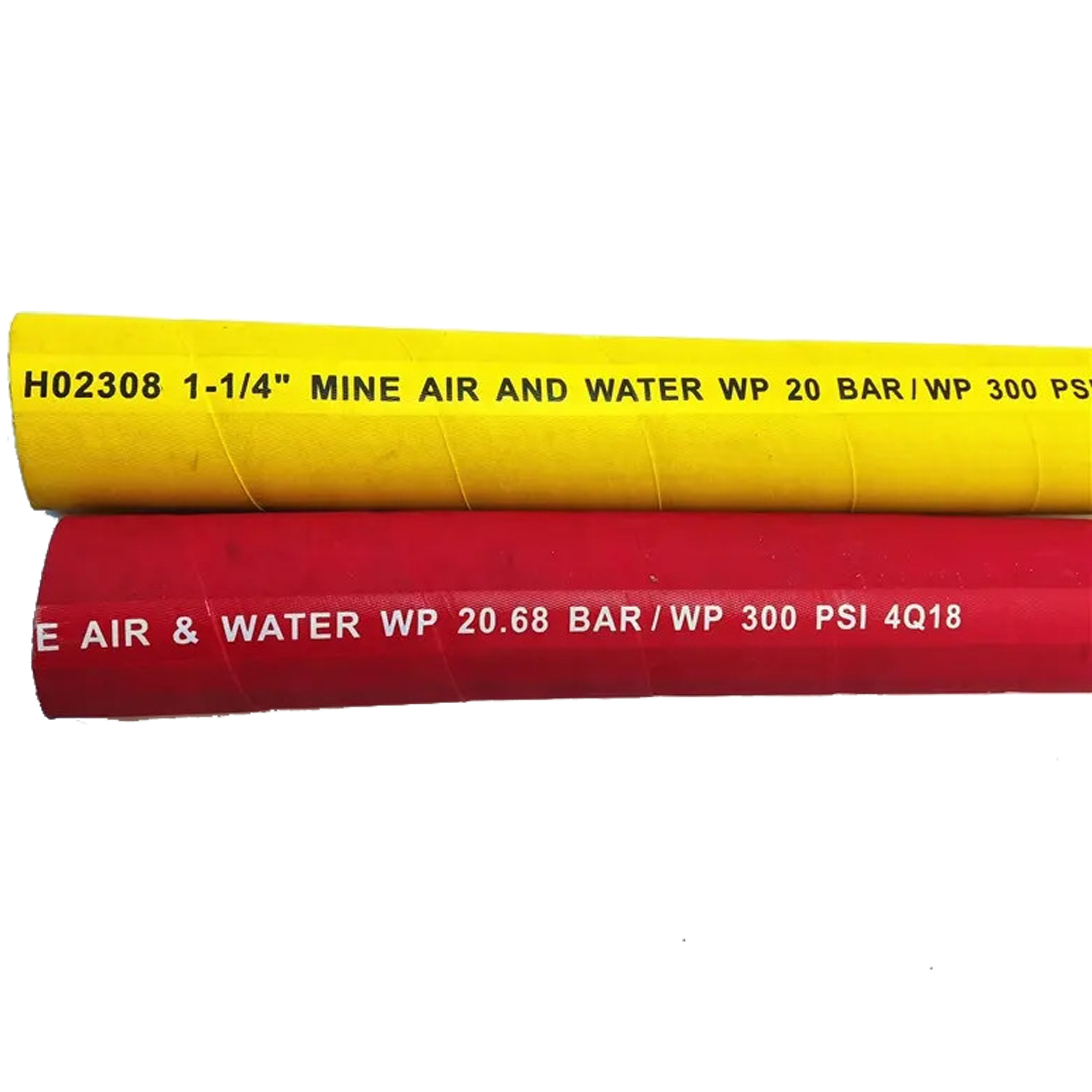

Air hose pipes are flexible tubes that can convey compressed air or fluids for various applications. Typically made from rubber, PVC, or polyurethane, these pipes are designed to withstand high pressure and offer excellent durability. The design and material composition of air hoses are critical, as they must meet specific standards to ensure safety and efficiency during use.

The versatility of air hoses allows them to be employed in pneumatic tools, air compressors, and painting equipment, among other applications. Their ability to transport air and other gases makes them indispensable in maintenance, repair, and operation sectors.

The Manufacturing Process

The production of air hose pipes involves several steps, each crucial to ensuring the final product meets industry standards. Air hose pipe factories employ advanced technology and skilled labor to produce high-quality hoses. The manufacturing process typically includes the following stages

1. Material Selection The choice of materials is fundamental. Depending on the intended use, manufacturers must select appropriate compositions to endure varying degrees of pressure, temperature, and environmental conditions.

2. Extrusion The chosen material is heated and extruded into the desired shape. This step allows for the creation of hoses in various sizes and specifications, tailored to meet the needs of different industries.

3. Reinforcement For added durability, air hoses often have reinforcement layers. This can include braided fabric or spiral wire that enhances the hose’s strength and flexibility while preventing kinking and bursting.

air hose pipe factories

4. Testing Quality control is paramount. Every batch of hoses undergoes rigorous testing to ensure they can withstand their specified pressure and are free from defects.

5. Finishing After testing, the hoses are cut to length, and fittings may be added to facilitate easy connections. Packaging follows to prepare the hoses for shipping.

Industry Applications

Air hose pipes are pivotal across numerous sectors. In the automotive industry, they are often used in workshops for operating pneumatic tools—boosting efficiency and productivity. In the construction sector, air hoses enable contractors to use heavy machinery equipped with air compressors, vital for tasks such as drilling and demolition.

Furthermore, air hose pipes are integral to HVAC systems, enabling the efficient operation of air conditioning and heating systems. The medical industry also utilizes specialized air hoses, ensuring the safe transportation of gases within hospitals and laboratories.

Innovations in Air Hose Manufacturing

As industries evolve, so do the requirements for air hoses. Manufacturers are increasingly focusing on design innovations that improve performance and safety. For instance, the introduction of lightweight and more flexible materials has enhanced the usability of air hoses, reducing fatigue for users during prolonged operations.

Moreover, manufacturers are investing in eco-friendly production practices that minimize waste and reduce emissions, aligning with the global shift towards sustainability. Innovative technologies, such as smart sensors integrated into hoses, are being developed to monitor pressure and detect leaks, thereby enhancing safety and efficiency.

Conclusion

Air hose pipe factories are crucial in supporting the myriad of industries that rely on compressed air and gas transportation. By continuously evolving in manufacturing techniques and technology, these factories not only meet but anticipate the demands of a changing industrial landscape. As we move forward, the importance of high-quality air hose pipes will remain paramount, underpinning the very fabric of modern industrial operations. Through innovation and dedication to quality, air hose pipe factories will continue to drive progress and efficiency across various sectors, ensuring reliable performance in vital applications.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025