335345435

Dec . 11, 2024 10:13 Back to list

Teflon Hose Manufacturing Facilities and Their Key Features in Modern Industry

The Rise and Development of Teflon Hose Factories

In recent years, the industrial landscape has seen significant advancements in materials and manufacturing processes. Among these innovations, Teflon hoses have emerged as a crucial component in various applications due to their unique properties. Teflon, or polytetrafluoroethylene (PTFE), is known for its remarkable chemical resistance, high-temperature tolerance, and non-stick characteristics. These attributes have propelled Teflon hoses into the limelight, leading to the establishment and growth of Teflon hose factories around the globe.

The demand for Teflon hoses has grown exponentially in industries such as automotive, chemical processing, pharmaceuticals, and food service. Their ability to withstand a wide range of temperatures and corrosive environments makes them ideal for conveying fluids, gases, and powders in harsh conditions. Manufacturers are increasingly relying on Teflon hoses for their reliability and performance, prompting a surge in factory establishments dedicated to their production.

The Rise and Development of Teflon Hose Factories

Moreover, advancements in manufacturing technologies have played a significant role in the growth of Teflon hose factories. Modern production methods, including extrusion and molding techniques, allow for the efficient and cost-effective production of Teflon hoses. These innovations have lowered the barriers to entry for new manufacturers while enabling established factories to enhance their production capabilities, leading to increased output and a broader range of products.

teflon hose factories

Environmental considerations have also influenced the growth of Teflon hose factories. As sustainability becomes a central focus for many industries, the demand for recyclable and long-lasting materials has surged. Teflon’s durability means that products have a long lifecycle, thereby reducing waste and environmental impact. Factories are thus positioned to capitalize on this trend by producing Teflon hoses that align with eco-friendly initiatives.

In addition to environmental factors, the global market dynamics have prompted factories to explore export opportunities. The versatility of Teflon hoses allows them to cater to diverse markets worldwide. As industries in developing countries grow, the need for high-quality hoses has increased, driving demand for Teflon products. Teflon hose factories must therefore adapt their strategies to meet international standards and regulations to capture these emerging markets effectively.

Investments in research and development have become pivotal for Teflon hose factories aiming to differentiate themselves in a competitive market. By exploring innovative designs and applications, manufacturers can create specialized hoses tailored to specific customer needs. Whether it involves developing hoses with unique diameters, pressure ratings, or enhanced flexibility, innovation is key to maintaining a competitive edge.

However, the growth of Teflon hose factories is not without challenges. The fluctuating prices of raw materials, coupled with evolving consumer preferences, require manufacturers to remain agile and responsive. Additionally, as competition increases, maintaining product quality while managing costs becomes a critical balancing act.

In conclusion, Teflon hose factories have emerged as vital players in the industrial sector due to the increasing demand for high-performance materials. Their unique properties make Teflon hoses indispensable across various applications, from chemical processing to food production. As these factories continue to innovate and respond to market demands, they will play a crucial role in shaping the future of manufacturing, sustainability, and safety in industrial operations. Through strategic planning and investment in technology, Teflon hose factories can not only thrive in the current market but also pave the way for future advancements in material science and manufacturing processes.

-

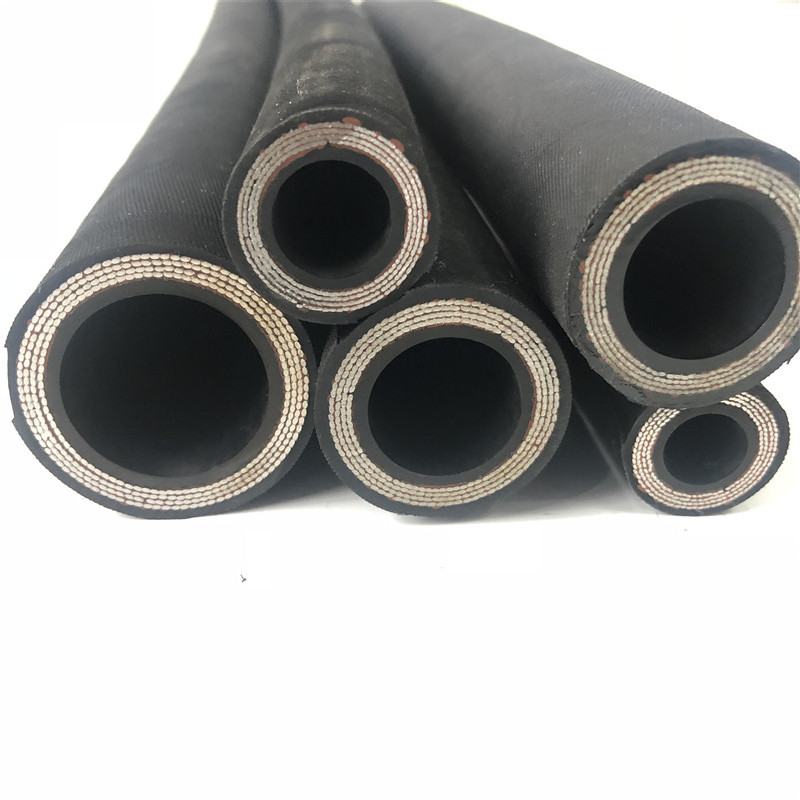

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025