335345435

Set . 30, 2024 17:52 Back to list

OEM Flexible Teflon Hose Suppliers for Custom Applications and Quality Solutions

The Evolution of OEM Teflon Flexible Hose Manufacturers

In the modern industrial landscape, flexibility and durability are key attributes for any type of hose used in various applications. Among these, Teflon (PTFE) flexible hoses have emerged as a preferred choice due to their unique properties, which include excellent chemical resistance, high temperature tolerance, and a low friction coefficient. Consequently, the demand for OEM (Original Equipment Manufacturer) Teflon flexible hose manufacturers is on the rise, transforming the market and influencing industries across the board.

Understanding Teflon Flexible Hoses

Teflon, a brand name for polytetrafluoroethylene (PTFE), was discovered in 1938 and has since become a material of choice in various applications. Teflon flexible hoses are renowned for their ability to handle a wide range of chemicals, from harsh acids to caustic substances, without compromising their integrity. Moreover, they can operate effectively in extreme temperatures, often ranging from as low as -100°F to as high as 500°F, making them invaluable in both high-pressure and high-temperature environments.

The construction of Teflon flexible hoses involves a blend of Teflon and other materials. The core may be pure PTFE or a PTFE lining wrapped with different materials such as stainless steel or rubber. This versatility allows these hoses to adapt to specific industrial requirements, which is a significant advantage offered by OEM manufacturers.

The Role of OEM Manufacturers

OEM Teflon flexible hose manufacturers play a pivotal role in ensuring that the hoses meet the precise needs of various industries, including pharmaceuticals, food processing, automotive, and petrochemical sectors

. Their contribution goes beyond mere production; they often engage in research and development to innovate and improve hose designs.These manufacturers are equipped to handle custom orders that cater to the specific requirements of clients, such as custom lengths, diameters, and pressure ratings. This adaptability is essential for industries where standard solutions may not suffice. Furthermore, many OEM manufacturers prioritize the use of high-quality materials to enhance the durability and performance of their products, ensuring that the hoses can withstand the rigorous demands of their intended applications.

oem teflon flexible hose manufacturers

Industry Trends and Innovations

As industries evolve, so too do the technologies and materials used in hose manufacturing. The trend towards automation and increased efficiency has prompted OEM Teflon flexible hose manufacturers to embrace advanced manufacturing techniques. Techniques such as 3D printing and automated hose assembly are becoming increasingly common, allowing manufacturers to produce more complex designs at a faster rate and lower cost.

Moreover, sustainability is becoming a more prominent focus in manufacturing practices. OEM manufacturers are increasingly conscious of their environmental impact and are seeking ways to incorporate sustainable practices into their operations. This can include using recyclable materials and implementing energy-efficient processes. By aligning with sustainability goals, manufacturers not only comply with regulations but also meet consumer demand for greener products.

Quality Assurance and Standards Compliance

Quality assurance is another crucial aspect of OEM Teflon flexible hose manufacturing. Manufacturers often adhere to industry standards and certifications such as ISO 9001, which ensures a systematic approach to quality management. Compliance with such standards helps build trust with clients, as it reflects a commitment to delivering high-quality products that meet safety and performance requirements.

Regular testing and inspection of hoses are also fundamental in maintaining quality. Many OEM manufacturers implement rigorous testing protocols that assess the pressure resistance, flexibility, and chemical resistance of their hoses. This proactive approach helps prevent failures in the field and reinforces the reliability of their products.

Conclusion

The landscape of OEM Teflon flexible hose manufacturing is dynamic and continually evolving. As industries grow and change, the demand for high-quality, flexible, and resilient hoses will only increase. OEM manufacturers, with their expertise in customization and commitment to innovation, are well-positioned to meet these demands. Not only do they enhance manufacturing capabilities, but they also contribute to safer and more efficient industrial operations worldwide. The future looks promising for Teflon flexible hoses and their manufacturers as they continue to adapt and evolve in an ever-changing market.

-

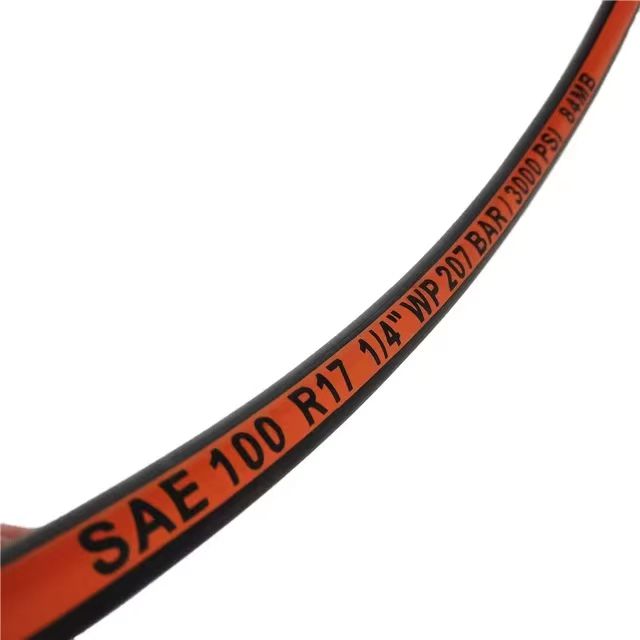

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025