335345435

Jul . 25, 2024 23:55 Back to list

Exploring the Best Factories for Wrapped Cover Hydraulic Hoses and Their Manufacturing Processes

Wrapped Cover Hydraulic Hose Factories An Overview

In the world of industrial machinery and equipment, hydraulic hoses play a crucial role in ensuring smooth operation and efficient power transfer. Among the various types of hydraulic hoses, those with wrapped covers are particularly notable for their durability and resilience. This article explores the intricacies of wrapped cover hydraulic hose factories, focusing on their manufacturing processes, benefits, and applications.

Understanding Wrapped Cover Hydraulic Hoses

A wrapped cover hydraulic hose is designed with multiple layers, including a rubber or synthetic inner tube, wire reinforcement, and an outer cover that is often wrapped in a textile or rubber layer. This construction provides added protection against abrasion, weathering, and other environmental factors. The wrapped cover enhances the hose's resistance to physical damage and extends its lifespan, making it ideal for demanding applications.

The Manufacturing Process

Manufacturing wrapped cover hydraulic hoses involves several key steps. First, high-quality raw materials are selected, often including synthetic rubber, steel wire, and textile fibers. These materials are sourced from reputable suppliers to ensure consistency and reliability.

The process begins with the production of the inner tube. The rubber or synthetic material is extruded into a specific diameter and thickness, tailored to meet the required specifications. After the inner tube is formed, layers of wire reinforcement are added. This reinforcement is crucial as it provides the hose with the structural integrity needed to withstand high pressure and challenging working environments.

Once the core of the hose is ready, the wrapped cover is applied. This layer not only protects the hose from external damage but also provides flexibility and improved handling. Factories often use advanced techniques such as spiral wrapping or braiding to create the outer cover, ensuring that it adheres securely to the underlying layers.

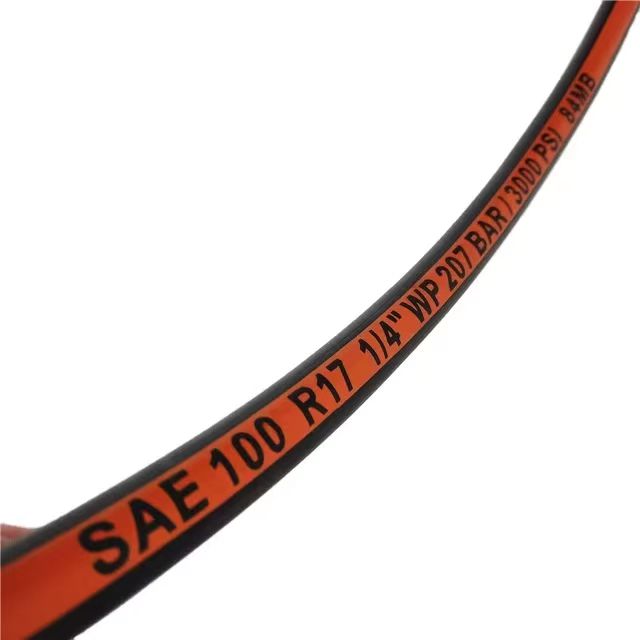

After the hose is assembled, it undergoes rigorous testing to ensure its quality and performance. This includes pressure tests, abrasion tests, and temperature resistance checks. Factories adhere to strict industry standards, such as ISO and SAE specifications, to guarantee that their products can withstand various operational conditions.

wrapped cover hydraulic hose factories

Benefits of Wrapped Cover Hydraulic Hoses

One of the primary advantages of wrapped cover hydraulic hoses is their enhanced durability. The protective outer layer significantly reduces the risk of damage from external factors, making them suitable for applications in industries such as construction, agriculture, and mining. These hoses are designed to withstand high-pressure environments, allowing for efficient fluid transfer and minimal downtime.

Another benefit is the versatility of wrapped cover hoses. They are available in a range of sizes and pressure ratings, making them adaptable to various machinery and applications. This flexibility allows manufacturers to produce hoses tailored to the specific needs of different industries, enhancing overall efficiency.

Moreover, wrapped cover hydraulic hoses demonstrate excellent resistance to temperature fluctuations and environmental conditions. Whether exposed to extreme heat, cold, or corrosive substances, these hoses maintain their integrity, ensuring reliable performance in any situation.

Applications

Wrapped cover hydraulic hoses are used across a multitude of sectors. In the construction industry, they connect heavy machinery such as excavators and bulldozers, transferring hydraulic fluid to power various operations. In agriculture, these hoses facilitate the operation of tractors and other equipment, ensuring that fluid is delivered effectively for tasks like plowing and planting. Additionally, they find applications in automotive, aerospace, and oil and gas sectors, highlighting their importance in diverse operational settings.

Conclusion

Wrapped cover hydraulic hose factories play a vital role in the production of high-quality hoses essential for various industries. Their manufacturing processes ensure durability, versatility, and reliability, making wrapped cover hydraulic hoses a preferred choice for professionals worldwide. As industries continue to evolve, the demand for these robust hoses will undoubtedly persist, driven by the need for efficiency and performance in hydraulic systems.

-

High-Precision Hydraulic Hose Crimping Machine for Fast, Reliable Fittings

NewsJul.24,2025

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025