335345435

joulu . 13, 2024 18:40 Back to list

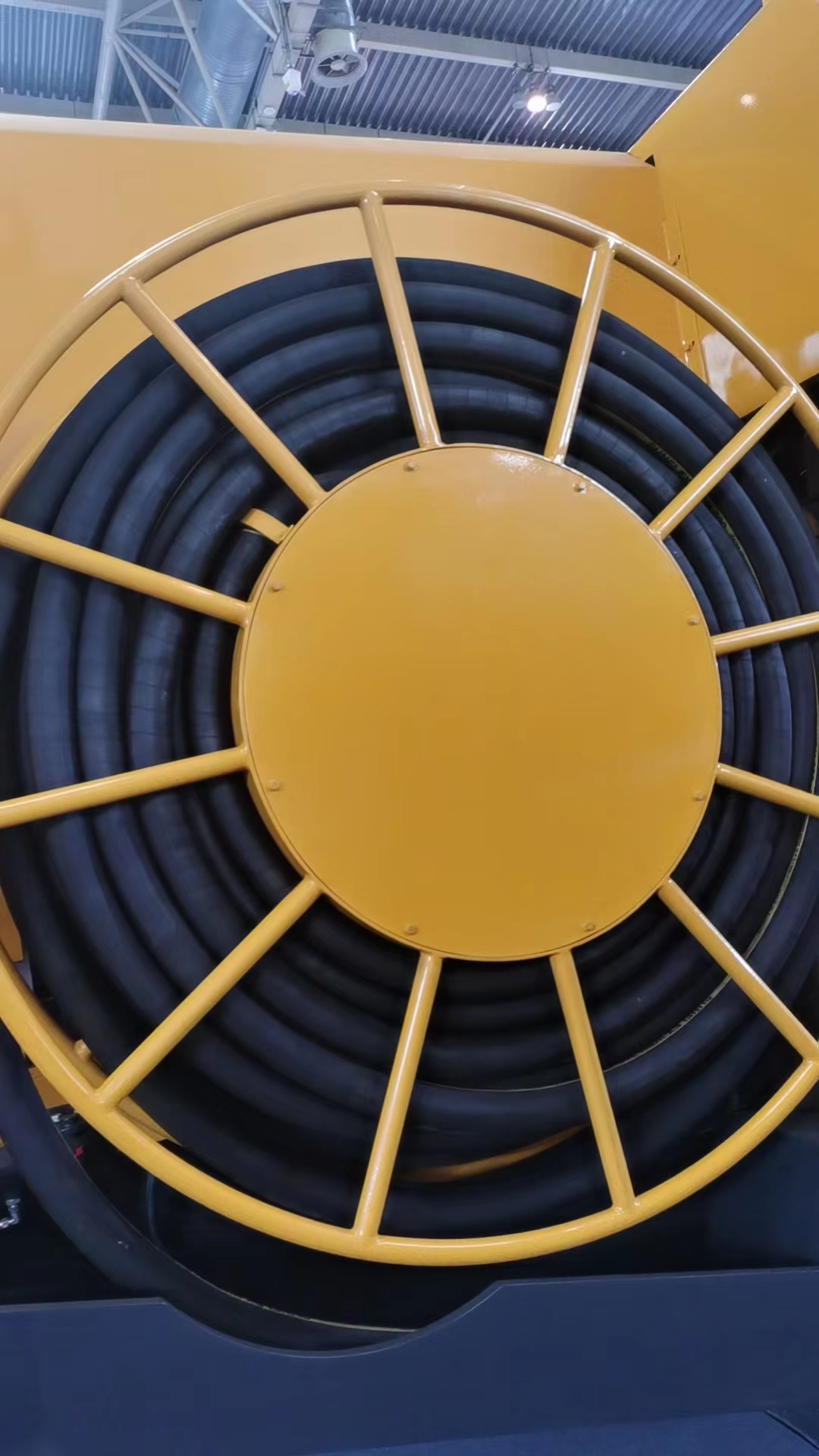

oem sae100r8 manufacturer

Understanding the OEM SAE 100R8 Hose Manufacturing Insights

The world of hydraulic hoses is vast and intricate, with various standards and specifications defining their performance and usability in different applications. One such standard, the SAE 100R8, is instrumental in various industries, including agriculture, construction, and manufacturing. This article delves into the characteristics, applications, and manufacturing processes of OEM (Original Equipment Manufacturer) SAE 100R8 hoses.

What is SAE 100R8?

SAE 100R8 is a specification established by the Society of Automotive Engineers (SAE) that outlines the construction and performance requirements for high-pressure hydraulic hoses. Unlike its predecessors, the SAE 100R8 is characterized by its thermoplastic construction, allowing for superior flexibility, lower weight, and improved resistance to external factors. These attributes make the SAE 100R8 hose an ideal choice for applications that demand resilience and adaptability.

One of the defining features of the SAE 100R8 hose is its construction. It consists of a thermoplastic inner tube, designed to handle a wide range of fluids, including hydraulic oils, water-based fluids, and some chemicals. The hose is reinforced with synthetic fibers, enhancing its strength and enabling it to withstand high-pressure conditions, often reaching up to 5,000 psi depending on the size and specifications.

Applications of SAE 100R8 Hoses

The versatility of SAE 100R8 hoses makes them suitable for numerous applications. In the agricultural sector, they are commonly used in agricultural machinery, ensuring the smooth operation of hydraulic systems that power tractors and other equipment. In construction, they facilitate the movement of hydraulic fluid in heavy machinery such as excavators and loaders, ensuring efficiency and safety on the job site.

Moreover, the SAE 100R8 hoses are also prevalent in the manufacturing sector. They are utilized in production processes where hydraulic systems are integral to machinery operation. The ability to withstand high pressures and various fluids without compromising integrity makes these hoses a reliable choice for manufacturers.

Manufacturing Process of SAE 100R8 Hoses

oem sae100r8 manufacturer

The manufacturing of OEM SAE 100R8 hoses involves several critical steps, each of which ensures the final product meets the stringent standards required for high-performance applications.

1. Material Selection The first step in the manufacturing process involves selecting high-quality thermoplastic materials that will serve as the internal tube and outer cover of the hose. These materials must exhibit excellent chemical compatibility and strength under pressure.

2. Extrusion After selecting the materials, the inner tube is formed using an extrusion process. This method allows for precise control over the hose's internal diameter and wall thickness, essential for maintaining its performance characteristics.

3. Reinforcement Once the inner tube is formed, layers of synthetic fibers are applied around it. This reinforcement is crucial; it ensures that the hose can withstand the high-pressure conditions it will encounter during use. The arrangement and tension of these fibers significantly influence the hose's durability and flexibility.

4. Outer Covering The outer layer of the hose is then extruded. This layer is vital for protecting the internal components from environmental factors such as abrasion, UV radiation, and chemical exposure. The choice of material for the outer cover often reflects the intended application of the hose.

5. Quality Assurance After manufacturing, each batch of hoses undergoes rigorous testing to ensure they meet the SAE 100R8 specifications. These tests assess the hose's ability to withstand pressure, flexibility, and chemical compatibility, ensuring safety and reliability in various applications.

6. Branding and Packaging Finally, the hoses are branded and packaged for distribution. OEM manufacturers ensure that their products are easily identifiable and come with the necessary documentation, including specifications and safety guidelines.

Conclusion

The OEM SAE 100R8 hose stands as a testament to the advances in hydraulic technology, combining flexibility, strength, and chemical resistance. Understanding its construction, application, and manufacturing process helps industries select the right hose for their needs, ensuring optimal performance and safety. As industries evolve, the demand for high-quality hydraulic solutions like the SAE 100R8 hose will only continue to grow, driving innovation in manufacturing and material science.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025