335345435

Jan . 17, 2025 02:38 Back to list

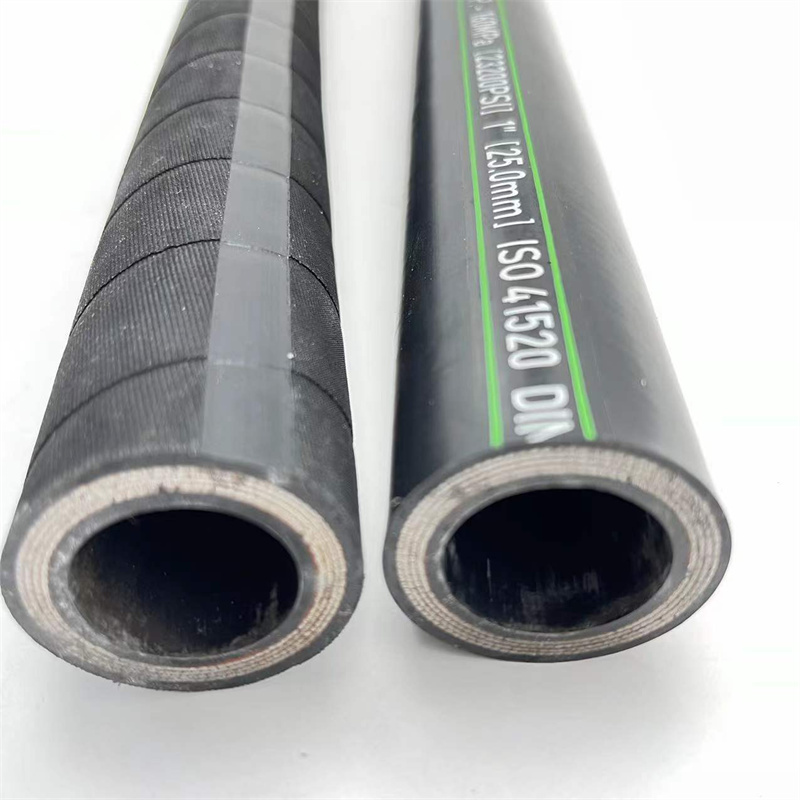

low temperature flexible hose

High temperature hydraulic hoses have become an essential component in various industrial applications, providing reliable and efficient means to convey fluids under extreme conditions. These hoses are specifically designed to withstand high temperatures, ensuring durability and performance in challenging environments.

In terms of authoritativeness, manufacturers of high temperature hydraulic hoses emphasize strict adherence to international standards and rigorous testing. Compliance with standards such as SAE (Society of Automotive Engineers), ISO (International Organization for Standardization), and DIN (Deutsches Institut für Normung) establishes a benchmark for quality, ensuring that each hose meets specific performance criteria. These standardized tests typically include burst pressure testing, thermal cycling, and fatigue resistance assessments. As a result, users can trust that these hoses will function effectively under the conditions for which they are rated. Trustworthiness in product performance also incorporates considerations of environmental impact and sustainability. The growing emphasis on eco-friendly operations has led to advancements in the manufacturing processes of hydraulic hoses. Leading manufacturers are now focusing on reducing the carbon footprint of their products by utilizing sustainable materials and energy-efficient production methods. Moreover, the longevity and resistance to extreme conditions offered by high temperature hydraulic hoses mean fewer replacements and less waste, further contributing to environmentally responsible practices. In conclusion, high temperature hydraulic hoses are indispensable in modern industrial settings. Their ability to endure extreme conditions without compromising on performance is a testament to advancements in material science and engineering. When selecting a hose for high temperature applications, it is vital to consider the product's material composition, compliance with industry standards, and the manufacturer's reputation for quality and sustainability. Investing in the right high temperature hydraulic hose not only enhances operational efficiency but also ensures safety and environmental responsibility, making them a pivotal choice for industries worldwide.

In terms of authoritativeness, manufacturers of high temperature hydraulic hoses emphasize strict adherence to international standards and rigorous testing. Compliance with standards such as SAE (Society of Automotive Engineers), ISO (International Organization for Standardization), and DIN (Deutsches Institut für Normung) establishes a benchmark for quality, ensuring that each hose meets specific performance criteria. These standardized tests typically include burst pressure testing, thermal cycling, and fatigue resistance assessments. As a result, users can trust that these hoses will function effectively under the conditions for which they are rated. Trustworthiness in product performance also incorporates considerations of environmental impact and sustainability. The growing emphasis on eco-friendly operations has led to advancements in the manufacturing processes of hydraulic hoses. Leading manufacturers are now focusing on reducing the carbon footprint of their products by utilizing sustainable materials and energy-efficient production methods. Moreover, the longevity and resistance to extreme conditions offered by high temperature hydraulic hoses mean fewer replacements and less waste, further contributing to environmentally responsible practices. In conclusion, high temperature hydraulic hoses are indispensable in modern industrial settings. Their ability to endure extreme conditions without compromising on performance is a testament to advancements in material science and engineering. When selecting a hose for high temperature applications, it is vital to consider the product's material composition, compliance with industry standards, and the manufacturer's reputation for quality and sustainability. Investing in the right high temperature hydraulic hose not only enhances operational efficiency but also ensures safety and environmental responsibility, making them a pivotal choice for industries worldwide.

Share

Latest news

-

Distribution PTFE Hose: Flexible, Chemical-Resistant Solutions

NewsAug.26,2025

-

SAE 100 R1AT Hydraulic Hose: Smooth, Wrapped & Colourful

NewsAug.25,2025

-

Premium Distribution PTFE Hose | Flexible & Stainless Braided

NewsAug.23,2025

-

Premium Distribution PTFE Hose: Flexible & Durable Solutions

NewsAug.22,2025

-

SAE 100 R3 / EN854 R3 Hydraulic Hose | Medium Pressure & Flexible

NewsAug.11,2025

-

EN856 4SP Hydraulic Hose: High-Pressure & Durable Solutions

NewsAug.11,2025