335345435

Gen . 09, 2025 13:54 Back to list

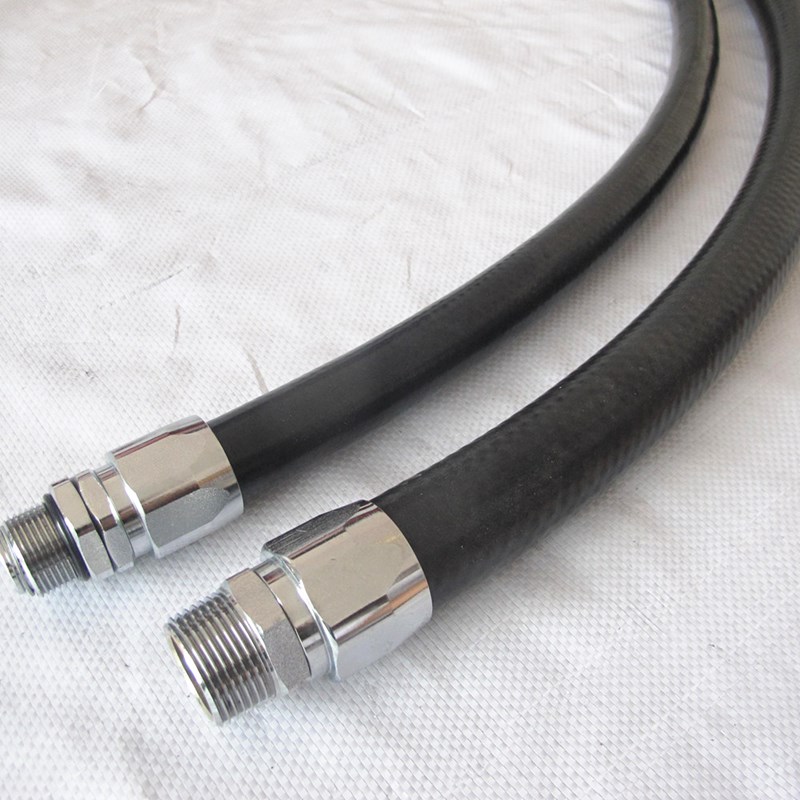

EN856 4SP Black smooth Cover Hydraulic Hose

The importance of selecting the right oil hose for industrial and automotive use cannot be overstated. As anyone who has worked with machinery knows, a reliable oil hose is essential for maintaining the efficiency and safety of operations. With years of experience in the field, I've witnessed firsthand how the proper selection and maintenance of oil hoses can drastically affect a project's success.

Temperature range is another critical consideration. An underestimated factor in the functionality and lifespan of an oil hose, temperature can affect both the internal flow and the external environment's impact on the hose material. Some hoses are specially designed to withstand extreme temperatures, both hot and cold, ensuring reliable performance across a range of climates and operational contexts. Authoritative knowledge in hose selection also draws upon industry standards and certifications. Trusted manufacturers ensure their products meet or exceed standards set by organizations such as SAE (Society of Automotive Engineers) or ISO (International Organization for Standardization). These certifications provide assurance of quality and reliability, and when selecting oil hoses, one should always prefer those that comply with these internationally recognized standards. Beyond the technicalities of oil hoses, trustworthiness in supply and service is critical. Engaging with suppliers that offer not only a range of certified products but also comprehensive support services is invaluable. Experienced partners provide essential insights and services, such as custom hose assemblies, on-site consultations, and troubleshooting, ensuring that the hose systems are optimally fitted to the specific application. In summary, the choice of an oil hose should be treated as an integral part of planning and maintaining any industrial or automotive system. The breadth of knowledge required encompasses understanding chemical compatibility, the mechanics of pressure systems, temperature influences, and adherence to industry standards. With the ideal hose, operations can achieve enhanced performance, reduced downtime, and improved safety, ultimately leading to significant cost savings and operational efficiency. Choosing the right oil hose is no small task, but with guidance grounded in experience, expertise, authority, and trustworthiness, it becomes a crucial step in ensuring the success and sustainability of an operation.

Temperature range is another critical consideration. An underestimated factor in the functionality and lifespan of an oil hose, temperature can affect both the internal flow and the external environment's impact on the hose material. Some hoses are specially designed to withstand extreme temperatures, both hot and cold, ensuring reliable performance across a range of climates and operational contexts. Authoritative knowledge in hose selection also draws upon industry standards and certifications. Trusted manufacturers ensure their products meet or exceed standards set by organizations such as SAE (Society of Automotive Engineers) or ISO (International Organization for Standardization). These certifications provide assurance of quality and reliability, and when selecting oil hoses, one should always prefer those that comply with these internationally recognized standards. Beyond the technicalities of oil hoses, trustworthiness in supply and service is critical. Engaging with suppliers that offer not only a range of certified products but also comprehensive support services is invaluable. Experienced partners provide essential insights and services, such as custom hose assemblies, on-site consultations, and troubleshooting, ensuring that the hose systems are optimally fitted to the specific application. In summary, the choice of an oil hose should be treated as an integral part of planning and maintaining any industrial or automotive system. The breadth of knowledge required encompasses understanding chemical compatibility, the mechanics of pressure systems, temperature influences, and adherence to industry standards. With the ideal hose, operations can achieve enhanced performance, reduced downtime, and improved safety, ultimately leading to significant cost savings and operational efficiency. Choosing the right oil hose is no small task, but with guidance grounded in experience, expertise, authority, and trustworthiness, it becomes a crucial step in ensuring the success and sustainability of an operation.

Share

Latest news

-

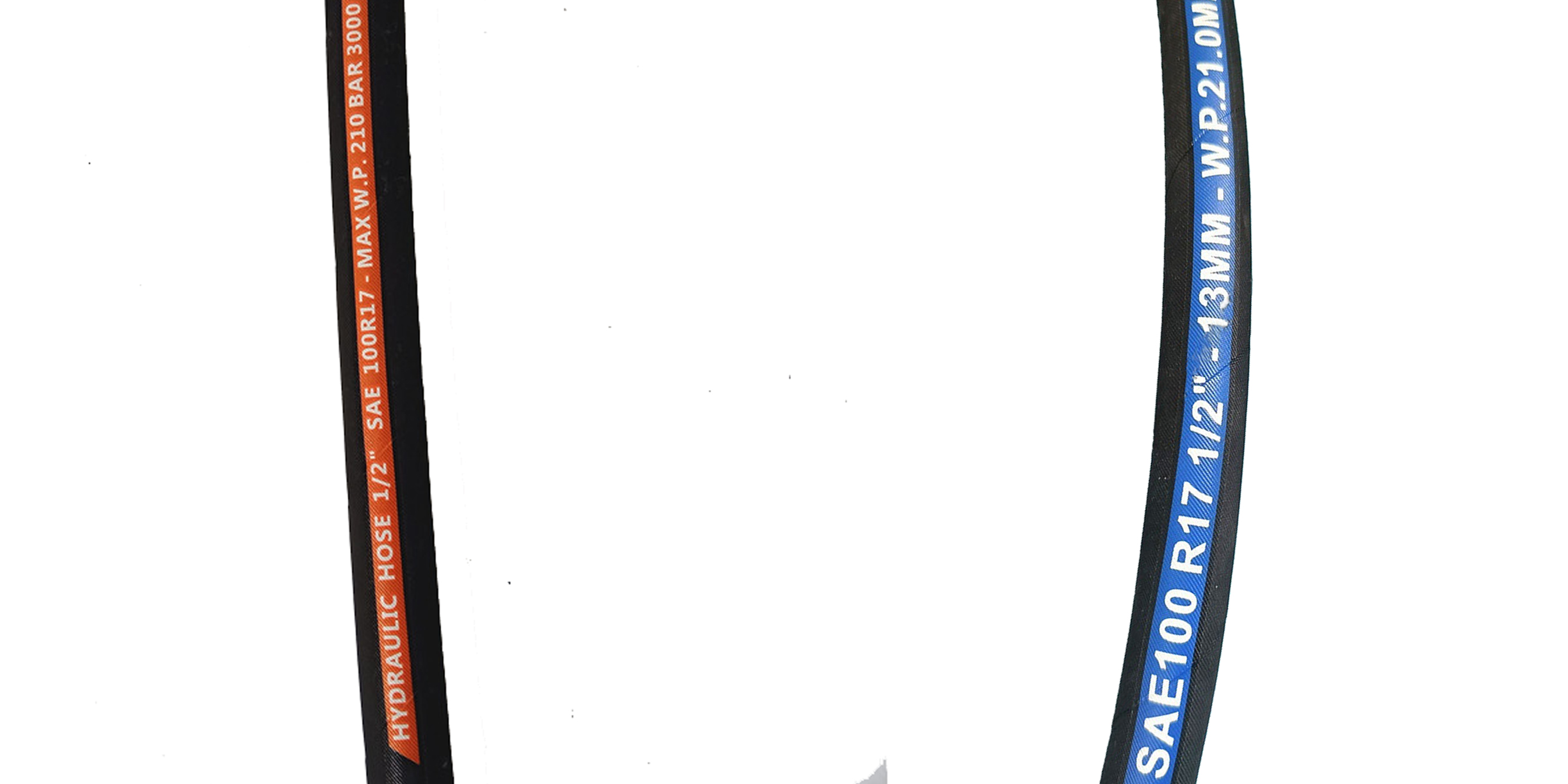

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025