335345435

Jan . 09, 2025 10:43 Back to list

EN856 4SP Black smooth Cover Hydraulic Hose

Selecting the right oil hose for various industrial applications can significantly affect operational efficiency and safety. As an expert in the field of hydraulic and industrial hoses, my extensive experience in the industry has revealed that the subtleties of choosing oil hoses are often underestimated. However, understanding these subtleties is crucial for ensuring reliability, system efficiency, and longevity.

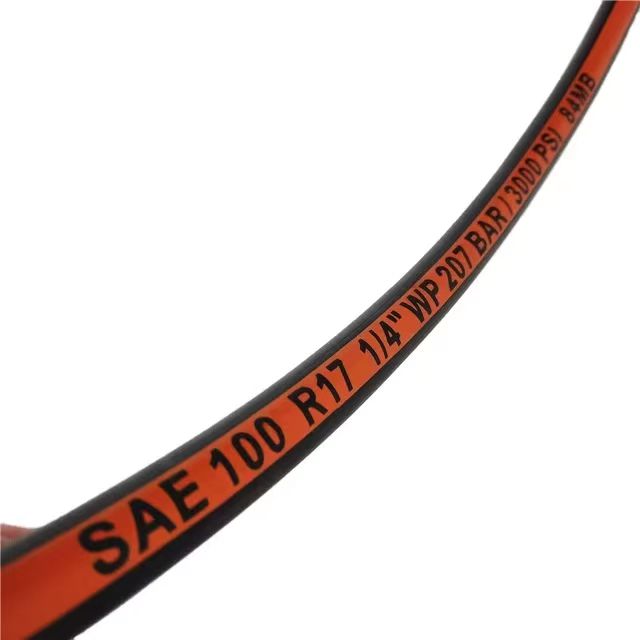

Another essential factor involves the hose fittings and connections. High-quality fittings made from stainless steel or brass resist corrosion and wear over time. Ensuring a correct and secure connection prevents leaks and potential hazards. Adopting screw clamps or crimped fittings can enhance the hose's performance and safety, which should always be performed by certified personnel to guarantee compliance with industry standards. From an authoritative standpoint, consulting with industry standards like those from the SAE (Society of Automotive Engineers) or ISO can provide valuable guidelines. These organizations provide benchmarks for safety, reliability, and performance, which are crucial for selecting a hose that meets both regulatory and functional expectations. Trusting these standards helps professionals maintain compliance and exhibit due diligence in their operations. In terms of installation and maintenance, regular inspections and timely replacements extend the lifespan of the oil hose and ensure operational safety. Signs of wear, such as cracks, leakage, or hardening, should prompt immediate action to avoid costly downtimes or accidents. By adopting a proactive maintenance strategy, industries can boost reliability and reduce unforeseen equipment failures. Ultimately, the right oil hose is vital for the safe and efficient transfer of oil in various applications, ranging from automotive to manufacturing. By applying professional knowledge and adhering to the outlined criteria, you not only safeguard your machinery but also enhance productivity and trust within your operational processes. This commitment to quality and safety fosters long-term reliability and underlines best practices in industrial operations.

Another essential factor involves the hose fittings and connections. High-quality fittings made from stainless steel or brass resist corrosion and wear over time. Ensuring a correct and secure connection prevents leaks and potential hazards. Adopting screw clamps or crimped fittings can enhance the hose's performance and safety, which should always be performed by certified personnel to guarantee compliance with industry standards. From an authoritative standpoint, consulting with industry standards like those from the SAE (Society of Automotive Engineers) or ISO can provide valuable guidelines. These organizations provide benchmarks for safety, reliability, and performance, which are crucial for selecting a hose that meets both regulatory and functional expectations. Trusting these standards helps professionals maintain compliance and exhibit due diligence in their operations. In terms of installation and maintenance, regular inspections and timely replacements extend the lifespan of the oil hose and ensure operational safety. Signs of wear, such as cracks, leakage, or hardening, should prompt immediate action to avoid costly downtimes or accidents. By adopting a proactive maintenance strategy, industries can boost reliability and reduce unforeseen equipment failures. Ultimately, the right oil hose is vital for the safe and efficient transfer of oil in various applications, ranging from automotive to manufacturing. By applying professional knowledge and adhering to the outlined criteria, you not only safeguard your machinery but also enhance productivity and trust within your operational processes. This commitment to quality and safety fosters long-term reliability and underlines best practices in industrial operations.

Share

Latest news

-

Reliable PTFE Hose Distribution | Flexible & High-Performance Solutions

NewsAug.27,2025

-

Distribution PTFE Hose: Flexible, Chemical-Resistant Solutions

NewsAug.26,2025

-

SAE 100 R1AT Hydraulic Hose: Smooth, Wrapped & Colourful

NewsAug.25,2025

-

Premium Distribution PTFE Hose | Flexible & Stainless Braided

NewsAug.23,2025

-

Premium Distribution PTFE Hose: Flexible & Durable Solutions

NewsAug.22,2025

-

SAE 100 R3 / EN854 R3 Hydraulic Hose | Medium Pressure & Flexible

NewsAug.11,2025