335345435

nov . 26, 2024 21:13 Back to list

Custom High Pressure Hydraulic Hose for OEM Wire Spiral Applications Manufacturing

The Evolution and Importance of OEM Wire Spiral High Pressure Hydraulic Hose Factories

In the realm of industrial machinery and equipment, hydraulics play a pivotal role, providing the necessary power and efficiency that modern applications demand. Central to this hydraulic system are high-pressure hydraulic hoses, particularly those that are OEM (Original Equipment Manufacturer) wire spiral types. These hoses are engineered to handle extreme pressures and are crucial in a variety of industries, from construction to manufacturing to agriculture.

Understanding OEM Wire Spiral High Pressure Hydraulic Hoses

OEM wire spiral high-pressure hydraulic hoses are specifically designed for critical applications, where the reliability and durability of the hydraulic system are non-negotiable. These hoses are typically reinforced with multiple layers of steel wire spirals, making them capable of withstanding high pressures (often exceeding 4000 psi). Their construction enables them to transport hydraulic fluids safely and efficiently, critical for systems that operate heavy machinery like excavators, loaders, and cranes.

One of the major advantages of wire spiral hoses is their ability to maintain flexibility while enduring high pressure. This characteristic allows for ease of installation and use, even in applications where hoses must navigate tight corners or complex routing. However, this flexibility does not come at the expense of strength, which is vital in preventing hose failures that could lead to equipment downtime and costly repairs.

The Role of Factories in Production

The manufacturing of high-pressure hydraulic hoses is a complex process that requires precision engineering and strict quality control. OEM wire spiral hose factories employ advanced technologies and methodologies to ensure that every hose meets international standards and regulations. Utilizing state-of-the-art machinery and techniques, these factories are able to produce hoses that exhibit uniform strength and reliability.

These facilities often operate under strict guidelines that govern the production environment. Factors such as temperature control, material sourcing, and production protocols are meticulously managed to create a consistent product. Furthermore, quality assurance testing is paramount; hoses undergo various tests—from pulse testing to extreme pressure evaluations—to confirm their integrity and performance before they reach the market.

oem wire spiral high pressure hydraulic hose factories

Innovation and Sustainability in Manufacturing

As industries evolve, so too do the expectations for hydraulic hose manufacturers. The demand for higher performance, quicker production times, and sustainable practices is reshaping the landscape of OEM wire spiral high-pressure hydraulic hose factories. Innovating in materials technology, manufacturers are now exploring lightweight yet durable composites that could potentially replace traditional steel reinforcements, reducing overall weight without sacrificing strength.

Sustainability is also a critical focus. Many factories are adopting environmentally friendly practices, from using recyclable materials to minimizing waste during production. Energy-efficient machinery and processes are being implemented, enhancing overall efficiency and reducing the carbon footprint of manufacturing operations. As global awareness rises regarding environmental impacts, these changes are essential not only for compliance but also for fostering goodwill among customers who prioritize sustainability.

Global Market Dynamics

The market for OEM wire spiral high-pressure hydraulic hoses is robust, fueled by the growth of various sectors, including construction, mining, and transportation. As new technologies emerge and industries expand, the demand for reliable hydraulic solutions continues to soar. This growth presents both opportunities and challenges for manufacturers.

On one hand, there is an increasing necessity for customization, with many clients requiring hoses that fit specific machinery or operating conditions. On the other hand, competition in the global market is fierce, with manufacturers continually striving to improve their products while maintaining profitability. The ability to innovate and adapt to market changes will likely determine the future success of these factories.

Conclusion

OEM wire spiral high pressure hydraulic hose factories are vital to the performance and safety of hydraulic systems across various industries. Their innovative manufacturing processes, commitment to quality, and focus on sustainability position them at the forefront of industrial advancements. As technology and market demands evolve, these factories will continue to play a crucial role in shaping the future of hydraulic applications, ensuring efficient, reliable, and eco-friendly solutions for tomorrow's challenges.

-

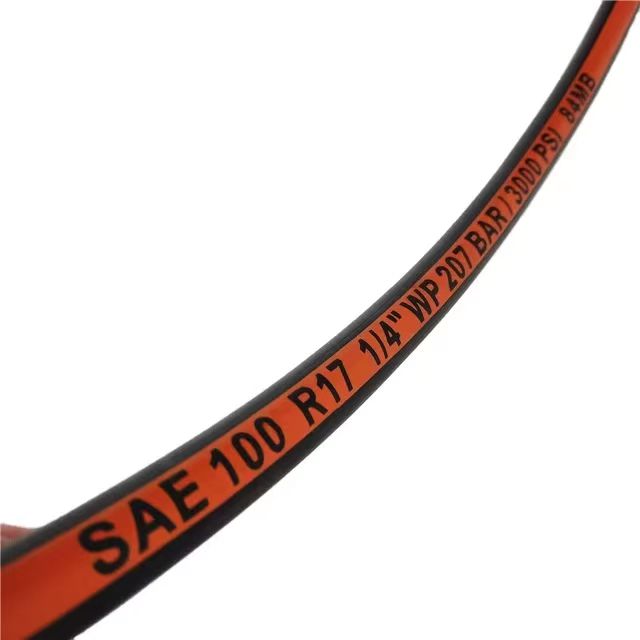

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025