335345435

Dic . 17, 2024 10:06 Back to list

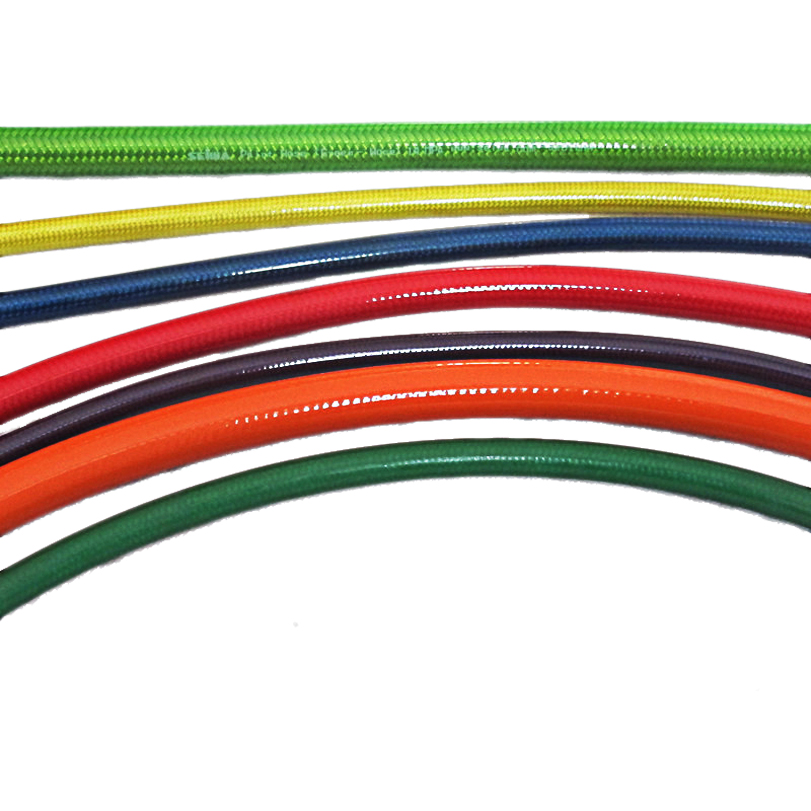

fuel hose high pressure

Understanding High-Pressure Fuel Hoses Applications, Design, and Safety Considerations

In the realm of automotive and aerospace engineering, the functionality and reliability of fuel delivery systems are paramount. One critical component of these systems is the fuel hose, particularly high-pressure fuel hoses, which are essential for ensuring safe and efficient fuel transfer in high-demand environments. This article explores the design, applications, and safety considerations associated with high-pressure fuel hoses.

Design and Construction

High-pressure fuel hoses are specifically engineered to withstand the intense conditions found within fuel systems. They are typically constructed from reinforced materials such as synthetic rubber, thermoplastics, or metal, which provide both flexibility and strength. The internal layers are designed to resist fuel permeation and damage from heat and chemicals, while the outer layer is often treated to withstand abrasion and environmental exposure.

The reinforcement in high-pressure hoses often consists of woven fibers or coils of steel, allowing these hoses to operate safely at pressures exceeding 300 psi (pounds per square inch) or even higher in specialized applications. This construction enables the hoses to maintain structural integrity under pressure fluctuations often seen during operation, such as sudden stops or accelerations.

Applications

High-pressure fuel hoses are utilized across various industries. In automotive applications, they are found in fuel injection systems, where fuel is pumped at high pressures to ensure efficient combustion. The integration of high-pressure fuel hoses is crucial in modern vehicles, particularly in turbocharged engines that require more fuel to maintain performance under increased pressure.

In aviation, high-pressure hoses are equally vital. Aircraft fuel systems operate under high pressure to manage the large volumes of fuel required for long-haul flights. The reliability of these hoses ensures that the fuel is delivered efficiently from the tanks to the engines, thus contributing to the overall safety of the flight.

fuel hose high pressure

Additionally, high-pressure fuel hoses are extensively used in racing and motorsports. Here, the demands are heightened, and performance optimization is critical. These hoses must not only handle high pressures but also maintain flexibility and light weight, ensuring that they do not hinder vehicle performance.

Safety Considerations

While high-pressure fuel hoses are designed for durability and performance, safety remains a primary concern. Over time, factors such as environmental stress, exposure to chemicals, and mechanical wear can compromise the integrity of these hoses. Regular inspections are vital to identify any signs of wear, including cracks, bulges, or leaking fuel. Any damaged hoses should be replaced immediately to mitigate the risk of accidents or system failures.

Moreover, it is essential to adhere to proper installation practices. High-pressure hoses must be routed and secured adequately to prevent kinking or pinching, which can lead to catastrophic failures. Additionally, using appropriate fittings and clamps designed for high pressure is crucial to maintaining the efficacy of the entire fuel system.

Furthermore, when working with high-pressure fuel hoses, one must be aware of the potential hazards associated with fuel leaks. Combustible fuel paired with high pressure poses significant fire risks. Thus, adhering to professional standards and nomenclatures during any repairs or replacements is necessary for maintaining safety in fuel management systems.

Conclusion

High-pressure fuel hoses are a vital component in various applications, from automotive to aviation and motorsports. Their specialized design allows them to withstand the rigors of high-pressure environments, ensuring efficient fuel delivery. However, safety should always be at the forefront of any fuel management system. Regular inspection, proper installation, and adherence to professional standards can mitigate risks associated with high-pressure fuel hoses. As technology advances, the development of even more resilient materials and innovative designs will further enhance the reliability and safety of fuel systems in the future.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025