335345435

jan . 22, 2025 01:14 Back to list

ptfe stainless braided hose

PTFE stainless braided hoses have revolutionized industries that require precision, durability, and chemical resistance. As a seasoned engineer with extensive expertise in fluid transfer applications, I can attest to the exceptional performance and versatility these hoses bring to various sectors, from automotive to pharmaceuticals.

Moreover, PTFE stainless braided hoses stand out in operational efficiency and long-term cost-effectiveness. Users report substantial reductions in maintenance costs, given the hoses' robustness and resistance to wear and tear. This longevity translates to fewer replacements and downtimes, boosting productivity and minimizing operational costs. As a testament to their reliability, companies worldwide have standardized PTFE stainless braided hoses as integral components in fluid handling systems. Despite their high initial costs, experts vouch for the long-term savings and peace of mind these hoses provide. Their capacity to deliver exceptional performance over extended periods justifies the investment, positioning them as a cost-effective solution amidst tight budgeting constraints. This insight reflects a broader trend toward investing in durable, environmentally friendly materials that pay off over time. The confidence in PTFE stainless braided hoses is further buoyed by their compliance with rigorous industry standards. They are designed to meet ASTM, SAE, and FDA requirements, among others. This compliance not only attests to their quality and safety but also aligns with regulatory expectations across different industries. The assurance that these hoses are manufactured to the highest standards enhances trust and reliability on a global scale. In conclusion, PTFE stainless braided hoses embody the pinnacle of innovation and practicality in fluid processing applications. Their remarkable characteristics—durability, flexibility, and chemical resistance—are matched by their compliance with stringent standards, fostering trust and confidence among users. The investment in these hoses transcends mere cost considerations, positioning them as vital assets in achieving operational efficiency and safeguarding product quality across multiple industries. By integrating PTFE stainless braided hoses into your systems, you are embracing a solution that not only meets today's demands but anticipates tomorrow's challenges.

Moreover, PTFE stainless braided hoses stand out in operational efficiency and long-term cost-effectiveness. Users report substantial reductions in maintenance costs, given the hoses' robustness and resistance to wear and tear. This longevity translates to fewer replacements and downtimes, boosting productivity and minimizing operational costs. As a testament to their reliability, companies worldwide have standardized PTFE stainless braided hoses as integral components in fluid handling systems. Despite their high initial costs, experts vouch for the long-term savings and peace of mind these hoses provide. Their capacity to deliver exceptional performance over extended periods justifies the investment, positioning them as a cost-effective solution amidst tight budgeting constraints. This insight reflects a broader trend toward investing in durable, environmentally friendly materials that pay off over time. The confidence in PTFE stainless braided hoses is further buoyed by their compliance with rigorous industry standards. They are designed to meet ASTM, SAE, and FDA requirements, among others. This compliance not only attests to their quality and safety but also aligns with regulatory expectations across different industries. The assurance that these hoses are manufactured to the highest standards enhances trust and reliability on a global scale. In conclusion, PTFE stainless braided hoses embody the pinnacle of innovation and practicality in fluid processing applications. Their remarkable characteristics—durability, flexibility, and chemical resistance—are matched by their compliance with stringent standards, fostering trust and confidence among users. The investment in these hoses transcends mere cost considerations, positioning them as vital assets in achieving operational efficiency and safeguarding product quality across multiple industries. By integrating PTFE stainless braided hoses into your systems, you are embracing a solution that not only meets today's demands but anticipates tomorrow's challenges.

Share

Latest news

-

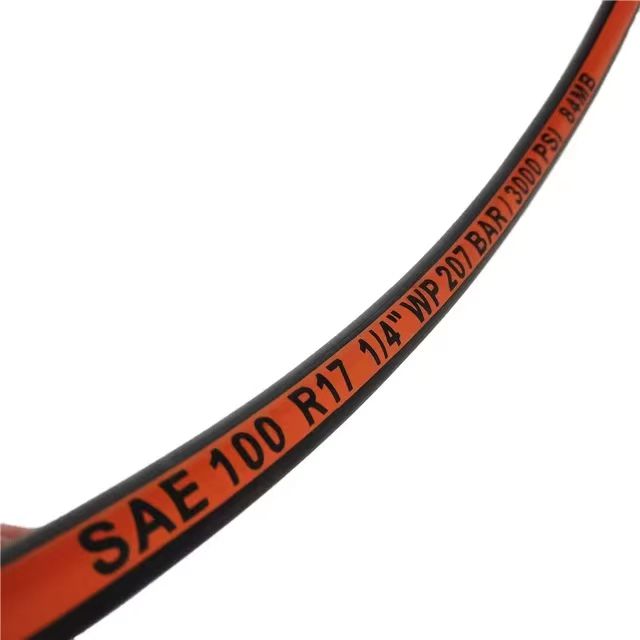

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025