335345435

helmi . 06, 2025 03:01 Back to list

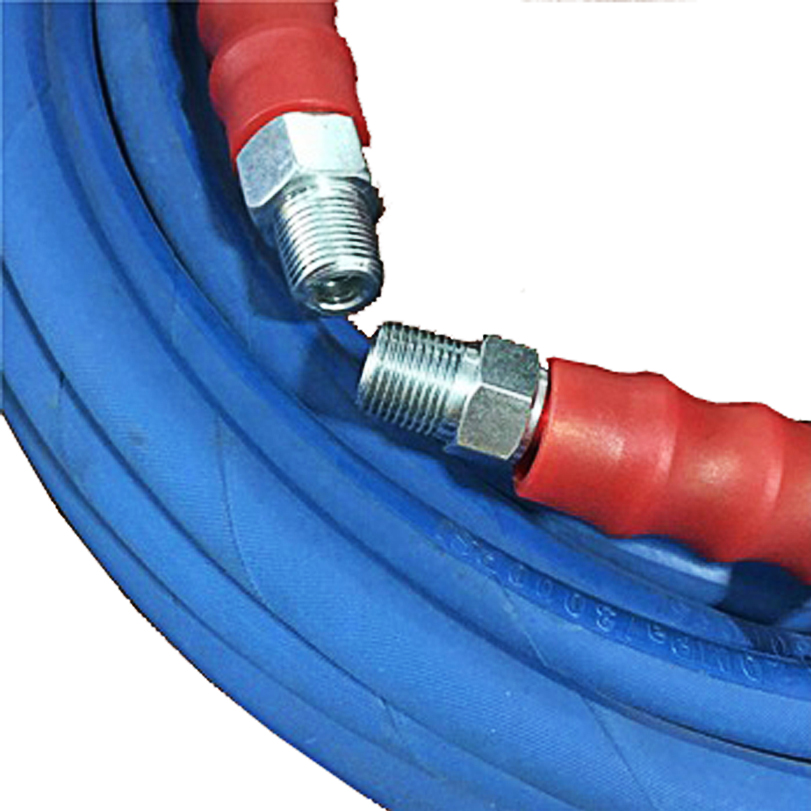

oem en 857 2sc hydraulic hose

Exploring the Dynamics of OEM SAE100R12 Hydraulic Hoses For Superior Performance and Reliability

Real-World Experience and Application Success Stories Across various industries, the practical application of OEM SAE100R12 hoses showcases a rich tapestry of success. In the construction field, companies have reported significant improvements in hydraulic system performance and reduced downtime when using these hoses. The hoses endure the strenuous demands of lifting and carrying heavy loads with reduced signs of wear and tear, even after extended use in demanding cycles. Moreover, agricultural sectors have also benefitted, using these hoses in equipment that requires high-pressure fluid transfer. The robust build and reliable performance translate to fewer maintenance requirements and longer operational periods, reflecting in overall cost savings. Trustworthiness and Long-Term Partnerships For any business, the decision to choose a particular component often boils down to trust in the product and the supplier. With OEM SAE100R12 hoses, businesses enjoy the peace of mind that comes from working with OEMs dedicated to excellence. These relationships provide not only quality products but also access to expert advice, customization options, and reliable after-sales support. Manufacturers often engage directly with clients to tailor hose specifications to fit precise application needs, ensuring optimal performance and satisfaction. Future Innovations and Evolving Standards The advancement in hydraulic hose technology does not halt at the current success of the SAE100R12. Research and development continue to enhance these products, focusing on increasing durability while reducing environmental impact. Innovations such as more sustainable rubber composites and advanced manufacturing techniques promise to deliver even more reliable solutions, aligning with future industry standards and ecological considerations. Conclusion The OEM SAE100R12 hoses stand as an indispensable component in the world of high-pressure hydraulic applications. With their exceptional build quality, adherence to authoritative standards, and proven field success, they offer an unmatched level of performance that professionals across several industries trust. As technology progresses, one can anticipate these hoses will only become more refined, continuously setting the benchmark for reliability and efficiency in hydraulic systems.

Real-World Experience and Application Success Stories Across various industries, the practical application of OEM SAE100R12 hoses showcases a rich tapestry of success. In the construction field, companies have reported significant improvements in hydraulic system performance and reduced downtime when using these hoses. The hoses endure the strenuous demands of lifting and carrying heavy loads with reduced signs of wear and tear, even after extended use in demanding cycles. Moreover, agricultural sectors have also benefitted, using these hoses in equipment that requires high-pressure fluid transfer. The robust build and reliable performance translate to fewer maintenance requirements and longer operational periods, reflecting in overall cost savings. Trustworthiness and Long-Term Partnerships For any business, the decision to choose a particular component often boils down to trust in the product and the supplier. With OEM SAE100R12 hoses, businesses enjoy the peace of mind that comes from working with OEMs dedicated to excellence. These relationships provide not only quality products but also access to expert advice, customization options, and reliable after-sales support. Manufacturers often engage directly with clients to tailor hose specifications to fit precise application needs, ensuring optimal performance and satisfaction. Future Innovations and Evolving Standards The advancement in hydraulic hose technology does not halt at the current success of the SAE100R12. Research and development continue to enhance these products, focusing on increasing durability while reducing environmental impact. Innovations such as more sustainable rubber composites and advanced manufacturing techniques promise to deliver even more reliable solutions, aligning with future industry standards and ecological considerations. Conclusion The OEM SAE100R12 hoses stand as an indispensable component in the world of high-pressure hydraulic applications. With their exceptional build quality, adherence to authoritative standards, and proven field success, they offer an unmatched level of performance that professionals across several industries trust. As technology progresses, one can anticipate these hoses will only become more refined, continuously setting the benchmark for reliability and efficiency in hydraulic systems.

Share

Latest news

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025