335345435

Oct . 18, 2024 19:58 Back to list

OEM EN854 1TE Hose Manufacturers and Their Innovative Solutions for Industrial Applications

Understanding OEM EN854 1TE Manufacturers A Comprehensive Overview

In the realm of industrial machinery and equipment, the hoses used in applications can vastly differ based on the needs of the project. One such important specification is the EN854 1TE standard, a classification that defines the performance characteristics of hydraulic hoses. Original Equipment Manufacturers (OEMs) play a crucial role in providing these hoses, ensuring quality control, durability, and adaptability to various mechanical systems. This article delves into the significance of OEM EN854 1TE manufacturers, their products, and the intricate factors that influence their operations.

The Significance of EN854 1TE Standard

The EN854 standard pertains to the design and performance criteria for textiles and rubber hoses, particularly those that are used in hydraulic applications. The '1TE' designation typically refers to a specific type of textile-reinforced hose that is designed to handle high pressures while remaining flexible and resistant to wear. This versatility makes the EN854 1TE standard crucial for industries ranging from construction and agriculture to automotive and manufacturing.

Hydraulic systems require hoses that can withstand extreme conditions, including high pressure and temperature fluctuations. The EN854 1TE hoses are designed to meet these demands, providing reliability and safety in operations. The result is improved efficiency and reduced downtime, which are critical factors for any business reliant on heavy machinery.

The Role of OEM Manufacturers

OEMs specializing in EN854 1TE hoses are essential players in the supply chain for industrial equipment. These manufacturers design, produce, and distribute hoses that adhere to the EN854 1TE specifications, ensuring consistent quality across various applications. Their role extends beyond simple manufacturing; OEMs often engage in research and development to innovate new materials and designs that enhance the performance of these hoses.

Moreover, OEMs are tasked with ensuring that their products meet stringent quality controls and regulations. This ensures that the hoses are not only safe but also perform optimally in demanding environments. Collaboration with engineers and industry professionals enables OEMs to tailor their products to meet the evolving needs of users.

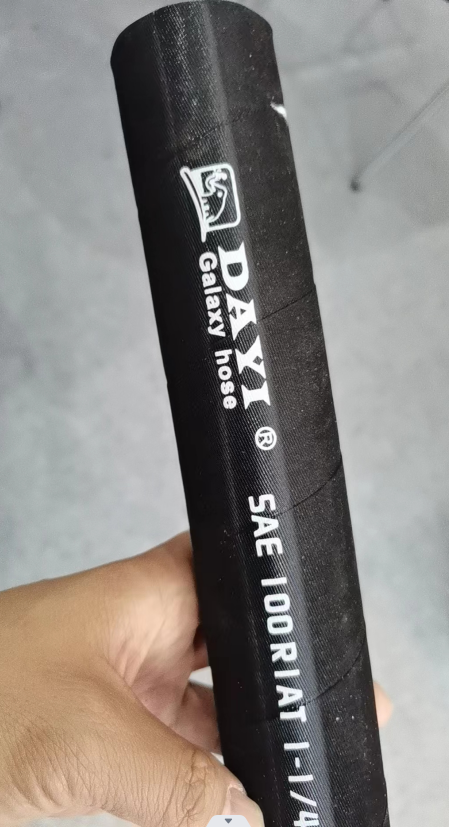

oem en854 1te manufacturers

Factors Influencing OEM EN854 1TE Manufacturing

Several factors influence the operations and output of OEM manufacturers producing EN854 1TE hoses. Among the most significant are material quality, technological advancements, and market demand.

1. Material Quality The properties of rubber and textile materials directly impact the durability and performance of the hoses. High-quality materials can withstand the stresses of hydraulic operations better than their counterparts. As technology progresses, OEMs can access new materials that offer enhanced resistance to wear, chemicals, and temperature extremes.

2. Technological Advancements Innovations in manufacturing processes, such as improved extrusion techniques and automation, lead to more consistent products with lower defect rates. These advancements also reduce production costs, allowing OEMs to offer competitive pricing while maintaining high standards.

3. Market Demand Understanding the market's needs is crucial for OEMs. Industries that rely on hydraulic systems are constantly evolving, with new applications and machinery designs that create demand for more specialized hoses. OEMs must stay attuned to these trends to ensure they are meeting consumer needs.

Conclusion

In conclusion, OEM EN854 1TE manufacturers play a vital role in the industrial landscape by providing high-quality hydraulic hoses essential for various applications. Their ability to innovate and adapt to changing market demands ensures that industries relying on hydraulic systems can operate efficiently and safely. As technology continues to advance and new challenges emerge, these manufacturers will remain pivotal in delivering solutions that meet the highest standards of performance and reliability.

-

High-Quality Distribution PTFE Hose for Industrial Applications

NewsJul.25,2025

-

High-Precision Hydraulic Hose Crimping Machine for Fast, Reliable Fittings

NewsJul.24,2025

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025