335345435

loka . 16, 2024 06:50 Back to list

high pressure steel wire braided hydraulic hose manufacturers

High-Pressure Steel Wire Braided Hydraulic Hose Manufacturers

High-pressure steel wire braided hydraulic hoses are essential components in various industrial applications, providing reliable fluid transfer under extreme conditions. The manufacturing of these hoses requires a blend of advanced technology, skilled labor, and stringent quality control processes. As a result, manufacturers of high-pressure hydraulic hoses play a critical role in ensuring safety and efficiency in hydraulic systems across multiple sectors.

The structure of a high-pressure hydraulic hose typically consists of an inner tube made of synthetic rubber or thermoplastic, which is resistant to the fluids being conveyed. Surrounding this inner tube, multiple layers of steel wire braid are tightly woven. This construction provides exceptional tensile strength and crush resistance, allowing the hose to withstand high pressure, often exceeding 5000 psi. Additionally, an outer cover is applied to protect against abrasion, weather, and various chemicals.

Manufacturers specializing in high-pressure steel wire braided hydraulic hoses focus on several key factors. First, sourcing high-quality raw materials is crucial. The steel wire must be durable and corrosion-resistant to ensure a long service life. Second, precision in the manufacturing process is vital. This includes controlling the braiding process to achieve the right density and pattern, as well as ensuring that the hose maintains uniform dimensions and flexibility.

high pressure steel wire braided hydraulic hose manufacturers

Quality control is another critical aspect of manufacturing hydraulic hoses. Reputable manufacturers conduct rigorous testing on their products, including pressure tests, burst tests, and abrasion resistance tests. These evaluations help to guarantee that the hoses meet industry standards and customer requirements. By adhering to international quality standards such as ISO and SAE, manufacturers enhance their credibility and trustworthiness in the market.

Furthermore, advancements in technology have significantly impacted the production of hydraulic hoses. Automation and computer-aided design (CAD) have streamlined manufacturing processes, increasing efficiency and reducing production time. Additionally, innovations such as hydraulic hose assemblies with integrated sensors offer improved monitoring of fluid flow and pressure, contributing to proactive maintenance and reduced downtime.

In conclusion, high-pressure steel wire braided hydraulic hose manufacturers are vital to various industries including construction, agriculture, and aviation. Their commitment to quality, technology, and innovation ensures that hydraulic systems operate safely and efficiently. As industries continue to evolve and demand higher performance, these manufacturers will play a pivotal role in delivering the necessary solutions to meet the growing challenges of fluid transfer in high-pressure environments.

-

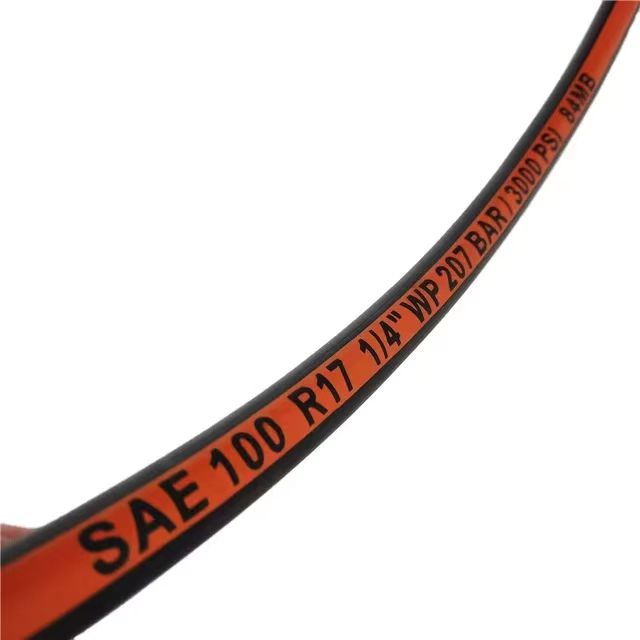

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025