335345435

joulu . 28, 2024 07:31 Back to list

hydraulic hose fitting manufacturer supplier

The Importance of Hydraulic Hose Fitting Manufacturers and Suppliers

In the industrial and construction sectors, hydraulic systems play a pivotal role in powering machinery and facilitating operations. These systems rely heavily on hydraulic hoses and fittings, which are essential components that ensure fluid transfer, pressure regulation, and efficient system performance. As industries grow and evolve, the demand for high-quality hydraulic hose fittings has surged, making the role of manufacturers and suppliers increasingly vital.

Understanding Hydraulic Hose Fittings

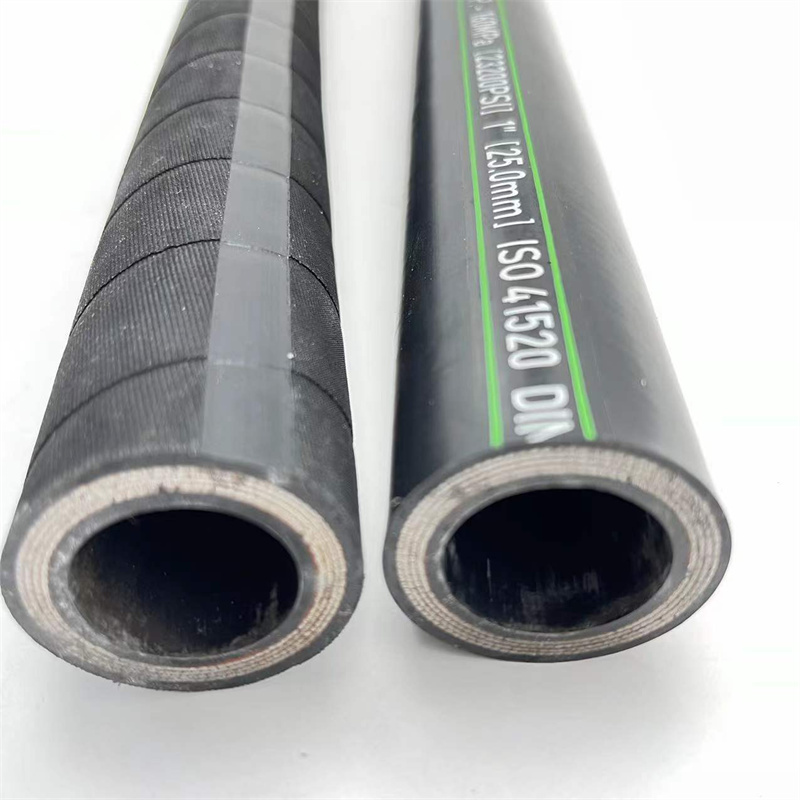

Hydraulic hose fittings serve as crucial connectors within hydraulic systems. They are designed to couple hoses to various components such as pumps, valves, actuators, and other machinery. These fittings come in a variety of shapes and sizes, catering to the specific needs of different hydraulic applications. The primary materials used in producing these fittings include steel, stainless steel, brass, and even plastic, depending on the application requirements, including pressure ratings and environmental resistance.

The Role of Manufacturers

Manufacturers of hydraulic hose fittings are responsible for producing components that meet stringent safety and performance standards. These manufacturers invest in advanced technology and processes to ensure that their products can withstand extreme pressure and conditions. Quality control is paramount, as the failure of a single fitting can lead to catastrophic results, not only damaging equipment but also posing serious safety hazards to operators.

In addition to producing standard fittings, many manufacturers offer customizable solutions tailored to meet the specific needs of clients. This flexibility is crucial in an industrial landscape where diverse machinery and unique operational challenges require bespoke fittings. Manufacturers often work closely with engineers and designers to develop specialized products that enhance the efficiency and safety of hydraulic systems.

hydraulic hose fitting manufacturer supplier

The Role of Suppliers

While manufacturers produce the fittings, suppliers play a crucial role in ensuring that these components reach the end-users. Suppliers operate at various levels, from local distributors to global supply chain agents. They stock a wide range of hydraulic hose fittings and other related components, allowing customers to find what they need quickly and efficiently.

Suppliers also provide vital services such as inventory management, logistical support, and technical assistance. Many have dedicated teams of experts who can advise clients on choosing the right fittings for their systems, based on factors such as pressure requirements, compatibility with compatible materials, and environmental conditions.

Importance of Quality and Compliance

Quality and compliance are non-negotiable in the hydraulic hose fitting industry. Manufacturers and suppliers must ensure that their products adhere to relevant industry standards, such as ISO, SAE, and ASTM. Non-compliance can lead to product recalls, legal liabilities, and damage to reputation. As such, reputable companies prioritize certifications and continuous improvement practices to enhance product safety and performance.

Conclusion

In conclusion, hydraulic hose fitting manufacturers and suppliers are essential to the functionality and safety of hydraulic systems across various sectors. Their commitment to quality, innovation, and customer service enables industries to operate smoothly and efficiently. As technology advances and industries evolve, the role of these manufacturers and suppliers will only grow, paving the way for more sophisticated, safe, and efficient hydraulic solutions. By choosing the right partners in hydraulic hose fittings, businesses can ensure their operations remain productive and hazard-free, contributing to overall success in their respective fields.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025