335345435

Dec . 09, 2024 17:40 Back to list

OEM Hydraulic Hose Press Manufacturing Solutions for High-Quality Performance and Durability

Understanding OEM Hydraulic Hose Press Factories

In the realm of industrial manufacturing, hydraulic hoses play a critical role in ensuring efficient operation in various applications, from construction equipment to automotive systems. Original Equipment Manufacturers (OEMs) rely heavily on the quality and reliability of hydraulic components, which has led to a burgeoning market for hydraulic hose press factories. These factories not only manufacture hydraulic hoses but also ensure that they meet strict quality standards, thereby playing an integral role in the supply chain.

The Role of OEM in Manufacturing

Original Equipment Manufacturers are companies that produce parts and equipment that may be marketed by another manufacturer. For hydraulic hoses, OEMs require custom specifications to suit their applications, whether it's for heavy machinery, agricultural equipment, or high-performance vehicles. The vast array of environments and pressures in which these hoses operate means that precision and quality in manufacturing are paramount.

The Functionality of Hydraulic Hoses

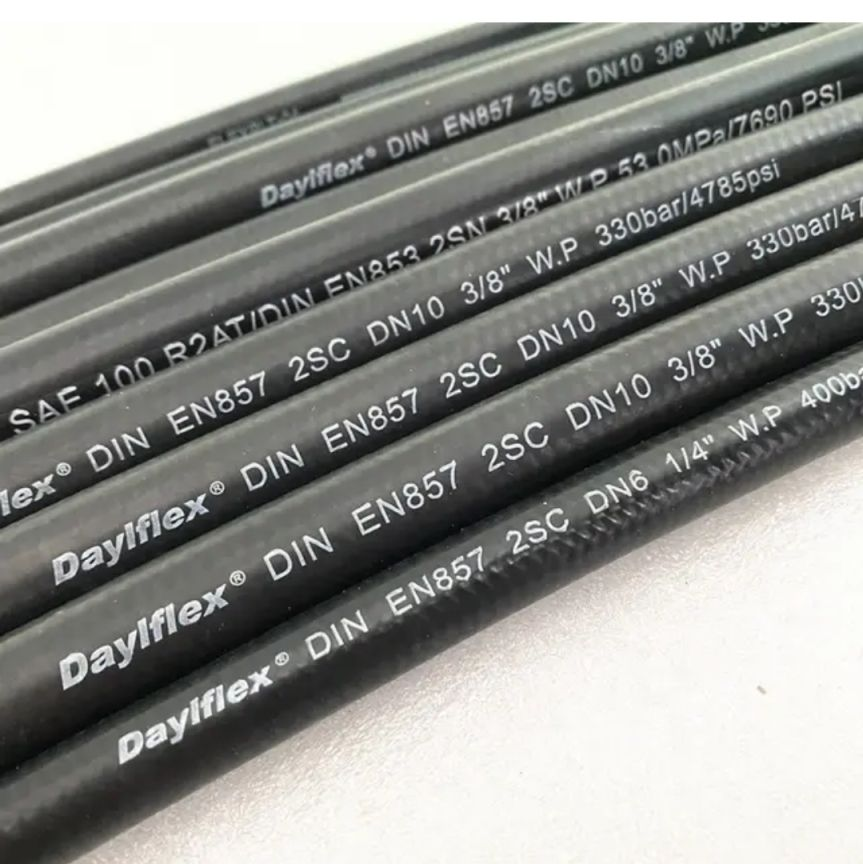

Hydraulic hoses are critical components designed to transfer hydraulic fluid between different systems, ensuring that machinery and equipment operate smoothly and effectively. These hoses must endure high pressures and extreme temperatures, making their durability essential. Hydraulic hose press factories focus on producing hoses that not only meet but exceed industry standards, thus providing OEMs with reliable products.

The Process of Manufacturing Hydraulic Hoses

The manufacturing process at hydraulic hose press factories begins with selecting high-quality raw materials, typically rubber or thermoplastic composites. These materials are chosen based on their resistance to wear, weather, and pressure. The production involves several critical steps

1. Cutting and Preparation Raw materials are cut to specific sizes and prepared for further processing. 2. Reinforcement Most hydraulic hoses are reinforced with layers of steel wire or fabric to enhance their strength. This step is crucial for ensuring that hoses can withstand high pressures.

4. Testing Quality assurance practices involve rigorous testing, including burst tests and pressure tests, to identify any potential weaknesses or defects.

oem hydraulic hose press factories

5. Certification Post-testing, the hoses are often certified to meet various industry standards, enabling OEMs to trust the reliability of the components they are purchasing.

Importance of Quality Control

Quality control is a cornerstone of the production process in hydraulic hose press factories. Given the potential risks associated with hydraulic failures—ranging from equipment damage to safety hazards—ensuring the reliability of these components is not merely a legal obligation; it is fundamental to the manufacturer’s reputation and customer trust. Regular audits and comprehensive testing protocols help maintain high standards.

Advantages of Partnering with Hydraulic Hose Press Factories

For OEMs, partnering with reputable hydraulic hose press factories can lead to several advantages

- Customization Factories that specialize in hydraulic hoses can offer tailored solutions that align with the unique requirements of an OEM's applications. - Cost-Effectiveness Establishing a partnership can lead to bulk purchasing benefits and reduced costs, which can enhance margins.

- Technical Support Many factories provide technical assistance and guidance, helping OEMs choose the right specifications for their needs.

- Reliability When OEMs source from reputable manufacturers, they can ensure a consistent supply of high-quality components, essential for maintaining production schedules and meeting customer demands.

Conclusion

The landscape of hydraulic hose manufacturing is evolving, driven by the demands of OEMs and the necessity for high-quality components. Hydraulic hose press factories play a crucial role in this ecosystem, ensuring that the hoses produced not only meet rigorous performance standards but also support the wide array of industries that rely on hydraulic systems. As technology advances and the need for enhanced performance grows, these factories will continue to innovate, ensuring that they remain valuable partners for OEMs in the pursuit of excellence.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025