335345435

Des . 18, 2024 07:56 Back to list

oem ptfe flex hose supplier

The Role of OEM PTFE Flex Hose Suppliers in Modern Industries

In today's fast-paced industrial environment, the demand for high-quality materials and components is ever-increasing. One such component that has gained significant importance is the PTFE (Polytetrafluoroethylene) flex hose. Known for its exceptional chemical resistance, thermal stability, and anti-friction properties, PTFE flex hoses are indispensable in various industrial applications. As industries evolve, the role of Original Equipment Manufacturer (OEM) PTFE flex hose suppliers becomes crucial.

Understanding PTFE Flex Hoses

PTFE is a synthetic fluoropolymer that is widely known for its non-reactive and slippery properties. When formed into a hose, it can handle a wide range of temperatures, from cryogenic levels to over 260°C (500°F) for intermittent service. This makes PTFE flex hoses an optimal choice for transporting fluids and gases in processes where contamination must be minimized. Moreover, they offer excellent flexibility, making them easy to install in constrained spaces.

PTFE flex hoses are frequently used in industries such as pharmaceuticals, food and beverage, chemical processing, and semiconductor manufacturing, where the integrity of the transported materials is paramount. This versatility has led to the rise in demand for high-quality OEM suppliers who specialize in producing these hoses.

The Importance of OEM Suppliers

OEM suppliers of PTFE flex hoses play a pivotal role in ensuring that the hoses meet specific industry standards and customer requirements. These suppliers are often responsible for the design, manufacturing, and quality assurance of the hoses. By working closely with manufacturers, OEM suppliers provide tailored solutions that suit the particular needs of different industries.

1. Quality Assurance

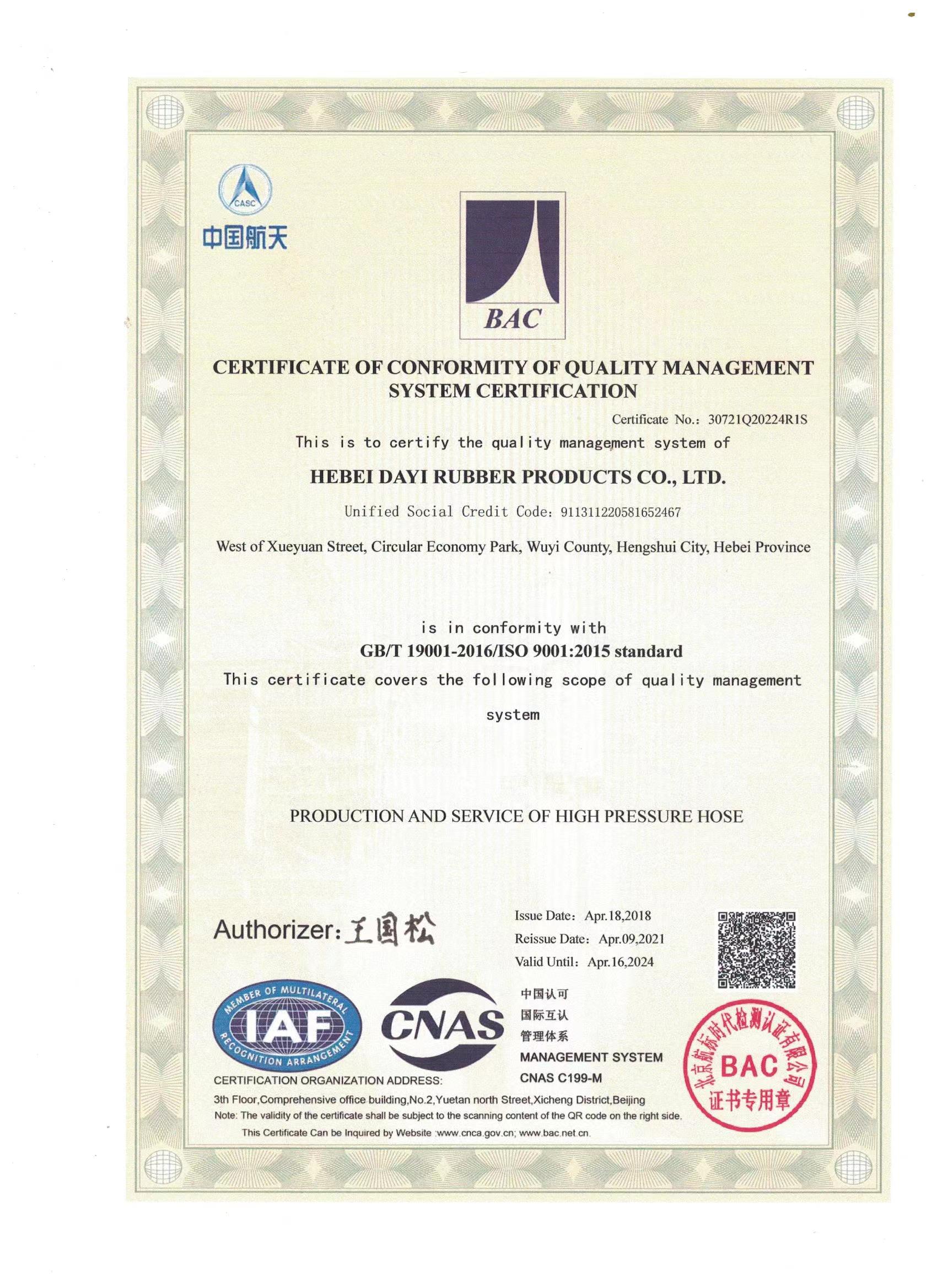

Quality is the cornerstone of any manufacturing process, particularly in industries that demand high standards for safety and efficiency. OEM PTFE flex hose suppliers are tasked with adhering to stringent quality control measures to ensure that each product meets regulatory requirements. This often involves rigorous testing and certification processes to validate the performance and durability of the hoses.

2. Customization

oem ptfe flex hose supplier

Every industry has its unique challenges, and OEM suppliers understand that a one-size-fits-all approach does not work. They collaborate with clients to develop customized PTFE flex hoses designed for specific applications. This includes modifications in length, diameter, and connection types, ensuring that every hose fits seamlessly into existing systems.

3. Innovation and Technology

The market for PTFE flex hoses is continuously evolving due to technological advancements. OEM suppliers invest in research and development to improve the performance of their products, often incorporating new manufacturing techniques and materials. This innovation enhances the durability and functionality of PTFE hoses, making them even more reliable for critical applications.

4. Cost Efficiency

Working with an OEM supplier can lead to cost savings in the long run. By ensuring that the hoses are manufactured to the precise specifications needed for a particular application, OEM suppliers reduce the risk of product failure and the associated costs of downtime and replacement. Additionally, their ability to produce bulk quantities often leads to lower prices per unit.

Industry Applications

The applications of PTFE flex hoses are vast and varied. In the pharmaceutical industry, they transport caustic and sensitive materials, ensuring that the integrity of the product is maintained during the process. In the food and beverage sector, the non-reactive nature of PTFE makes it safe for transporting consumable items while meeting stringent sanitary regulations. Furthermore, in the chemical processing industry, PTFE hoses handle corrosive chemicals that would degrade other types of hoses.

Conclusion

In conclusion, the demand for OEM PTFE flex hose suppliers is on the rise as industries strive for efficiency, safety, and innovation. These suppliers offer more than just a product; they provide expertise, customization, and quality assurance that are vital to the success of various applications. As technology continues to advance and industries evolve, the importance of these suppliers will undoubtedly grow, making them essential partners in the manufacturing landscape. Investing in high-quality PTFE flex hoses from reputable OEM suppliers is a strategic decision that can lead to long-term benefits for any organization, enhancing operational efficiency and ensuring the highest standards of safety and reliability.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025