335345435

nov . 27, 2024 07:52 Back to list

Essential Guide to Hydraulic Hoses and Fittings for Efficient Fluid Power Systems

Understanding Hydraulic Hoses and Fittings Essential Components for Fluid Power Systems

Hydraulic systems serve as the backbone for many industrial applications, enabling machinery to operate with efficiency and precision. Central to these systems are hydraulic hoses and fittings, which facilitate the transfer of hydraulic fluids under pressure. To fully grasp their significance, we must delve into the types, materials, applications, and best practices related to hydraulic hoses and fittings.

Types of Hydraulic Hoses

Hydraulic hoses are specially engineered to withstand high pressures and diverse environmental conditions. The primary types of hydraulic hoses include

1. Wire-Braided Hoses These hoses consist of multiple layers of steel wire, providing excellent pressure resistance. They are ideal for high-pressure applications, such as those found in heavy machinery and construction equipment.

2. Spiral Hoses Constructed with multiple layers of wire twisted into a spiral, these hoses are designed for even higher pressures. Spiral hoses are often used in extremely demanding environments like mining and oil rigs.

3. Thermoplastic Hoses Made from materials like polyurethane or nylon, these hoses are lightweight and flexible. They are suitable for applications requiring flexibility and chemical resistance, making them popular in the agriculture and automotive industries.

Fitting Options

Fittings are essential connectors that link hydraulic hoses to various components in a hydraulic system. The main types of hydraulic fittings include

1. Screw-on Fittings These are commonly used for their simplicity and ease of installation. They are often utilized in low-pressure applications.

2. Flange Fittings Designed for high-pressure applications, flange fittings create a strong, leak-proof seal. They are commonly seen in large industrial equipment.

3. Push-on Fittings These fittings allow hoses to be quickly and easily connected without the need for clamps or tools. They are suitable for low-pressure applications.

Materials and Construction

The performance of hydraulic hoses and fittings hinges on their materials. High-quality materials are crucial for durability and reliability. Commonly used materials include

- Rubber Known for its flexibility and resilience, rubber is often used for standard hydraulic hoses

. - Polyurethane This is lightweight and has excellent abrasion resistance, making it suitable for demanding environments.hydraulic hoses and fittings pdf

- Steel Used extensively in fittings, steel offers high strength and resistance to corrosion, essential for maintaining system integrity.

Applications of Hydraulic Hoses and Fittings

Hydraulic hoses and fittings find applications in an array of industries, including

- Construction Heavy machinery such as excavators and bulldozers rely on hydraulic systems for operation.

- Agriculture Tractors and harvesters utilize hydraulic hoses for efficient operation.

- Automotive From braking systems to power steering, hydraulics play a crucial role in vehicle safety and performance.

- Manufacturing Robotics and assembly lines employ hydraulic systems for precision and speed.

Best Practices for Maintenance

To ensure optimal performance and longevity of hydraulic hoses and fittings, several maintenance practices should be followed

- Regular Inspections Routinely check for signs of wear, leaks, or damage. Early detection can prevent catastrophic failures.

- Proper Installation Follow manufacturer guidelines for installation to avoid issues related to improper fitting or hose routing.

- Fluid Compatibility Ensure that the hydraulic fluid used is compatible with the hose and fitting materials to prevent degradation.

- Pressure Monitoring Regularly monitor operating pressures to ensure they remain within the recommended limits of the hoses and fittings.

Conclusion

Hydraulic hoses and fittings are indispensable components of fluid power systems, playing a critical role in a wide range of applications. Understanding their types, materials, and best practices not only enhances operational efficiency but also contributes to safety and compliance with industry standards. As industries continue to evolve, investing in quality hydraulic components and maintaining them diligently will be essential for ensuring reliable and effective hydraulic operations. By prioritizing these systems, businesses can achieve greater productivity and minimize downtime, which is vital in today’s fast-paced industrial landscape.

-

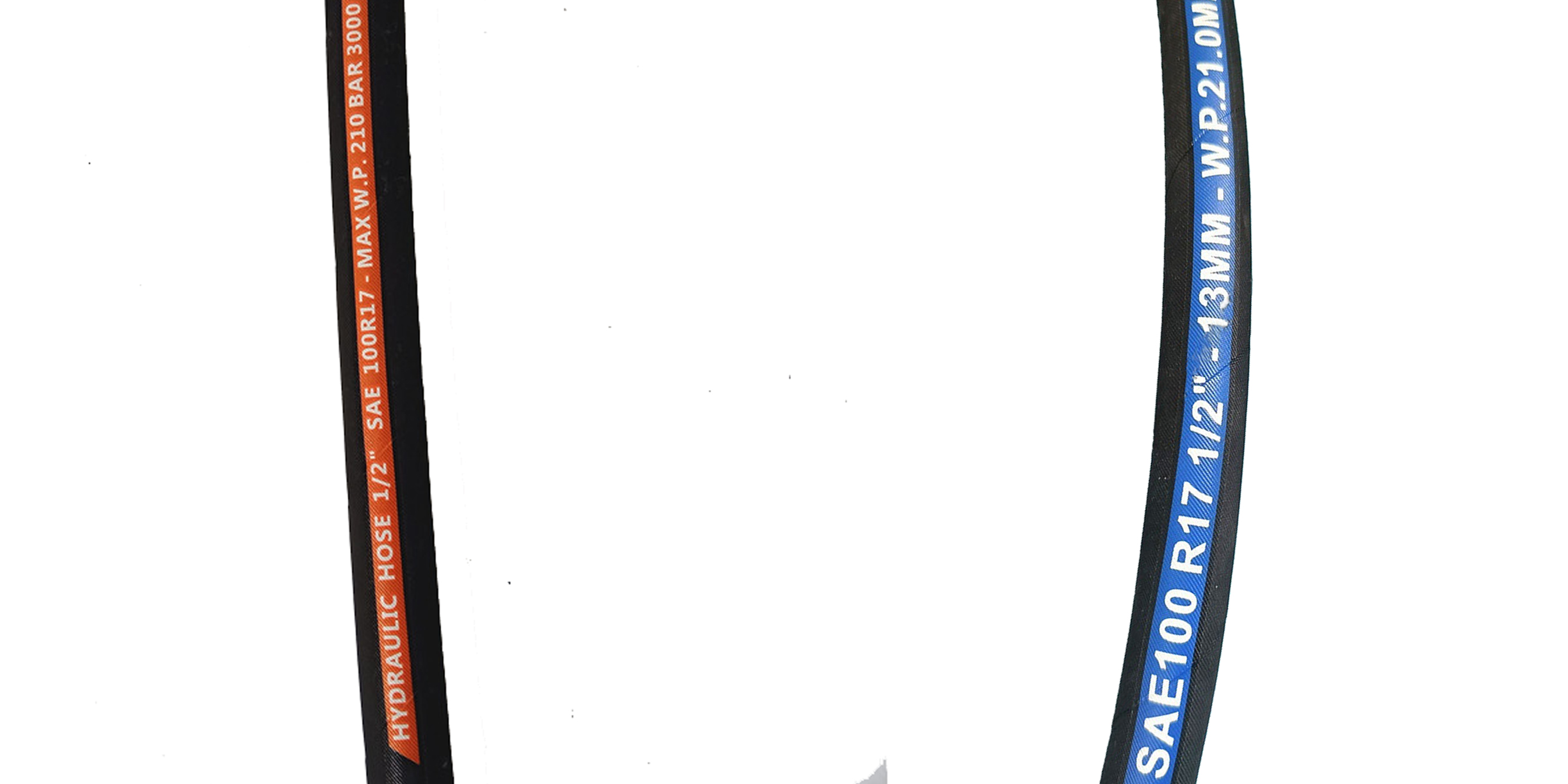

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025