335345435

Nov . 29, 2024 13:07 Back to list

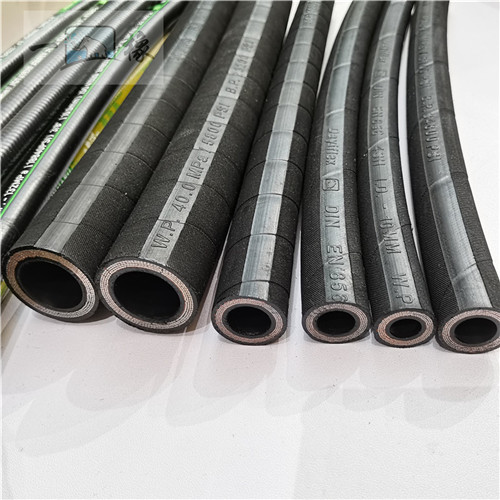

OEM EN 853 2SN Hydraulic Hose Manufacturers and Suppliers Options Available

Understanding OEM EN 853 2SN Hydraulic Hose Factories

The hydraulic industry plays a critical role in modern machinery and equipment, enabling effective fluid power transmission across various applications. At the core of this industry are hydraulic hoses, vital components designed to transport hydraulic fluids in a reliable and efficient manner. Among the various standards governing hydraulic hoses, the OEM EN 853 2SN specification stands out, ensuring performance, durability, and safety. This article explores the significance of OEM EN 853 2SN hydraulic hoses, the characteristics that define them, and the factories that manufacture these essential components.

What is OEM EN 853 2SN?

The OEM EN 853 2SN is a European standard that outlines the design and manufacturing requirements for high-pressure hydraulic hoses. The ‘EN’ stands for European Norm, indicating that this standard is widely accepted in Europe. The ‘853’ refers to the specific standard concerning rubber hoses and hose assemblies for hydraulic applications. The '2SN' designation signifies the construction type, which typically includes two steel wire braids providing reinforcement. This design enables the hose to withstand high pressures and aggressive operating conditions, making it suitable for a wide array of hydraulic applications.

Characteristics of OEM EN 853 2SN Hydraulic Hoses

1. High Pressure Resistance OEM EN 853 2SN hoses are engineered to operate under high pressure, often exceeding 200 bar (approximately 2,900 psi). The dual-wire braiding offers enhanced strength and stability.

2. Temperature Tolerance These hoses can function within a diverse temperature range, typically from -40°C to +100°C, with peaks reaching up to +125°C. This makes them suitable for use in various environments and conditions.

3. Compatibility with Hydraulic Fluids The materials used in the construction of EN 853 2SN hoses offer compatibility with a wide range of hydraulic fluids, including mineral oils, water-based fluids, and biodegradable fluids.

5. Safety Features The reinforced structure reduces the risk of hose ruptures, thereby enhancing operational safety. Additionally, many manufacturers incorporate advanced manufacturing techniques to minimize the likelihood of leaks.

The Manufacturing Process

oem en 853 2sn hydraulic hose factories

The production of OEM EN 853 2SN hydraulic hoses involves several critical stages

1. Material Selection High-quality rubber compounds and steel wires are selected based on the intended application's requirements. Durability, flexibility, and resistance to environmental factors are key considerations during this stage.

2. Hose Construction The process involves extruding the rubber to form the inner tube, followed by the insertion of steel wires for reinforcement. Subsequently, additional rubber layers are applied to form the outer cover.

3. Curing Process The assembled hoses undergo a curing process, also known as vulcanization. This step is vital as it transforms the rubber into a durable and elastic material, enhancing strength and temperature resistance.

4. Testing and Quality Control Each hose must pass stringent testing protocols to ensure it meets specifications outlined in the OEM EN 853 2SN standard. Tests may include pressure tests, temperature tests, and assessments for alignment with chemical compatibility standards.

Manufacturers and Factories

Numerous factories worldwide specialize in manufacturing OEM EN 853 2SN hydraulic hoses. These manufacturers often boast state-of-the-art facilities that incorporate advanced technology and quality control systems. Factory location plays a significant role, with many facilities strategically positioned to serve key markets in automotive, construction, and agricultural sectors.

Furthermore, leading manufacturers often prioritize sustainability in their production processes. This includes adopting eco-friendly materials and practices that minimize their environmental footprint, aligning with global trends towards sustainability and corporate responsibility.

Conclusion

The OEM EN 853 2SN hydraulic hose is a critical component in various industrial applications, offering durability, flexibility, and safety for fluid power transmission. The sophistication of the manufacturing process, combined with the stringent quality checks in factories, ensures that these hoses meet high standards. As technology and requirements continuously evolve, manufacturers remain committed to innovating and enhancing the hydraulic hose industry. Understanding the importance and characteristics of OEM EN 853 2SN hoses is essential for those involved in sectors reliant on hydraulic systems, promoting improved operational efficiency and safety across the board.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025