335345435

Sep . 30, 2024 17:08 Back to list

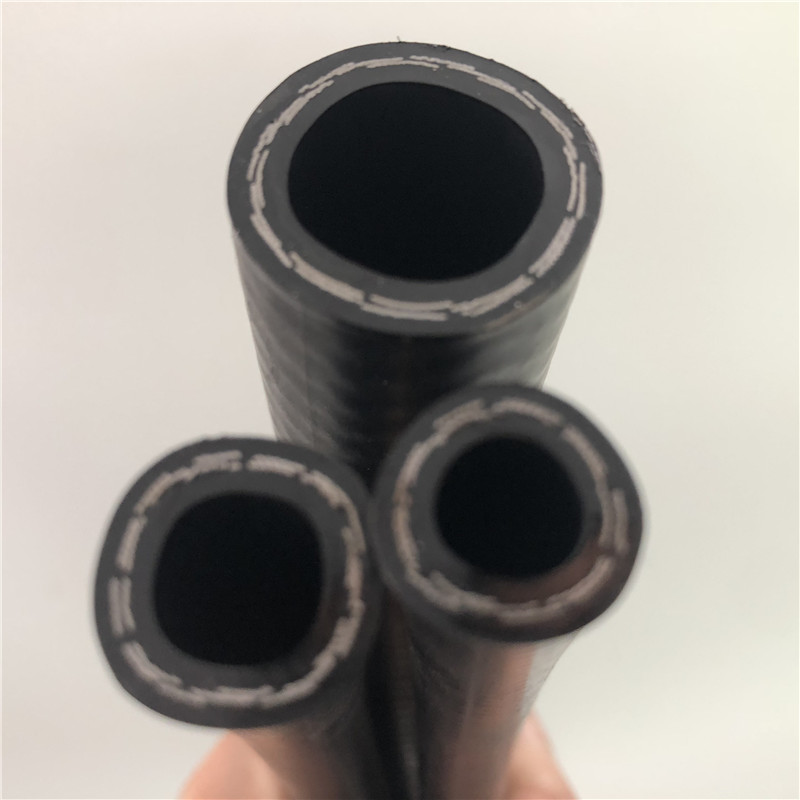

Custom High Pressure Rubber Hydraulic Hose Manufacturers for Flexible OEM Solutions

OEM Flexible High-Pressure Rubber Hydraulic Hose Manufacturers

In modern manufacturing, efficient and reliable hydraulic systems are crucial for a variety of industries, including construction, agriculture, and automotive. A key component of these systems is the hydraulic hose, which must be capable of withstanding high pressures while maintaining flexibility and durability. This is where Original Equipment Manufacturer (OEM) flexible high-pressure rubber hydraulic hoses play a crucial role. Understanding the characteristics, advantages, and manufacturers of these hoses can greatly benefit both manufacturers and end-users.

The Importance of High-Pressure Rubber Hydraulic Hoses

High-pressure rubber hydraulic hoses are specifically designed to transfer hydraulic fluids in a safe and efficient manner. They are essential for systems that operate under high pressure, typically exceeding 3000 psi. The primary function of these hoses is to connect various components of hydraulic systems, ensuring that power is transmitted without leaks or failure. The flexibility of these hoses allows for easier installation and movement, making them ideal for applications where space is limited or where components must be frequently repositioned.

Key Features of OEM Flexible High-Pressure Hydraulic Hoses

1. Material Composition OEM manufacturers typically use high-quality rubber compounded with various additives to enhance strength, resist environmental factors, and improve flexibility. Reinforcement layers, often composed of steel wires or fabrics, provide additional strength and pressure resistance.

2. Pressure Ratings These hoses come with specific pressure ratings suited for different applications. The appropriate hose must be selected based on the system's requirements to ensure safety and efficiency.

3. Temperature Resistance High-temperature environments can degrade standard hoses, but OEM manufacturers design their products to withstand a wide range of temperatures, ensuring durability and consistent performance even under extreme conditions.

4. Customizability OEM manufacturers often provide customization options based on the client's needs. This includes varying lengths, diameters, and fittings, allowing for compatibility with existing systems and enhancing performance.

5. Compliance with Standards OEM hoses typically adhere to international standards and certifications, ensuring that they meet safety and performance guidelines relevant to different industries.

Advantages of Sourcing from OEM Manufacturers

1. Quality Assurance OEM manufacturers are known for their stringent quality control processes. This results in hoses that are reliable and consistently perform to specification, minimizing the risk of failures that can lead to costly downtime.

oem flexible high pressure rubber hydraulic hose manufacturers

2. Tailored Solutions Working directly with OEM manufacturers allows customers to receive tailored solutions that meet specific operational demands. This can result in better system efficiency and longevity.

3. Technical Support OEM partnerships often come with access to technical expertise and support, helping customers select the right hoses for their applications and troubleshoot any issues that arise.

4. Cost-Effectiveness While initial costs may be higher than off-the-shelf solutions, the long-term savings from reduced maintenance and downtime can make OEM hoses a more cost-effective choice.

Choosing the Right Manufacturer

When selecting an OEM flexible high-pressure rubber hydraulic hose manufacturer, consider the following

1. Reputation and Experience Research the manufacturer’s history in the industry. Long-standing companies with a strong track record are often more reliable.

2. Product Range Check if the manufacturer offers a wide range of hoses and accessories that could cater to diverse applications.

3. Customer Service A manufacturer that provides excellent customer service, including post-purchase support, can help ensure the success of your hydraulic system.

4. Innovation Look for manufacturers that invest in research and development to create cutting-edge products that improve efficiency and safety.

Conclusion

The choice of OEM flexible high-pressure rubber hydraulic hoses can significantly impact the efficiency and reliability of hydraulic systems. By understanding the features, benefits, and considerations when selecting a manufacturer, businesses can ensure they invest in quality components that meet their specific needs. As industries continue to evolve, the demand for high-quality hydraulic hoses will persist, making it essential for manufacturers to develop cutting-edge, reliable solutions that support operational excellence.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025