335345435

دسامبر . 11, 2024 00:42 Back to list

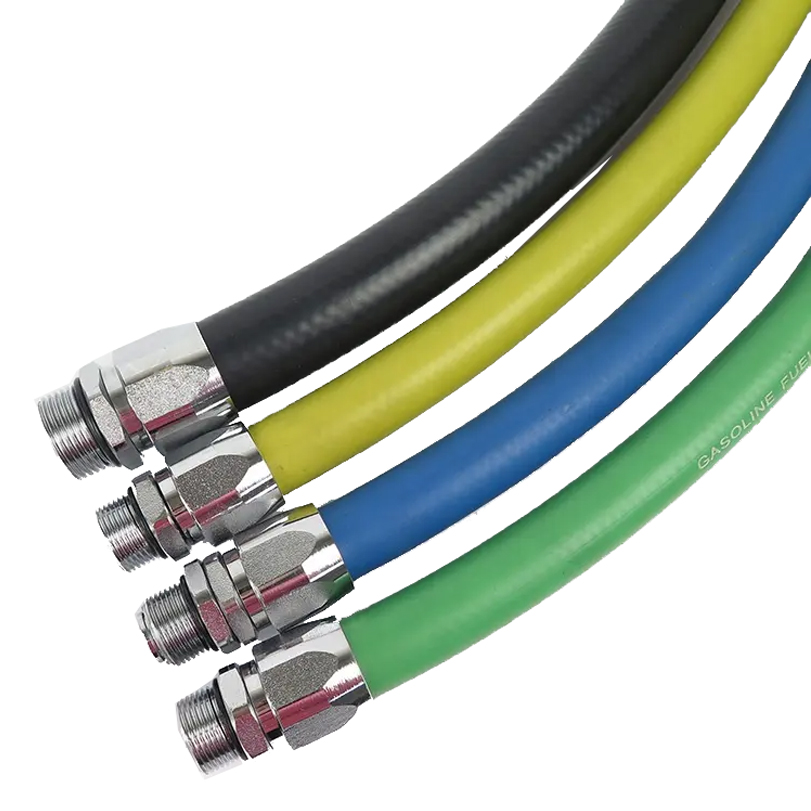

High-Performance OEM Parker Teflon Hose Solutions for Various Applications

The Versatility and Importance of OEM Parker Teflon Hoses

In the world of industrial applications, the choice of materials for hoses can significantly impact performance, safety, and reliability. One popular choice in a variety of industries is the OEM Parker Teflon hose. These hoses are known for their exceptional durability, resistance to chemical degradation, and ability to handle extreme temperatures. Below, we will delve into the features, benefits, applications, and installation considerations associated with OEM Parker Teflon hoses.

Features of OEM Parker Teflon Hoses

OEM Parker Teflon hoses are constructed from polytetrafluoroethylene (PTFE), a high-performance plastic renowned for its unique properties. The primary features that set these hoses apart include

1. Chemical Resistance Teflon is known for its ability to withstand a wide range of chemicals without degrading. This provides an added layer of safety and longevity in environments where harsh chemicals are present, making it ideal for chemical processing, food and beverage production, and pharmaceuticals.

2. Temperature Tolerance OEM Parker Teflon hoses can handle extreme temperature fluctuations, withstanding temperatures from -320°F to 500°F (-196°C to 260°C). This wide temperature range ensures that these hoses perform reliably in high-heat applications, such as steam and hot water systems.

3. Low Friction The non-stick surface of Teflon hoses minimizes resistance, allowing for smooth fluid flow and reducing the energy required for pumping. This feature is particularly beneficial in applications requiring high flow rates or in systems where pressure loss must be minimized.

4. Flexibility and Strength Despite their lightweight nature, OEM Parker Teflon hoses maintain exceptional tensile strength, making them resistant to kinking or crushing. They also feature a flexible design that allows for easy installation in tightly confined spaces.

5. FDA Compliance For applications in the food and beverage sector, OEM Parker Teflon hoses are often manufactured to meet FDA standards, ensuring they are safe for food contact and do not impart any contaminants.

Applications of OEM Parker Teflon Hoses

The versatility of Teflon hoses makes them suitable for a diverse set of applications across various industries

oem parker teflon hose

- Chemical Handling For the transportation of corrosive substances, OEM Parker Teflon hoses provide a safe solution that minimizes the risk of leaks or material degradation.

- Food and Beverage These hoses are particularly valuable in food processing applications, where hygiene and compliance with health regulations are paramount. The non-reactive nature of Teflon eliminates concerns about contamination.

- Pharmaceuticals In pharmaceutical manufacturing and handling, the purity of the materials used is crucial. OEM Parker Teflon hoses help ensure that the products remain uncontaminated during processing.

- Aerospace and Automotive Teflon hoses are commonly employed in aerospace and automotive applications due to their ability to withstand extreme conditions, including high pressures and varying temperatures.

- Marine Applications The marine industry utilizes these hoses for fuel lines and other applications that require resistance to harsh environments and chemicals.

Installation and Maintenance Considerations

Proper installation and maintenance of OEM Parker Teflon hoses are essential for ensuring their longevity and performance. Before installation, it is critical to assess the environment and specific requirements of the application to select the appropriate hose size, type, and fittings.

- Installation Ensure that the hose is installed with appropriate support to avoid unnecessary stress at bends and connections. Using quality fittings and clamps suited for PTFE is crucial for preventing leaks.

- Maintenance Regular inspections should be conducted to check for signs of wear, cracks, or abrasions. Given their durability, Teflon hoses typically require less frequent replacement compared to traditional rubber hoses.

Conclusion

In summary, OEM Parker Teflon hoses are an essential component in various industrial applications due to their remarkable properties, including chemical resistance, temperature tolerance, and flexibility. Their usage across multiple sectors, from food processing to pharmaceuticals, underscores their importance in ensuring safety and reliability. By adhering to proper installation and maintenance procedures, companies can maximize the lifespan and performance of these invaluable hoses, ultimately contributing to improved efficiency and productivity in their operations.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025