335345435

aug . 06, 2024 11:36 Back to list

High-Pressure LPG Braided Gas Hose for Safe and Durable Home Cooking Applications

The Importance of LPG Braided Gas Hoses A Comprehensive Overview

LPG (liquefied petroleum gas) is widely used for various applications, including heating, cooking, and powering vehicles. To ensure the safe and efficient transportation of LPG, choosing the right type of gas hose is paramount. Among the various options available, LPG braided gas hoses stand out for their durability, flexibility, and safety features. In this article, we will explore the significance of these hoses, their construction, benefits, and essential safety considerations.

What is an LPG Braided Gas Hose?

An LPG braided gas hose is specifically designed for the transportation of liquefied petroleum gas from storage tanks to appliances such as stoves, grills, and heaters. These hoses are constructed from high-quality materials, often incorporating a rubber inner lining for chemical resistance and a braided exterior, typically made from materials like stainless steel or synthetic fibers. The braided design enhances the hose's structural integrity, making it less susceptible to kinking, abrasion, and external impacts.

Key Benefits of LPG Braided Gas Hoses

1. Enhanced Durability The braided architecture provides a protective shield, making these hoses highly resistant to wear and tear. This is particularly important in environments where hoses may be exposed to harsh conditions or frequent movement.

2. Safety Features Safety is a primary concern when handling LPG. Braided hoses are designed to withstand high pressures typically associated with LPG applications. The robust construction helps prevent leaks, which can lead to accidents and hazardous situations.

3. Flexibility and Maneuverability Despite their strength, LPG braided hoses are incredibly flexible, allowing for easy installation and movement around corners or tight spaces. This flexibility makes them an ideal choice for residential and commercial applications.

4. Temperature Resistance LPG braided hoses can operate effectively under a wide range of temperatures. This capability is crucial for applications where hoses might be exposed to heat sources or cold conditions.

5. Corrosion Resistance The materials used in braided hoses are often resistant to corrosion, further increasing their lifespan. This quality is essential in various applications, especially in industrial settings where exposure to chemicals is common.

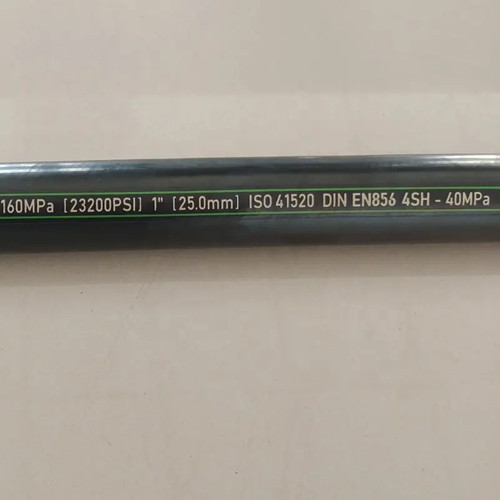

lpg braided gas hose

Safety Considerations

While LPG braided gas hoses offer numerous advantages, it is essential to prioritize safety when using them. Here are some critical safety tips

- Regular Inspections Periodically check for signs of wear and tear, cracks, or bulges in the hose. Replace any damaged hoses immediately to prevent leaks.

- Proper Installation Follow manufacturer guidelines for installation to ensure the hose is properly secured and connected. Avoid over-tightening connections, which can damage the hose.

- Use Appropriate Hoses Ensure the braided gas hose is rated for LPG use. Different hoses are designed for various gas types, and using the wrong hose can lead to dangerous situations.

- Monitoring for Leaks Regularly inspect connections for leaks, especially after installation or maintenance work. A simple soap and water solution can help identify leaks by creating bubbles where gas escapes.

- Professional Assistance When in doubt, consult with a certified technician for installation or troubleshooting. They can provide valuable insights and ensure compliance with safety standards.

Conclusion

In conclusion, LPG braided gas hoses are a vital component in the safe and efficient use of liquefied petroleum gas. Their combination of durability, flexibility, and safety features makes them an excellent choice for both residential and commercial applications. However, emphasizing safety by adhering to proper usage guidelines and conducting regular inspections can significantly reduce the risk of accidents and ensure a safe LPG experience. By choosing the right hose and maintaining it effectively, users can enjoy the benefits of LPG with peace of mind.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025