335345435

Déc . 09, 2024 22:57 Back to list

Steel Wire Spiral Hydraulic Hose Manufacturer in China for Durable Fluid Transfer Solutions

The Rise of China’s Steel Wire Spiral Hydraulic Hose Factory

The hydraulic hose industry has witnessed significant evolution and growth over the past few decades, particularly with the emergence of advanced manufacturing techniques and rising demand across various sectors. Among the key players in this sphere is China, which has become a dominant force in the production and supply of steel wire spiral hydraulic hoses. This article will explore the development of China's steel wire spiral hydraulic hose factories, their manufacturing processes, and the implications for both domestic and international markets.

Understanding Steel Wire Spiral Hydraulic Hoses

Steel wire spiral hydraulic hoses are vital components in hydraulic systems, primarily designed to handle high pressure and extreme temperature variations. These hoses are composed of a rubber or thermoplastic inner tube, reinforced with multiple layers of steel wire spirals, and covered with an external protective layer to enhance durability and resistance to abrasion. The robust construction allows them to operate safely under high pressure, making them indispensable in various applications, including construction, agriculture, and industrial machinery.

The Growth of Steel Wire Spiral Hydraulic Hose Manufacturing in China

China’s rise as a leading producer of hydraulic hoses can be attributed to several factors. Firstly, the country’s rapid industrialization has resulted in increased demand for hydraulic systems across numerous sectors, including manufacturing, mining, and transportation. This demand has encouraged factories to invest heavily in research and development, thereby improving production quality and efficiency.

Secondly, China is home to a vast supply chain that simplifies the sourcing of materials, including rubber, steel, and other essential components. The availability of low-cost labor also contributes to the competitive pricing of products, enabling manufacturers to cater to both domestic and international markets effectively.

Furthermore, advancements in manufacturing technologies, such as automation and precision engineering, have allowed Chinese factories to enhance their production capabilities. Modern machinery facilitates the consistent production of high-quality hydraulic hoses while reducing waste and production time. As a result, Chinese manufacturers can meet large orders and tightly manage inventory levels.

Manufacturing Processes

The manufacturing process of steel wire spiral hydraulic hoses typically involves several stages material selection, manufacturing of the hose itself, reinforcement with steel wire, and final testing

.china steel wire spiral hydraulic hose factory

1. Material Selection The first step involves selecting high-grade materials that meet international standards for durability and performance. Quality control checks are crucial throughout this phase to ensure that each component will endure the harsh conditions of hydraulic systems.

2. Hose Manufacturing The inner tube is created from synthetic rubber or thermoplastic polymers to ensure flexibility and resistance to hydraulic fluids. Automated machinery precision-engineers the inner tube, ensuring uniform thickness and strength.

3. Reinforcement with Steel Wire The critical process of reinforcing the hose involves winding layers of steel wire around the inner tube. This step is pivotal, as the number of wire layers determines the pressure rating of the final product. Advanced technologies allow for precise adjustments in wire tension, contributing to enhanced strength and reliability.

4. Testing and Quality Control After manufacturing, hydraulic hoses undergo rigorous testing to verify their pressure ratings and resistance to temperature fluctuations. Quality control ensures that only the best products are delivered to customers, preventing issues that could arise in the field.

Implications for Domestic and International Markets

The proliferation of steel wire spiral hydraulic hose manufacturing in China holds significant implications for both domestic and international markets. Domestically, the availability of high-quality, reasonably priced hydraulic hoses supports the growth of sectors that rely on hydraulic systems, ultimately bolstering the overall economy.

On the international stage, Chinese manufacturers often face competition from established suppliers in countries such as the United States and Germany. However, the combination of cost-efficiency and quality gives Chinese products a competitive edge. Many international companies have begun sourcing hydraulic hoses from China to reduce costs, thus creating strong trade relationships.

Conclusion

China's steel wire spiral hydraulic hose factories have established themselves as leaders in the global market through innovation, strategic resource management, and commitment to quality. As the demand for hydraulic systems continues to grow worldwide, China's manufacturing capabilities are likely to expand further, providing critical components that support a wide range of industries. The ongoing advancements in technology and production methods will ensure that these factories remain at the cutting edge, playing a pivotal role in shaping the future of hydraulic applications globally.

-

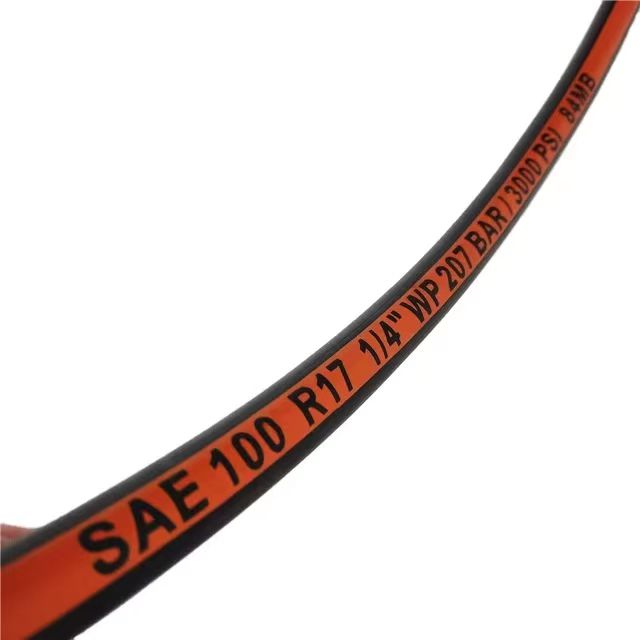

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025