335345435

dec . 07, 2024 03:54 Back to list

oem high pressure steel wire braided hydraulic hose factories

OEM High Pressure Steel Wire Braided Hydraulic Hose Manufacturers An Overview

Hydraulic systems play a crucial role in various industries, from construction and agriculture to manufacturing and automotive. One of the key components that ensure the effectiveness and reliability of these systems is the hydraulic hose. Among the different types available, high-pressure steel wire braided hydraulic hoses are renowned for their durability and performance under extreme conditions. This article explores the characteristics, manufacturing processes, and the importance of Original Equipment Manufacturer (OEM) factories in producing these essential components.

Characteristics of High Pressure Steel Wire Braided Hydraulic Hoses

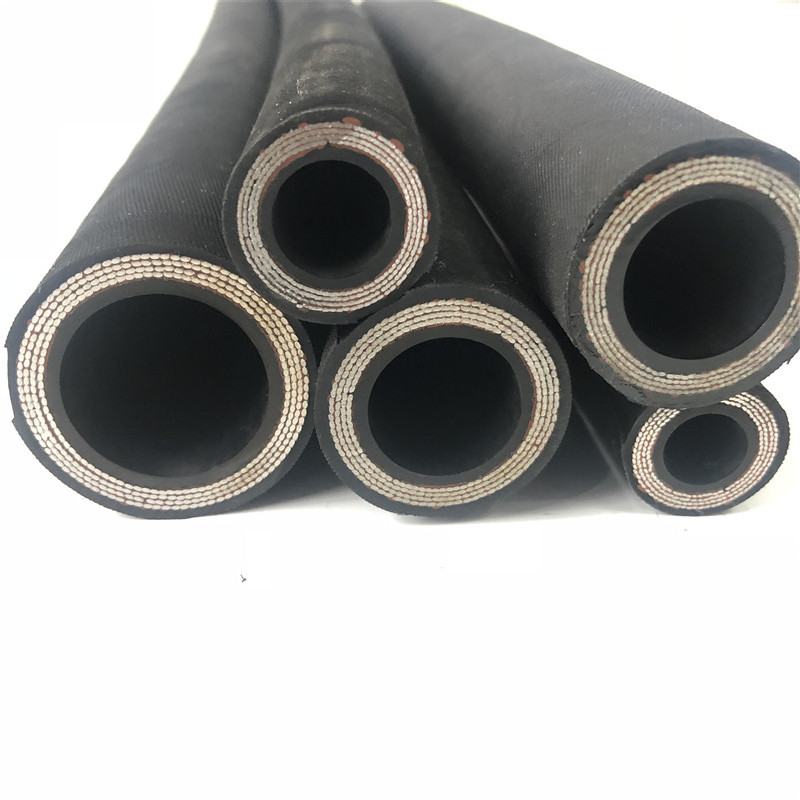

High-pressure steel wire braided hydraulic hoses are designed to withstand significant pressure and provide flexibility in applications where movement is essential. These hoses typically consist of three main components an inner tube, a steel wire braid reinforcement, and an outer cover. The inner tube is made from high-quality rubber or thermoplastic that carries the hydraulic fluid. Surrounding this tube is a layer of steel wire braiding that enhances the hose's strength and pressure resistance, often allowing it to tolerate pressures up to several thousand psi. Finally, the outer cover protects the hose from environmental factors such as abrasion, oil, and UV radiation.

The high tensile strength of the steel wire ensures that the hose remains intact under extreme pressure and operational stress, making it a preferred choice for demanding hydraulic applications and machinery.

Manufacturing Process of Hydraulic Hoses

The manufacturing process of high-pressure steel wire braided hydraulic hoses involves several steps that require precision and quality control. It begins with the selection of raw materials, where manufacturers source high-grade rubber, steel, and other components. The inner rubber tube is extruded, followed by the application of the steel wire braid, which is formed by wrapping and interweaving the steel wires around the rubber tube under high tension.

oem high pressure steel wire braided hydraulic hose factories

Next, the outer cover is added, which may incorporate additional protective elements such as chemical-resistant compounds. The entire assembly is cured in a pressurized chamber to solidify the materials and enhance their durability. Finally, each hose undergoes rigorous testing to ensure it meets industry standards for pressure tolerance and flexibility.

Importance of OEM Factories

The role of OEM factories in the production of high-pressure steel wire braided hydraulic hoses cannot be overstated. These manufacturers are responsible for producing components that meet the stringent specifications required by original equipment manufacturers. This relationship is essential for ensuring that the hydraulic components are compatible with specific machinery and can perform reliably in diverse applications.

OEM factories often invest in advanced technologies and machinery, allowing for higher precision in the manufacturing process. They also focus on quality assurance through testing and verification processes, which help to maintain high standards across their products. By partnering with OEM factories, companies can guarantee that they are using hoses that not only meet but exceed performance expectations.

Conclusion

In summary, OEM high-pressure steel wire braided hydraulic hoses are vital components in hydraulic systems used across various industries. Their robust design allows for high-pressure operations while maintaining flexibility and resistance to environmental wear. The intricate manufacturing processes and the dedication of OEM factories ensure these hoses are produced to the highest standards, meeting the rigorous demands of modern hydraulic applications. As industries continue to evolve and expand, the importance of high-quality hydraulic hoses will remain paramount, driving innovation and performance in hydraulic systems worldwide.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025