335345435

marras . 23, 2024 18:52 Back to list

oem black wire braid hydraulic hose manufacturer

Exploring the OEM Black Wire Braid Hydraulic Hose A Guide to Manufacturers and Applications

In the world of hydraulic systems, the reliability and performance of hoses play a crucial role. Among the various types available, the OEM black wire braid hydraulic hose stands out as a popular choice due to its durability, flexibility, and the ability to withstand high pressures. This article will delve into the specifics of this type of hose, its manufacturing process, and the applications it serves.

What is OEM Black Wire Braid Hydraulic Hose?

The term OEM stands for Original Equipment Manufacturer, which signifies that the product is designed to meet the specifications set by original equipment manufacturers. The black wire braid hydraulic hose incorporates layers of high tensile steel wire braiding, providing it with immense strength and pressure resistance. The outer rubber sheath is typically made from synthetic rubber, which offers excellent resistance to abrasions, weather, and hydraulic fluids.

Advantages of Black Wire Braid Hydraulic Hoses

1. High Pressure Resistance One of the most significant advantages of black wire braid hydraulic hoses is their ability to handle high-pressure applications. This makes them ideal for industries such as construction, mining, and manufacturing, where there are extreme service conditions.

2. Durability The steel wire braid reinforces the hose, protecting it against impacts and external wear. This durability extends the hose's lifespan, reducing the need for frequent replacements and maintenance.

3. Flexibility Despite their robust construction, these hoses are designed to maintain flexibility, allowing for easy installation and routing in restricted spaces. Operators can maneuver them around corners and tight spots without compromising performance.

4. Heat and Oil Resistance The materials used in the production of black wire braid hoses are resistant to heat and oil, ensuring they can perform well even in environments where these factors could lead to hose failure.

Manufacturing Process

The manufacturing process of OEM black wire braid hydraulic hoses involves multiple stages that ensure quality and efficiency

.1. Material Selection The process begins with the careful selection of quality raw materials, including synthetic rubber and steel wires. Manufacturers must ensure that these materials meet the required industry standards.

oem black wire braid hydraulic hose manufacturer

2. Extrusion The rubber is then extruded into a tube to form the core of the hose. This step is critical because the thickness and quality of the core will directly impact the hose's performance.

3. Wire Braiding Following extrusion, the steel wire is braided around the hose. This is a crucial step that provides reinforcement and enhances the hose's ability to withstand high pressures.

4. Cover Application An additional layer of rubber is applied over the braided wire. This layer offers protection against abrasion, weather, and chemical exposure.

5. Testing Before the hoses are shipped out, they undergo rigorous testing to ensure they meet safety and performance standards. Tests include pressure testing, impulse tests, and flexibility assessments.

Applications

OEM black wire braid hydraulic hoses are versatile and can be found in various applications across multiple industries

1. Construction Equipment These hoses are commonly used in construction machinery, such as excavators, bulldozers, and cranes, where reliability under pressure is paramount.

2. Agricultural Machinery In farming equipment like tractors and combines, these hoses play a vital role in hydraulic systems, ensuring efficient operation.

3. Industrial Applications Manufacturing facilities utilize these hoses in machines that require hydraulic power for operation, facilitating tasks ranging from lifting to automated processes.

4. Automotive Systems In the automotive industry, they are used in hydraulic brakes and steering systems, where safety is of utmost importance.

Conclusion

The OEM black wire braid hydraulic hose is an essential component in many industrial applications. Its high pressure resistance, durability, and versatility make it a reliable choice for manufacturers and operators alike. When choosing a manufacturer for these hoses, it is crucial to consider their reputation, product quality, and adherence to industry standards to ensure that you receive a reliable product for your needs. In a world where efficiency and safety are paramount, investing in quality hydraulic hoses is a decision that pays off in the long run.

-

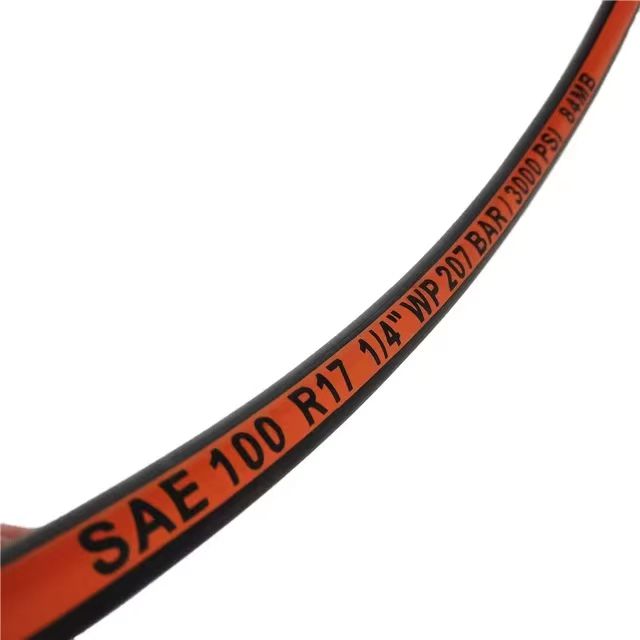

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025