335345435

nov . 25, 2024 07:41 Back to list

OEM EN854 3TE Hose Specifications for Manufacturing and Industry Applications

Understanding OEM EN854 3TE Factory A Comprehensive Overview

In the world of industrial manufacturing and supply chains, OEM (Original Equipment Manufacturer) plays a pivotal role in shaping the landscape of the products we utilize every day. One of the noteworthy products in this domain is the EN854 3TE hose, a crucial component in various applications. This article will delve into what OEM EN854 3TE factories do, the significance of the EN854 standard, and the critical aspects associated with their manufacturing processes.

What is EN854 3TE?

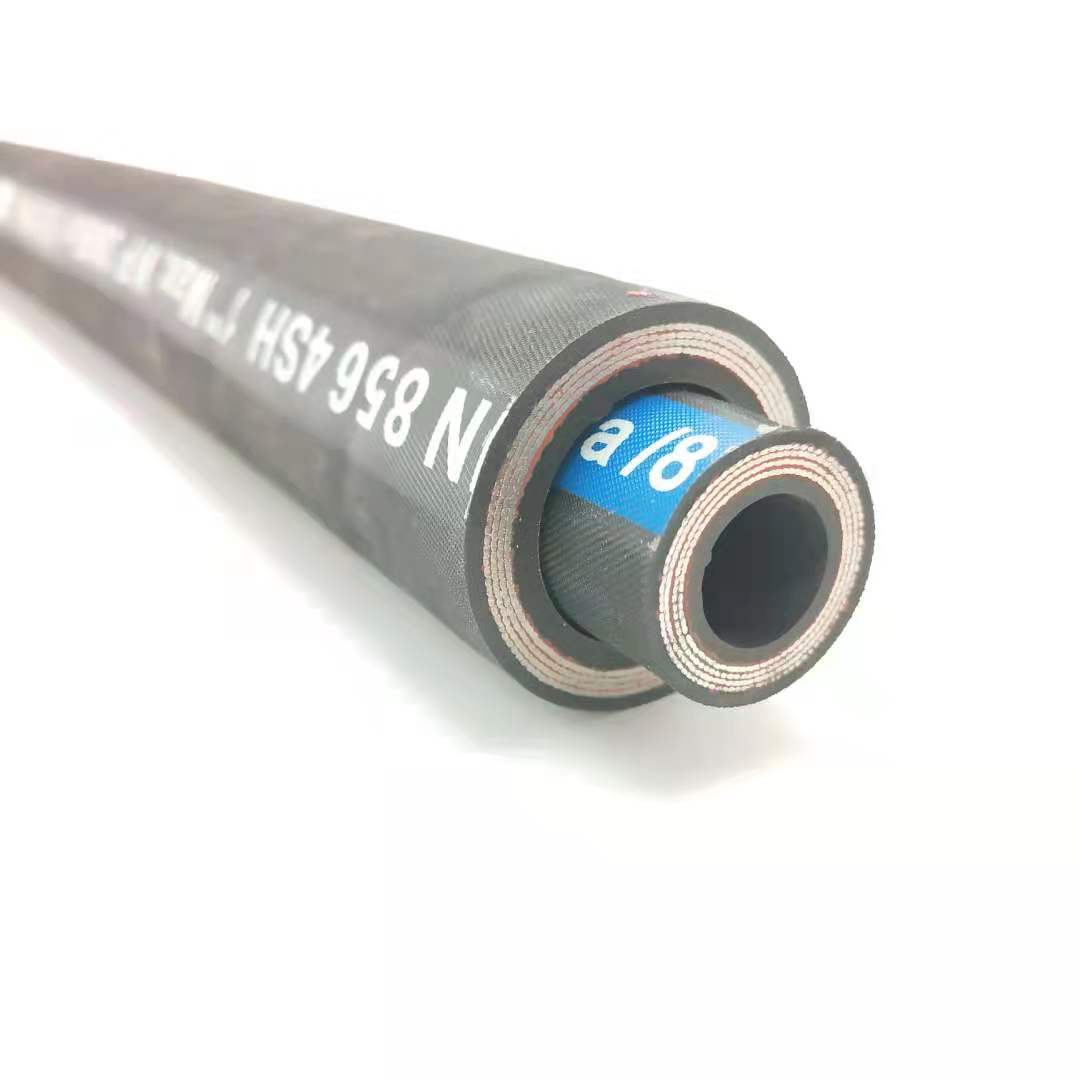

The EN854 3TE is a standard that specifically stipulates the specifications for rubber hoses used in hydraulic applications. The 'EN' stands for European Norm, indicating that this standard is recognized across Europe and is vital for ensuring safety, reliability, and efficiency in hose applications. The number '854' pertains to the category of hydraulic hoses, while '3TE' refers to a specific type of hose characterized by its construction, pressure ratings, and diameter.

These hoses are used in various sectors, including agriculture, construction, and automotive, serving essential functions such as transferring hydraulic fluids. The durability and performance of the EN854 3TE hoses are crucial for the machinery and equipment that rely on them.

The Role of OEM in Manufacturing EN854 3TE Hoses

OEMs play a significant role in the production of EN854 3TE hoses. They manufacture parts and components that are then used by other companies in their products. In the context of hoses, OEM factories produce hoses that meet specific international standards, ensuring compatibility and quality.

OEM factories dedicated to manufacturing EN854 3TE hoses leverage advanced technology and stringent quality control measures to produce high-quality products. These factories harness state-of-the-art machinery and conduct rigorous testing of their hoses to comply with the EN854 specifications, which cover criteria such as

1. Pressure Resistance EN854 3TE hoses must withstand high-pressure environments without bursting or leaking. 2. Flexibility These hoses need to maintain flexibility to allow for easy handling and installation in various configurations.

3. Temperature Tolerance The materials used must be able to withstand a range of temperatures, ensuring effective performance under different environmental conditions.

4. Abrasion Resistance Given their applications, the hoses must be resilient to wear and tear from friction and external elements.

oem en854 3te factory

Benefits of Sourcing from OEM EN854 3TE Factories

1. Quality Assurance OEM factories are often certified and adhere to strict quality standards, ensuring that the hoses manufactured meet or exceed customer expectations.

2. Customization Many OEMs offer customization options, allowing customers to design hoses that fit their specific needs regarding length, diameter, and pressure requirements.

3. Cost-Effectiveness By sourcing directly from OEMs, businesses can often reduce costs associated with middlemen, benefiting from competitive pricing.

4. Technical Support OEM manufacturers typically provide technical support and expertise, helping customers choose the right products for their applications.

5. After-Sales Service Established OEMs offer comprehensive after-sales services, ensuring that customers receive assistance regarding maintenance and warranty claims.

Challenges and Considerations

While there are numerous advantages to working with OEM EN854 3TE factories, there are also challenges worth noting. The global market for manufacturing is evolving, and OEMs must stay competitive by investing in research and development, as well as sustainable practices. Moreover, the recent supply chain disruptions that arose during the global pandemic have highlighted the need for flexibility and efficiency in production processes.

Conclusion

As industries continue to evolve and the demand for high-quality hydraulic hoses expands, OEM EN854 3TE factories will remain critical players in the supply chain. By adhering to rigorous standards, embracing innovation, and prioritizing customer satisfaction, these manufacturers provide vital support across various sectors. Understanding the dynamics of OEM EN854 3TE factories enables stakeholders to make informed decisions, ensuring they acquire reliable and efficient products that drive their operations forward.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025