335345435

Nov . 05, 2024 22:16 Back to list

High-Performance Rubber Fuel Lines for Optimal Pressure Systems

High Pressure Rubber Fuel Lines Essential Components for Modern Engines

Fuel delivery systems are crucial in the performance and efficiency of internal combustion engines. Among the various components that make up these systems, high pressure rubber fuel lines play a pivotal role. Designed to withstand the demanding environments of high pressure and temperature fluctuations, these fuel lines ensure the effective transport of fuel from the tank to the engine. This article will explore the features, benefits, and considerations associated with high pressure rubber fuel lines.

Composition and Design

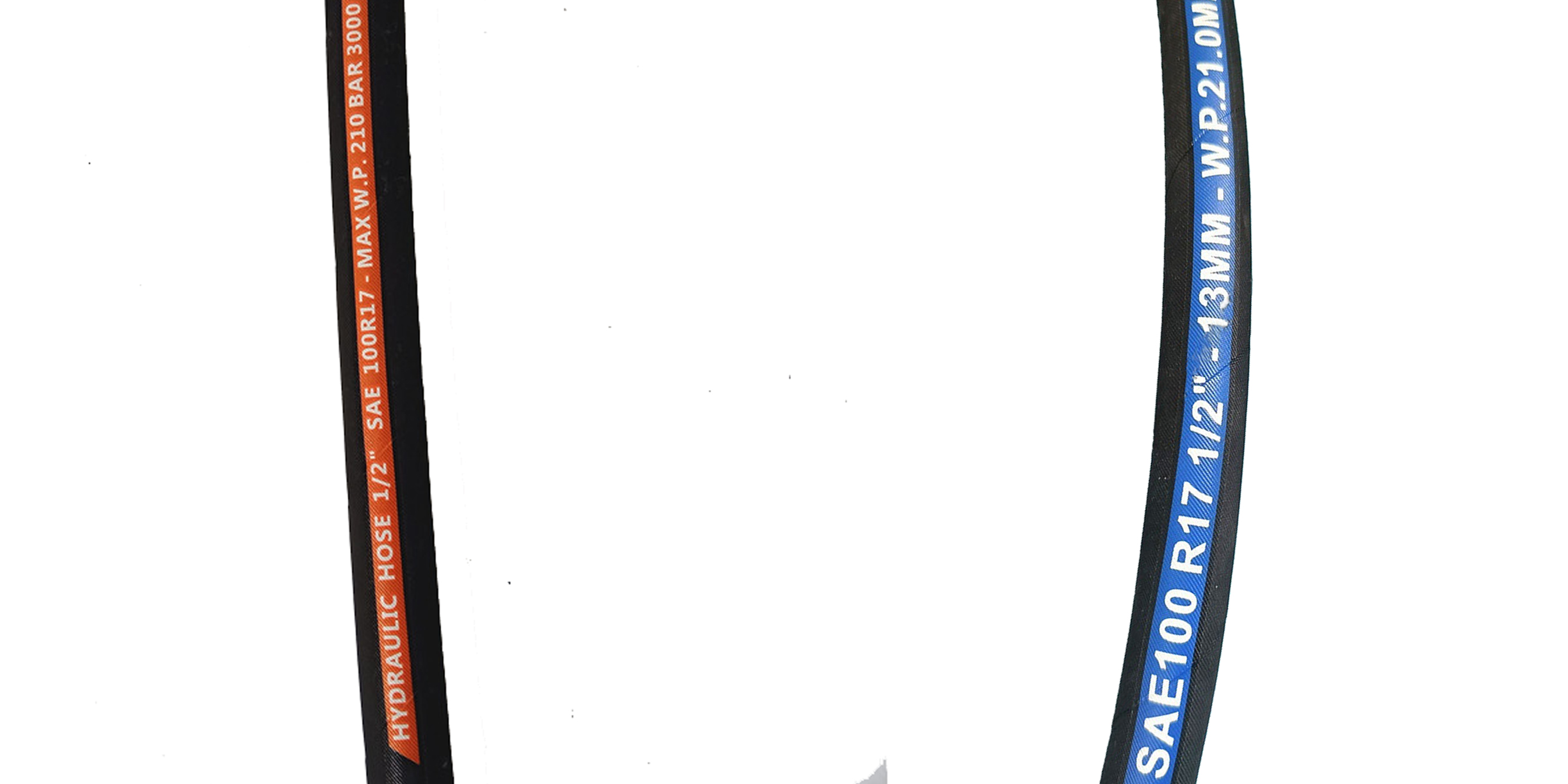

High pressure rubber fuel lines are typically made from a blend of synthetic rubber materials, reinforced with fabric or steel threads to enhance durability and resistance to pressure fluctuations. The rubber used is often resistant to fuels, oils, and various chemicals, preventing degradation over time. The design of these lines is specifically engineered to handle the higher pressures generated in modern fuel injection systems. In comparison to standard rubber lines, high pressure variants are thicker and have enhanced structural integrity.

Importance of High Pressure Capability

Modern engines require fuel delivery systems that operate at higher pressures to ensure optimal atomization of fuel for combustion. This is especially true for direct fuel injection systems, which can operate at pressures exceeding 200 bar (approximately 2900 psi). High pressure rubber fuel lines are designed to sustain these intense conditions, ensuring that fuel is effectively delivered to the combustion chamber. If these lines fail, it can lead to catastrophic fuel leaks, engine misfires, or decreased performance.

Advantages of Using Rubber Fuel Lines

1. Flexibility and Ease of Installation One of the primary advantages of rubber fuel lines is their inherent flexibility. This makes them easier to route around engine components and tight spaces, reducing the risk of kinks or bends that could disrupt fuel flow.

high pressure rubber fuel line

2. Vibration Resistance Engines produce significant vibrations, which can stress various components of the fuel system. High pressure rubber fuel lines are engineered to absorb these vibrations, minimizing wear and prolonging service life.

3. Cost-Effectiveness Compared to metal alternative materials, rubber fuel lines tend to be more affordable, making them an attractive option for vehicle manufacturers and aftermarket replacements.

4. Corrosion Resistance Unlike metal fuel lines that may rust or corrode over time, high pressure rubber lines are impervious to corrosive fuels and chemicals, enhancing their longevity.

Maintenance and Considerations

Despite their robust design, high pressure rubber fuel lines require regular inspection and maintenance. Over time, exposure to heat, moisture, and fuel can cause the lines to weaken, crack, or degrade. Signs of wear include visible cracks, swelling, or leaks. It’s essential to replace any damaged fuel lines promptly to maintain safety and engine performance.

When selecting high pressure rubber fuel lines for repairs or upgrades, it is critical to choose products that meet or exceed industry standards. Ensuring proper compatibility with the vehicle’s fuel system and adhering to manufacturer specifications can prevent premature failure. Additionally, using high-quality clamps and fittings during installation is vital to create a secure and leak-free connection.

Conclusion

High pressure rubber fuel lines are essential components of modern fuel delivery systems, providing the necessary flexibility, durability, and resistance to high pressure. Their ability to withstand harsh conditions while ensuring optimal fuel delivery is critical for the performance and safety of internal combustion engines. Regular inspection and timely replacement, alongside selecting quality products, will help maintain the efficiency and reliability of these vital components. In an age where performance and safety are paramount, understanding and valuing the role of high pressure rubber fuel lines can make a significant difference in vehicle operation and longevity.

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025