335345435

Feb . 01, 2025 03:59 Back to list

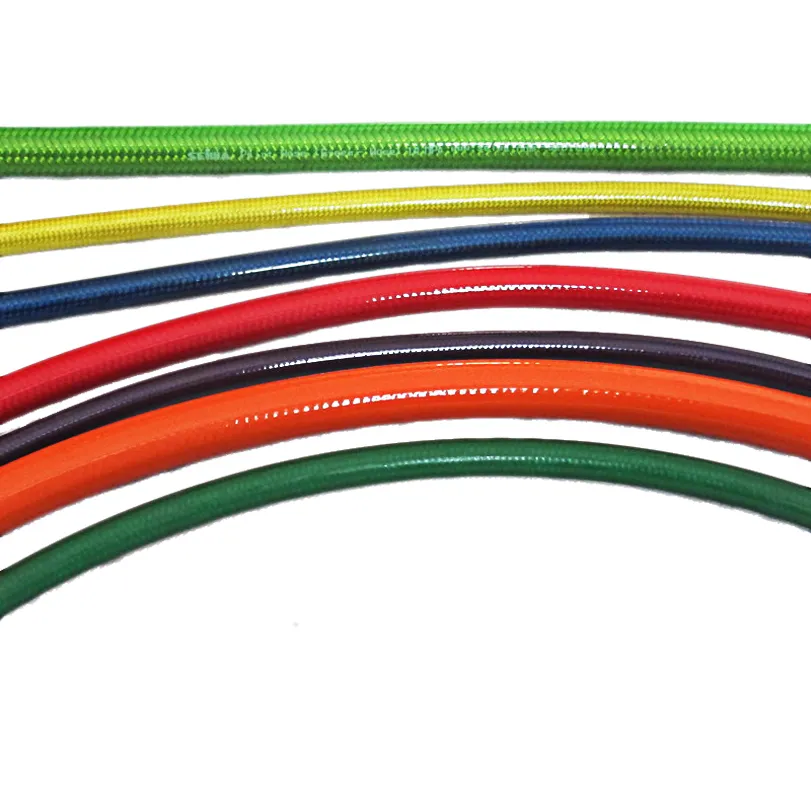

oem en 857 2sc hydraulic hose

OEM hydraulic hose fittings are often regarded as the lifeline in various industrial applications, ensuring seamless hydraulic system operations. Dive into this intricate world and discover how choosing the right fittings not only boosts your machinery's efficiency but also contributes to safety and longevity.

The authority of OEM hydraulic hose fittings is validated by their compliance with international standards set by organizations such as SAE International and the International Standards Organization (ISO). Ensuring that fittings meet these standards is crucial for maintaining not only the integrity of the system but also the safety of its operations. Trusted manufacturers routinely subject their fittings to rigorous testing processes. These include burst tests, impulse tests, and compatibility tests with various hydraulic fluids. Such stringent evaluations affirm that the fittings can withstand extreme temperatures, pressures, and environmental conditions, aspects critical in high-stake industries. Trustworthiness in OEM hydraulic hose fittings can be evaluated through manufacturer reputation and after-sales support. Established OEM manufacturers have a history of reliability and quality that new entrants may lack. Long-standing brands invest in R&D to innovate materials and designs that further enhance fitting performance. Additionally, robust customer support, warranty offers, and the availability of technical documentation from these manufacturers build confidence. When issues arise, having reliable customer service can expedite solutions, preventing prolonged downtimes that can be costly. Selecting OEM hydraulic hose fittings transcends basic procurement; it’s a strategic decision that impacts operational reliability. As systems evolve, so too does the technology behind fittings, demanding that stakeholders stay informed about the latest advancements and best practices. Investing in quality OEM fittings is an investment in productivity, safety, and long-term success, making it a cornerstone for anyone operating within hydraulically-driven environments.

The authority of OEM hydraulic hose fittings is validated by their compliance with international standards set by organizations such as SAE International and the International Standards Organization (ISO). Ensuring that fittings meet these standards is crucial for maintaining not only the integrity of the system but also the safety of its operations. Trusted manufacturers routinely subject their fittings to rigorous testing processes. These include burst tests, impulse tests, and compatibility tests with various hydraulic fluids. Such stringent evaluations affirm that the fittings can withstand extreme temperatures, pressures, and environmental conditions, aspects critical in high-stake industries. Trustworthiness in OEM hydraulic hose fittings can be evaluated through manufacturer reputation and after-sales support. Established OEM manufacturers have a history of reliability and quality that new entrants may lack. Long-standing brands invest in R&D to innovate materials and designs that further enhance fitting performance. Additionally, robust customer support, warranty offers, and the availability of technical documentation from these manufacturers build confidence. When issues arise, having reliable customer service can expedite solutions, preventing prolonged downtimes that can be costly. Selecting OEM hydraulic hose fittings transcends basic procurement; it’s a strategic decision that impacts operational reliability. As systems evolve, so too does the technology behind fittings, demanding that stakeholders stay informed about the latest advancements and best practices. Investing in quality OEM fittings is an investment in productivity, safety, and long-term success, making it a cornerstone for anyone operating within hydraulically-driven environments.

Share

Latest news

-

Premium Distribution PTFE Hose: Flexible & Durable Solutions

NewsAug.22,2025

-

SAE 100 R3 / EN854 R3 Hydraulic Hose | Medium Pressure & Flexible

NewsAug.11,2025

-

EN856 4SP Hydraulic Hose: High-Pressure & Durable Solutions

NewsAug.11,2025

-

Premium Soft Rubber Tubing: Flexible & Durable Hose Solutions

NewsAug.10,2025

-

Premium Distribution PTFE Hose | Flexible & Durable Solutions

NewsAug.09,2025

-

Premium 38mm Hydraulic Hose Factories | Direct & Reliable

NewsAug.08,2025