335345435

اکتبر . 22, 2024 07:10 Back to list

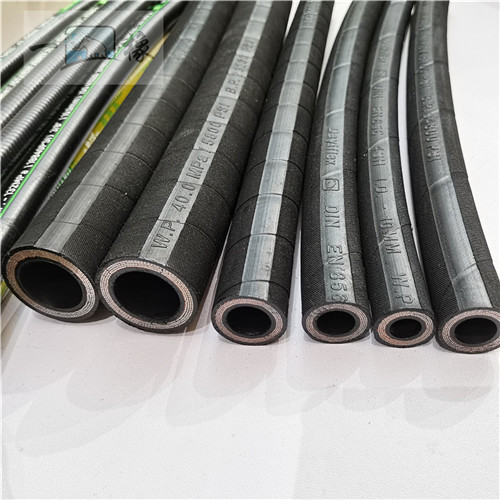

OEM Hydraulic Hose and Fittings Manufacturing Solutions for Optimal Performance

The Importance of OEM Hydraulic Hose and Fittings Factories

In the realm of industrial applications, hydraulic systems play a pivotal role in enabling machines and equipment to function effectively. At the heart of these systems are hydraulic hoses and fittings, essential components that ensure the safe and efficient transfer of hydraulic fluids. As the demand for high-quality hydraulic components continues to rise, Original Equipment Manufacturer (OEM) hydraulic hose and fittings factories have become critical players in the industry.

Understanding Hydraulic Systems

Hydraulic systems utilize pressurized fluids to perform work through various mechanical components. They are commonly found in heavy machinery, construction equipment, agricultural machines, and even in automotive applications. The effectiveness of these systems hinges on the reliability of hydraulic hoses and fittings, which must withstand high pressures and harsh operating conditions.

The Role of OEM Manufacturers

OEM manufacturers specialize in creating components that are designed to fit specific machines and systems. Unlike aftermarket parts, which may not always match original specifications, OEM products are engineered to meet exact standards set by equipment manufacturers. This ensures optimal performance, safety, and longevity.

OEM hydraulic hose and fittings factories are equipped with state-of-the-art technology and skilled personnel who understand the rigorous demands of hydraulic applications. They are responsible for producing hoses that can endure extreme temperatures, varying pressures, and exposure to harsh chemicals. Quality control is paramount in these factories, as any defects in the hoses or fittings can lead to equipment failure and safety hazards.

The Advantages of Choosing OEM Components

1. Precision Engineering OEM hydraulic hoses and fittings are designed with precision to ensure they fit seamlessly into the specific machinery they are intended for. This tailored design minimizes the risk of failure due to improper fitting or compatibility issues.

oem hydraulic hose and fittings factory

2. Quality Assurance OEM manufacturers adhere to strict quality standards in their production processes. This means that the components are rigorously tested for durability, flexibility, and resistance to wear and tear, thus promoting reliable performance in demanding applications.

3. Long-Term Cost Efficiency While OEM components may come with a higher initial price tag compared to aftermarket options, their durability and reliability can lead to significant cost savings in the long run. Fewer replacements mean less downtime and reduced maintenance costs.

4. Access to Technical Support OEM manufacturers often provide technical support and guidance to their customers. This can be invaluable when troubleshooting issues or making decisions about system upgrades and renovations.

Innovations in Hydraulic Technology

As industries continue to evolve, so do the technologies used in hydraulic systems. OEM hydraulic hose and fittings factories are at the forefront of these advancements, investing in research and development to create innovative products that meet the changing needs of the market. This includes developing hoses with improved materials that enhance flexibility and resistance to abrasions, as well as fittings that offer superior sealing capabilities.

Moreover, sustainability has become a key focus for many OEM manufacturers. They are increasingly exploring environmentally friendly materials and processes to reduce their carbon footprint while still maintaining high performance standards.

Conclusion

In conclusion, OEM hydraulic hose and fittings factories play an essential role in the efficiency and safety of hydraulic systems across various industries. The precision, quality assurance, and technological innovations they bring to the table are critical in meeting the demands of modern machinery. As industries continue to advance, the importance of relying on high-quality OEM components will only grow, ensuring that machines operate at their best while safeguarding the well-being of workers and the environment. Choosing OEM hydraulic hoses and fittings not only enhances performance but also contributes to a more sustainable future in industrial operations.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025