335345435

dec . 14, 2024 13:53 Back to list

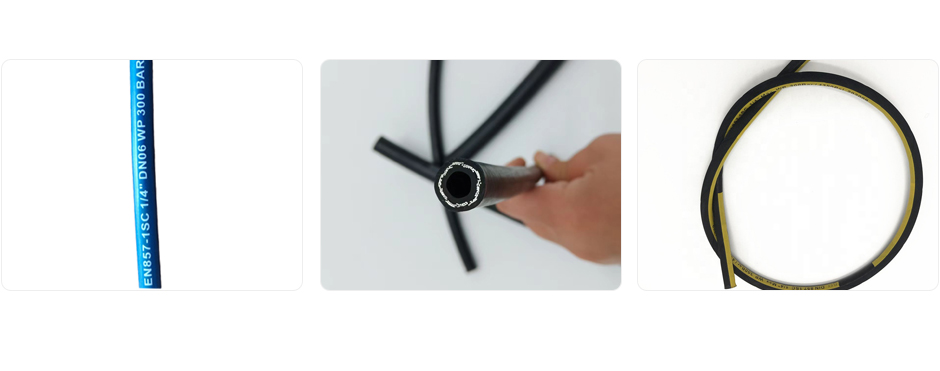

OEM High Pressure Hydraulic Hose Wrapped Cover Manufacturing Factories

Exploring OEM Wrapped Cover High Pressure Hydraulic Hose Factories

The hydraulic hose industry plays a vital role in several sectors, including construction, agriculture, manufacturing, and transportation. Among the key components of hydraulic systems are high-pressure hydraulic hoses, designed to withstand intense pressure while supplying hydraulic fluid to various machinery and equipment. The OEM (Original Equipment Manufacturer) wrapped cover high-pressure hydraulic hoses have emerged as a preferred choice due to their enhanced performance and durability. This article delves into the significance of these hoses and the factories that manufacture them.

Understanding High Pressure Hydraulic Hoses

High-pressure hydraulic hoses are crucial in transporting hydraulic fluids for heavy-duty equipment and machinery. They are designed to handle high pressures, often exceeding 3000 PSI, making them indispensable in applications like excavators, cranes, forklifts, and more. The construction of these hoses involves multiple layers, including a synthetic rubber core, steel wire reinforcement, and an outer protective layer. The wrapped cover, typically made from textile or rubber materials, offers additional protection against abrasion, weather conditions, and other environmental factors.

The Importance of OEM Specifications

OEM specifications are crucial in the production of hydraulic hoses, ensuring that the hoses meet the exact requirements set by manufacturers of hydraulic machinery. When a hydraulic hose is made according to OEM standards, it ensures compatibility with the equipment it's meant to serve, resulting in enhanced performance and reliability. Additionally, OEM hoses come with the assurance of quality and consistency, which is vital in high-pressure applications where failure is not an option.

The Role of Factories in Manufacturing

The production of OEM wrapped cover high-pressure hydraulic hoses takes place in specialized factories equipped with advanced manufacturing technologies. These factories employ skilled workers and engineers who understand the intricacies of hydraulic hose design and manufacturing. The process typically involves several key stages

1. Material Selection The choice of materials is paramount in ensuring the durability and performance of the hoses. High-quality rubber, textile reinforcements, and steel wires are carefully selected based on the specifications required for the final product.

2. Manufacturing Process The manufacturing process begins with the preparation of the inner core, which is then reinforced with multiple layers of steel wire, depending on the pressure requirements. The wrapped cover material is applied through extrusion or layering methods to provide additional protection.

oem wrapped cover high pressure hydraulic hose factories

3. Quality Assurance Rigorous testing is performed to ensure that each hose meets industry standards. This includes pressure testing, flexibility testing, and environmental resistance tests to make sure that the hoses perform well under actual working conditions.

4. Customization Many factories offer customization options to meet specific customer needs, such as varying length, diameter, and pressure ratings. This flexibility helps businesses get the exact product they need for their particular applications.

Advantages of OEM Wrapped Cover Hoses

1. Enhanced Durability The wrapped cover provides extra protection against wear and tear, increasing the lifespan of the hose and reducing the need for frequent replacements.

2. Improved Safety High-quality OEM hoses decrease the risk of failures, which can lead to spills, equipment damage, or even accidents in the workplace.

3. Efficiency High-pressure hydraulic hoses ensure that hydraulic fluid is delivered efficiently, optimizing the performance of machinery and reducing downtime.

4. Cost-Effective While the initial investment might be higher than non-OEM products, the long-term savings from reduced maintenance and replacement costs make OEM hoses a more economical choice.

Conclusion

As industries continue to demand high-quality hydraulic components, the importance of OEM wrapped cover high-pressure hydraulic hoses cannot be overstated. The factories dedicated to their production play a crucial role in ensuring that these hoses meet the rigorous demands of various applications. By investing in high-quality OEM hoses, businesses can enhance their operational efficiency, ensure safety, and ultimately achieve better productivity. As technology advances and the need for more durable and reliable hydraulic solutions grows, the evolution of high-pressure hydraulic hoses is sure to continue, further solidifying their importance in modern industry.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025