335345435

Dec . 19, 2024 00:01 Back to list

OEM Manufacturer of Hydraulic Hose Fittings for Various Industrial Applications

OEM Hydraulic Hose Fittings Manufacturer Ensuring Quality and Performance

In today's industrial landscape, the demand for high-quality hydraulic systems is greater than ever. Hydraulic systems are essential in various applications, from construction and agriculture to manufacturing and automotive. One of the critical components that determine the efficiency and performance of these systems is hydraulic hose fittings. An Original Equipment Manufacturer (OEM) specializing in hydraulic hose fittings plays a crucial role in ensuring that these systems operate smoothly and reliably.

Understanding Hydraulic Hose Fittings

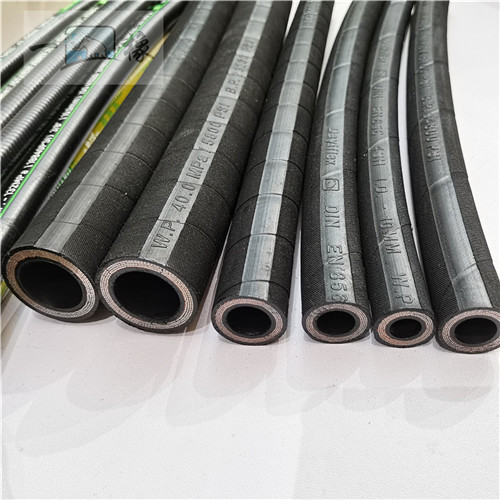

Hydraulic hose fittings are mechanical devices that connect hoses to various components within a hydraulic system, such as pumps, valves, and cylinders. These fittings come in various shapes and sizes, designed to accommodate different types of hoses and operating pressures. Their primary function is to ensure a secure and leak-free connection that can withstand high-pressure scenarios typical of hydraulic applications.

Choosing the right fittings is essential, as improper fittings can lead to leaks and system failures, ultimately resulting in downtime and increased maintenance costs. Therefore, working with a reliable OEM hydraulic hose fittings manufacturer is vital for ensuring that the components meet industry standards and performance specifications.

The Importance of OEM Manufacturers

OEM manufacturers specialize in producing parts that are designed to fit specific machines or systems. They focus on producing high-quality products that meet both the technical requirements and specifications of original equipment. Collaborating with an OEM hydraulic hose fittings manufacturer guarantees that the fittings are designed not only for compatibility but also for durability and performance.

1. Customization and Precision Engineering

One of the significant advantages of working with an OEM manufacturer is the ability to customize products to meet specific needs. OEM manufacturers often utilize advanced engineering techniques and technologies to design fittings tailored to the exact specifications of their clients. This level of customization ensures that the fittings will perform optimally within a given system.

OEM manufacturers are often at the forefront of innovation, utilizing the latest materials and manufacturing processes. They employ precision engineering to ensure a perfect fit, minimizing the risk of leaks and malfunctions in the hydraulic systems.

oem hydraulic hose fittings manufacturer

2. Quality Assurance and Testing

Quality assurance is a critical aspect of the manufacturing process in the hydraulic industry. Reputable OEM manufacturers implement strict quality control measures to ensure that every fitting produced meets high standards of quality and reliability. This often includes rigorous testing under various conditions to simulate real-world operating scenarios.

When sourcing fittings from an OEM manufacturer, customers can have assurance that each component has undergone thorough inspections and testing. This not only enhances the safety and efficacy of hydraulic systems but also extends the lifespan of the equipment.

3. Compliance with Industry Standards

The hydraulic industry is governed by various regulations and standards, including ISO and SAE specifications. An OEM hydraulic hose fittings manufacturer stays updated with these standards, ensuring that their products comply with all necessary regulations. Adhering to these guidelines is essential for safety, reliability, and performance, making it crucial for OEM manufacturers to maintain rigorous compliance.

Benefits of Choosing OEM Fittings

By opting for OEM hydraulic hose fittings, clients can reap several benefits

- Improved Reliability OEM fittings are designed for durability and reliability, reducing the risk of failure. - Enhanced Efficiency Properly designed and manufactured fittings contribute to the overall efficiency of hydraulic systems by ensuring optimal flow and reducing pressure drops. - Cost-Effective Solutions While OEM fittings may have a higher upfront cost, their longevity and reliability often translate to lower overall maintenance and replacement costs.

Conclusion

Selecting the right hydraulic hose fittings is paramount for the functionality of hydraulic systems. An OEM hydraulic hose fittings manufacturer offers the expertise, quality, and customized solutions necessary to ensure these systems operate at their best. With a focus on precision engineering, quality assurance, and compliance with industry standards, customers can trust OEM manufacturers to provide fittings that enhance the performance and reliability of their hydraulic applications. In a competitive industrial landscape, investing in high-quality hydraulic hose fittings is not just a smart choice—it is essential for success.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025